Xanthan gum-silver nanoparticle composite material and preparation method thereof

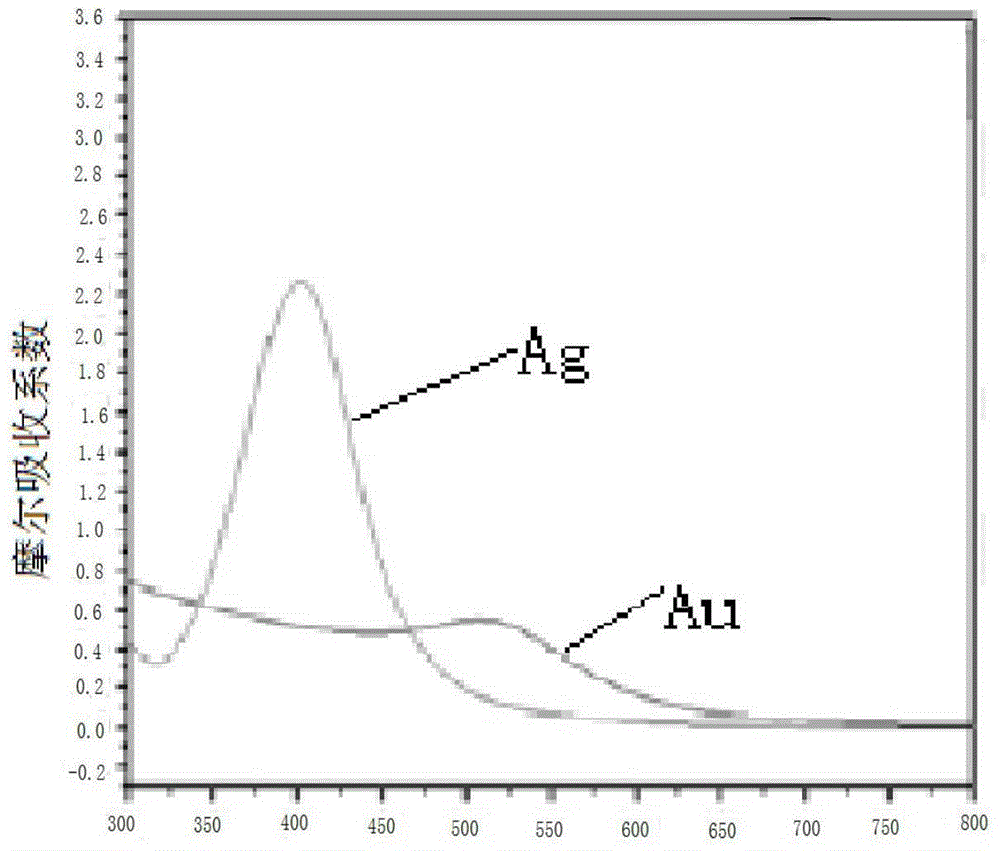

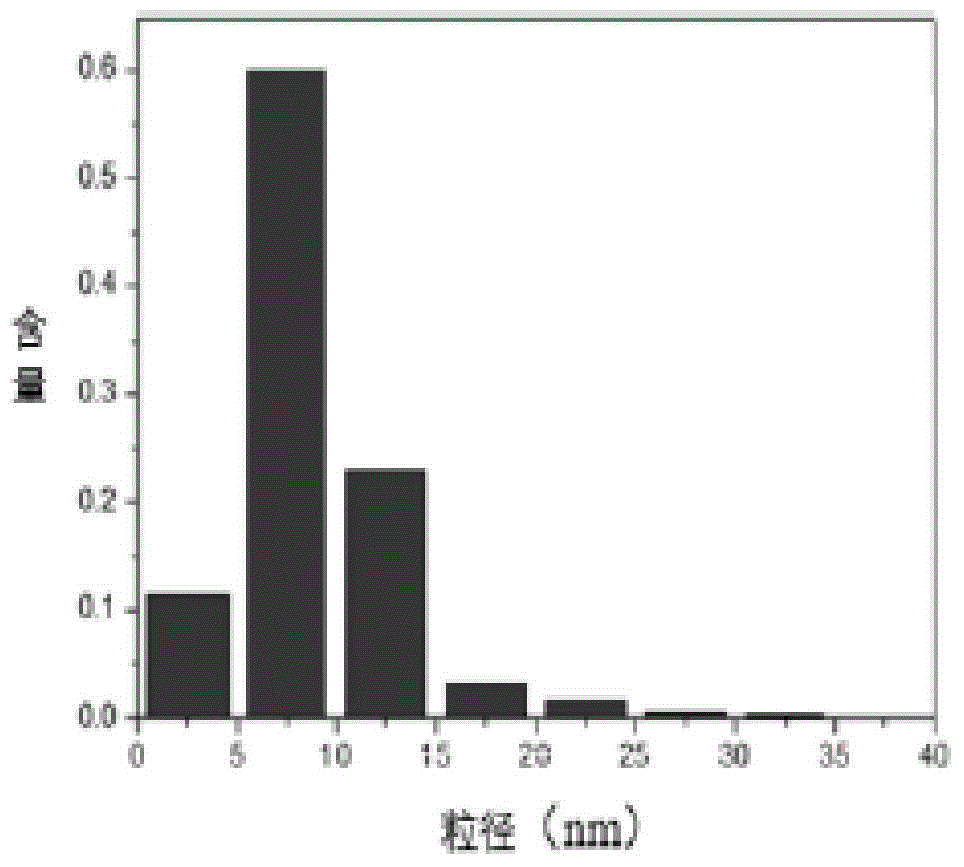

A composite material and a technology for xanthan gum, applied in the field of xanthan gum-silver nanocomposite materials and their preparation, can solve problems such as poor particle size uniformity of nano-silver, and achieve remarkable antibacterial effect, highly uniform size, and biocompatibility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The xanthan gum-silver nano-composite material of this embodiment is prepared by mixing xanthan gum solution and nano-silver sol, and the mixed solution is placed on a carrier and dried; xanthan gum and silver elements in the mixed solution The mass ratio is 4:9.

[0047] The preparation method of present embodiment xanthan gum-silver nanocomposite material, specific operation steps are as follows:

[0048] (1) Preparation raw materials:

[0049] A: Preparation of xanthan gum solution:

[0050]Weigh 5 mg of xanthan gum powder and dissolve it in 50 mL of deionized water. After magnetically stirring for 24 hours, centrifuge the solution for 2 hours, then place it in a water bath at 60°C for 6 hours, and cool to room temperature to obtain a 0.1 g / L xanthan gum solution. The 0.1g / L xanthan gum solution was diluted with deionized water to be 0.02g / L xanthan gum solution.

[0051] B: Preparation of nano-silver sol:

[0052] 1) 10mg HAuCl 4 Dissolve in 98mL deionized wate...

Embodiment 2

[0061] The xanthan gum-silver nano-composite material of this embodiment is prepared by mixing xanthan gum solution and nano-silver sol, and the mixed solution is placed on a carrier and dried; xanthan gum and silver elements in the mixed solution The mass ratio is 2:9.

