Connecting structure for top blocks of molds

A connection structure and top block technology, which is applied in the field of plastic injection molding, can solve problems affecting production progress and production quality, loose long screws, mold damage, etc., to facilitate mass production and popularization and application, increase contact area, and not easy to loosen The effect of receding or breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a limitation to the present invention.

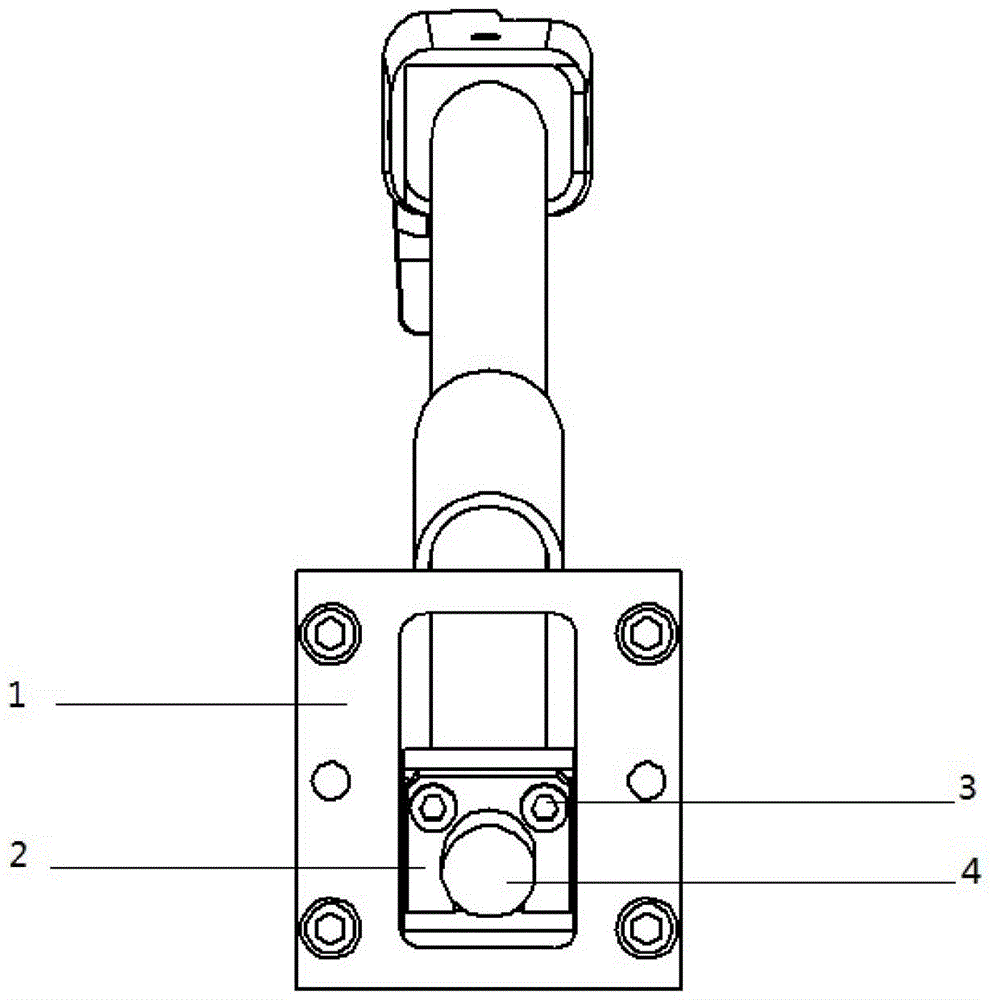

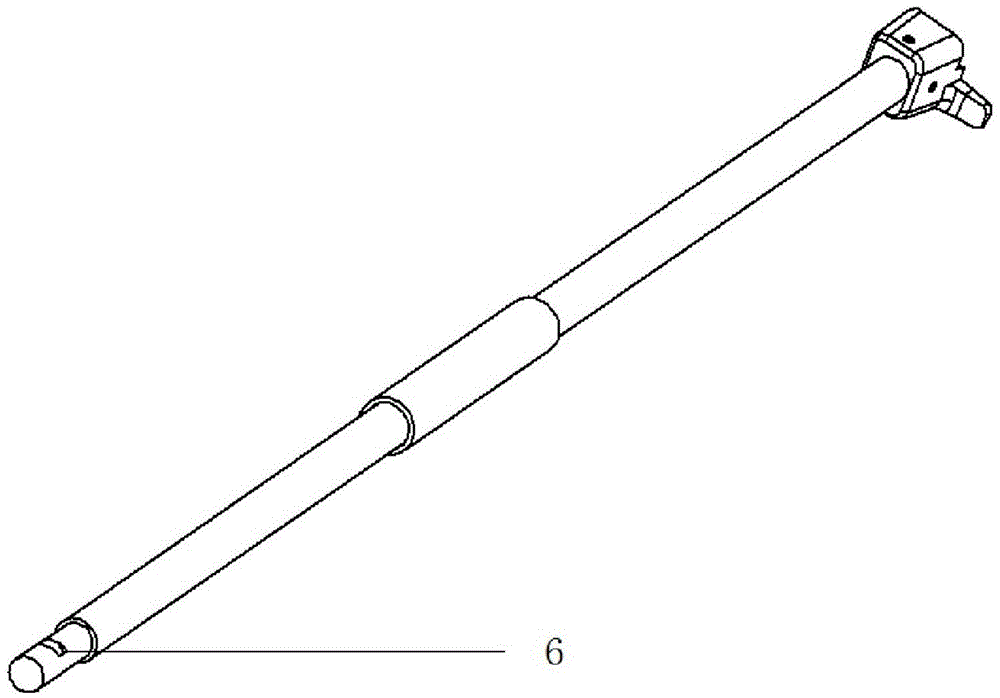

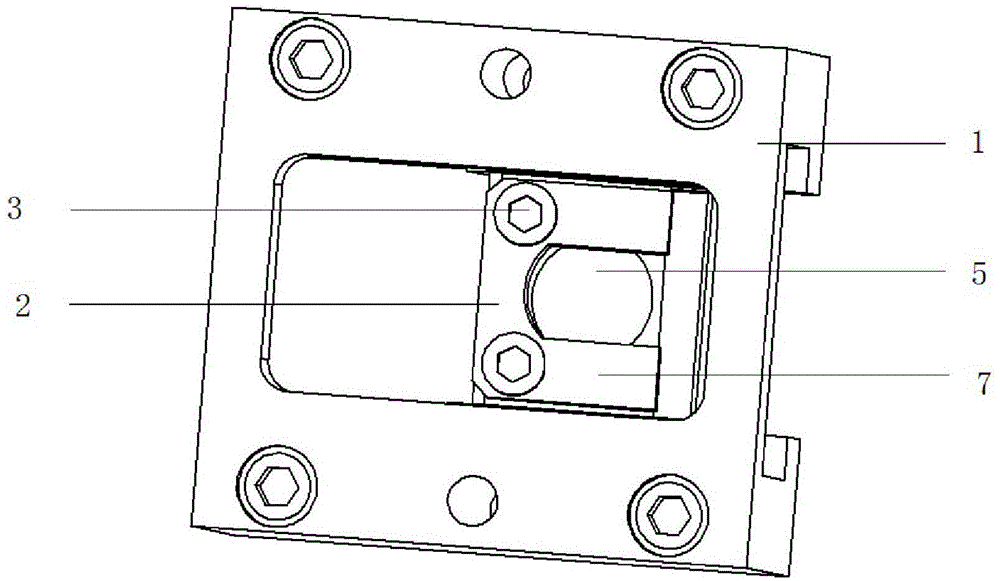

[0017] Such as figure 1 As shown, a mold top block connection structure includes a universal slide 1 and a cylindrical ejector pin 4 . Such as image 3 As shown, there is a positioning hole 5 on the universal slide 1, and the ejector rod 4 passes through the positioning hole 5. A mold jacking block connection structure further includes hexagon socket head cap screws 3 and U-shaped positioning blocks 2 , and the lower end of the ejector rod 4 passes through the universal sliding seat 1 . Such as figure 2 As shown, the lower end of the push rod 4 has a gap 6 along its circumference, the height of the gap 6 matches the thickness of the U-shaped positioning block 2, and the distance between the two support plates 7 of the U-shaped positioning block 2 is the same as the two gaps 6 on the push rod 4. The dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com