A molding tool for a suspended grinding type ore crushing component and a manufacturing method thereof

A technology of ore crushing and production method, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of less use, the lack of guiding function of marking, and easy falling of cold iron, so as to reduce the risk of falling and liberate Design limitations, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

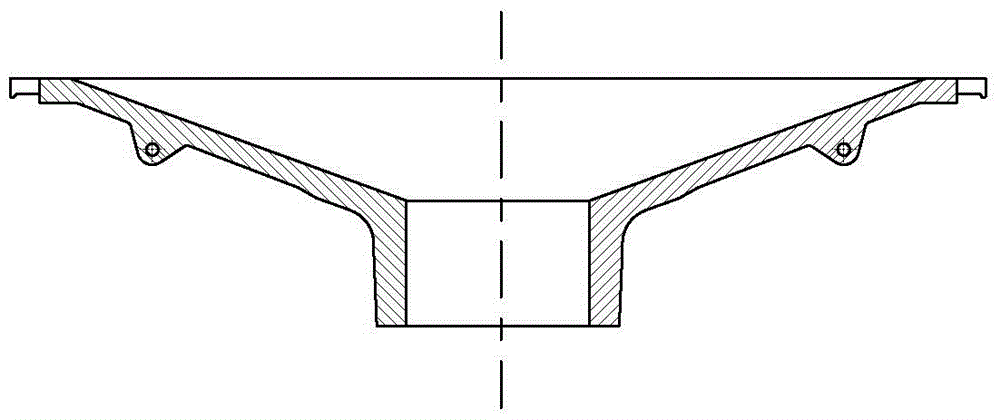

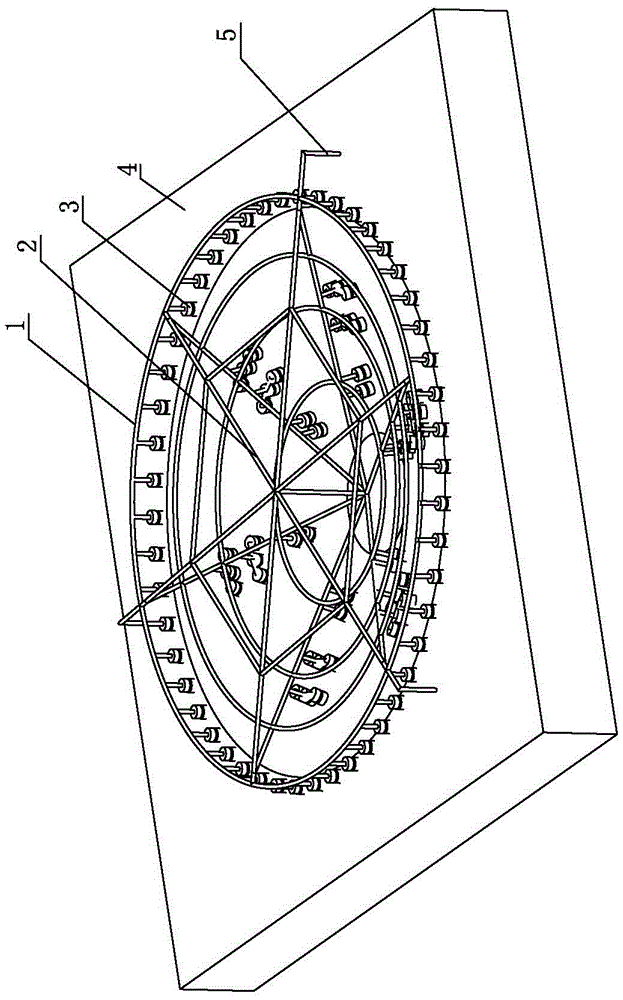

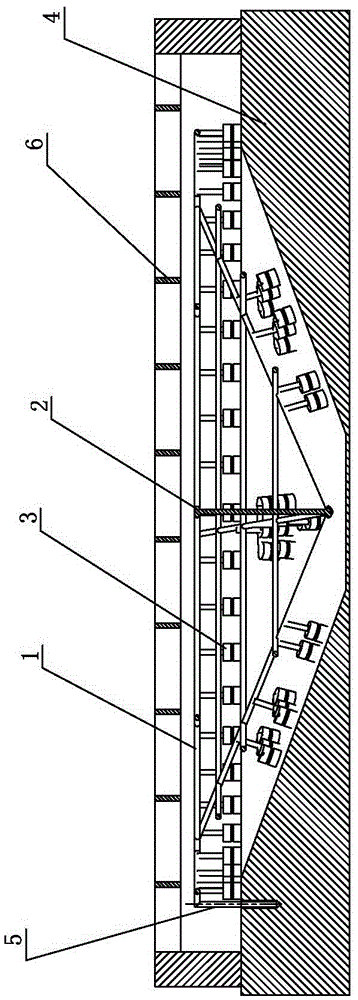

[0032] Such as figure 2 and image 3 Shown is the molding tooling of the suspension grinding type ore crushing part of the present invention, including a core upper pattern 4, a sand box 6 is placed on the core upper pattern 4, and a cold iron core bone assembly device is provided on the upper pattern 4. The cold iron The mandrel assembly device includes several concentric ring-shaped mandrels 1, and each ring-shaped mandrel 1 is distributed along the cone surface in order of diameter from small to large. On the opposite side of the annular mandrel 1 and the triangular truss 2 to the upper pattern 4 of the core, a number of cold irons 3 are fixed, and the outer periphery of the largest annular mandrel 1 is provided with a number of supporting positioning pins 5, and the corresponding positions of the upper pattern 4 of the core Several support holes corresponding to the support positioning pins 5 are provided. Wherein, the cold iron of the present invention includes direct-...

Embodiment 2

[0034] Adopt the manufacturing method of the modeling frock of the suspension grinding type ore crushing part of the present invention mainly through the following process system:

[0035] 1) According to the structural size of the suspension grinding type ore crushing part, the upper core pattern 4 is made, and the support hole matching the supporting positioning pin 5 is processed on the upper surface of the core upper pattern 4 according to the position of the supporting positioning pin 5 on the cold iron core bone assembly device ;

[0036] 2) To make the cold iron core bone combination device, first assemble and weld each annular core bone 1 and triangular truss 2 according to the design size, and then weld the supporting positioning pin 5 to make the core bone frame; The positioning holes are matched and installed so as to fix the core frame on the shape of the core; according to the design size and position, mark the fixed position of each cold iron on the core frame; w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com