[0062] The preparation method of present embodiment xanthan gum-silver nanocomposite material, specific operation steps are as follows:

[0063] (1) Preparation raw materials:

[0064] A: Preparation of xanthan gum solution:

[0065] Weigh 5 mg of xanthan gum powder and dissolve it in 50 mL of deionized water. After magnetically stirring for 24 hours, centrifuge the solution for 2 hours, then place it in a water bath at 60°C for 6 hours, and cool to room temperature to obtain a 0.1 g / L xanthan gum solution. The 0.1g / L xanthan gum solution was diluted with deionized water to be 0.02g / L xanthan gum solution.

[0066] B: Preparation of nano-silver sol:

[0067] 1) 10mg HAuCl 4 Dissolve in 98mL deionized wat...

Embodiment 3

[0074] The xanthan gum-silver nano-composite material of this embodiment is prepared by mixing xanthan gum solution and nano-silver sol, and the mixed solution is placed on a carrier and dried; xanthan gum and silver elements in the mixed solution The mass ratio is 1:9.

[0075] The preparation method of present embodiment xanthan gum-silver nanocomposite material, specific operation steps are as follows:

[0076] (1) Preparation raw materials:

[0077] A: Preparation of xanthan gum solution:

[0078] Weigh 5 mg of xanthan gum powder and dissolve it in 50 mL of deionized water. After magnetically stirring for 24 hours, centrifuge the solution for 2 hours, then place it in a water bath at 60°C for 6 hours, and cool to room temperature to obtain a 0.1 g / L xanthan gum solution. The 0.1g / L xanthan gum solution was diluted with deionized water to be 0.02g / L xanthan gum solution.

[0079] B: Preparation of nano-silver sol:

[0080] 1) 10mg HAuCl 4 Dissolve in 98mL deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com