A method for preparing conductive polymer composite material with isolation structure

A technology of polymer materials and conductive polymers, which is applied in the field of preparing conductive polymer composite materials with an isolation structure, can solve the problems of high conductive polymer composite material production efficiency and low percolation value, and achieve easy popularization and application, over The effect of low bleed value and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0039] Embodiment 1-6 Preparation of Conductive Polymer Composite Material with Isolation Structure

[0040] Concrete preparation steps are:

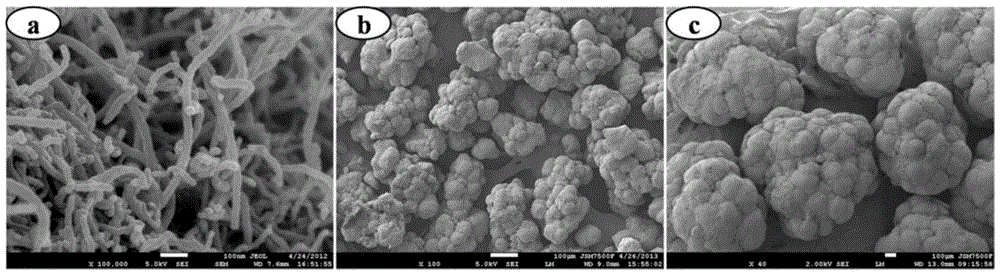

[0041] (1) Pretreatment of multi-walled carbon nanotubes (CNTs): 20g of CNTs will be weighed on an analytical balance, then put into an open petri dish, put the petri dish into an oven, and set the oven temperature to 50 °C for 2 hours; then put the dried CNTs into ziplock bags and seal them for the next step.

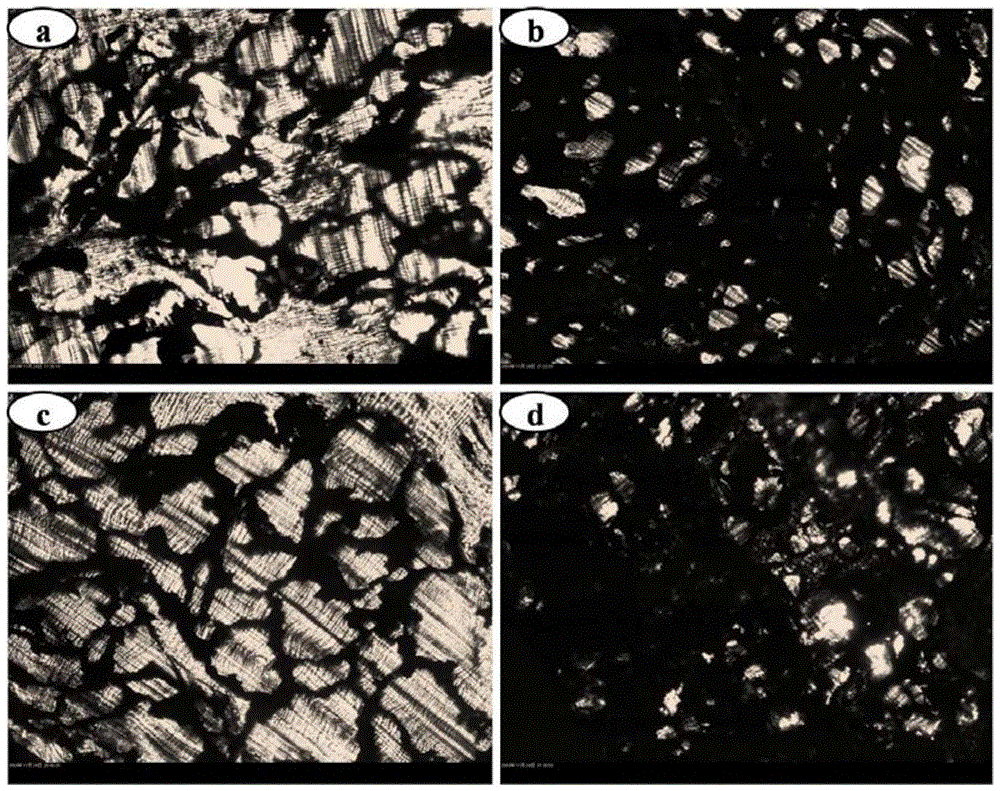

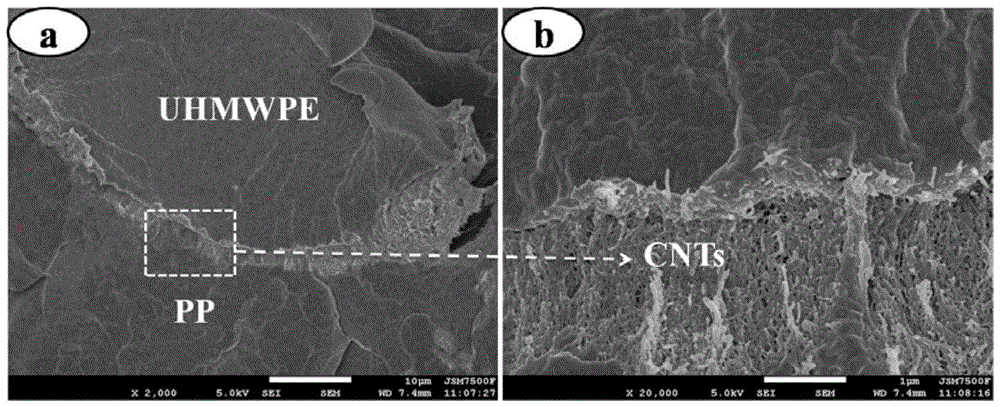

[0042] (2) Preparation of CNTs / iPP / UHMWPE mixture: In order to make the mixture grind as fully as possible and maintain the consistency of the experimental conditions, the total mass of the mixture for each grinding is stipulated as 8g, and the mass ratio of iPP to UHMWPE is kept as 60 / 40, the content of the configured CNTs is respectively 1.34% (volume ratio, the same below, Example 1), 2.26% (Example 2), 2.73% (Example 3), 3.20% (Example 4), 3.68% % (Example 5), 4.65% (Example 6). First, weigh the mass of CNTs, iPP and UHMW...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com