Environment-friendly salt-resistant high-temperature-resistant oil displacement agent containing biological surfactant and used in petrochemical industry

A petrochemical and surfactant technology, applied in chemical recovery, drilling compositions, chemical instruments and methods, etc., can solve the problem that the oil displacement agent cannot be degraded, the amount of use is large, and the oil displacement agent cannot be effectively and reliably exploited To achieve the effect of improving oil displacement efficiency and sweep coefficient, reducing raw material cost, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

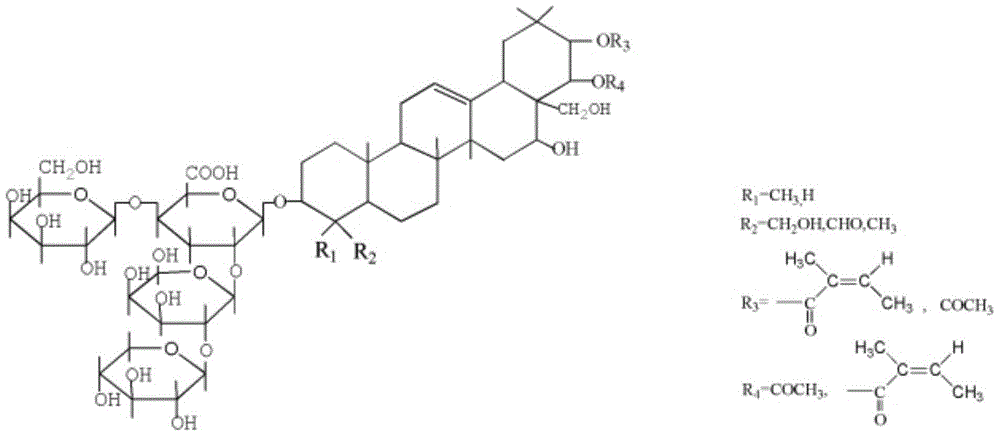

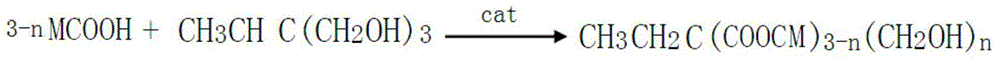

[0029] Heat the tea saponin mother liquor extracted from tea dregs and trimethylolpropane to 90-95°C in a mixing reactor, react under the catalysis of cerium sulfate, recover the catalyst after the reaction is complete, and concentrate to obtain tea soap Plain modifier, wherein tea saponin and trimethylol propane carry out mixing reaction according to the molar ratio of 3.5:1.

Embodiment 2

[0031] Mix and react the tea saponin mother liquor and thionyl chloride in a mixing reactor at a reaction temperature of 20-25°C, wherein the tea saponin and thionyl chloride are mixed and reacted at a molar ratio of 1.1:1; After the end, add trimethylolpropane and carry out mixed reaction at 40-45°C. The amount of trimethylolpropane added is 1 / 3 of that of thionyl chloride. After the reaction is complete, concentrate to obtain the tea saponin modifier.

Embodiment 3

[0033] Heat the tea saponin mother liquor extracted from tea dregs and trimethylolpropane to 90-95°C in a mixing reactor, and react under the catalysis of activated carbon-supported p-toluenesulfonic acid catalyst, and recover the catalyst after the reaction is complete After concentration, the tea saponin modifier is obtained, wherein the tea saponin and trimethylolpropane are mixed and reacted according to the molar ratio of 3.5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com