Catalyst for synthesis of amino-terminated polyether

A technology of amino-terminated polyether and catalyst, which is applied in the field of catalysis, can solve the problems of low reaction conversion rate and high reaction pressure of synthesizing amino-terminated polyether, and achieve good catalytic effect, reduced reaction cost and high primary amine selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

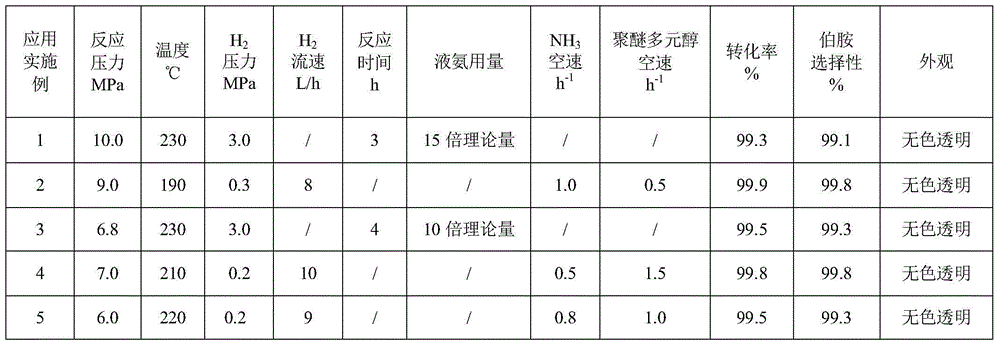

Examples

Embodiment 1

[0022] Take by weighing 56.7g nickel nitrate Ni (NO 3 ) 2 , 6.3g cobalt nitrate Co(NO 3 ) 2 , 0.34g chromium nitrate Cr(NO 3 ) 2 , 0.3g molybdenum nitrate Mo(NO 3 ) 2 (The mass ratio of Ni and Co is about 90:10, and the mass ratio of the main active material Ni, Co and auxiliary active material Cr and Mo is about 99:1) and 5g of carrier Al 2 o 3 (carrier and catalyst mass ratio about 20:80) is placed in 35ml deionized water, the mass concentration of metal salt solution is about 65%; Heating and stirring metal salt solution to 60 ℃, after 10min, add dropwise to it the mass fraction of 30% NaCO 3 The solution was 90ml, the dropping rate was 5ml / min, and after the addition was completed, it was aged at 60°C for 1h; after the aging was completed, it was suction-filtered, washed twice with deionized water and absolute ethanol, and then vacuum-dried at 100°C for 2h. Calcined at 500°C for 2 hours; after the calcination, the obtained catalyst was ground to 60 mesh and sieved...

Embodiment 2

[0024] Weigh 56.7g nickel nitrate Ni (NO 3 ) 2 , 6.3g cobalt nitrate Co(NO 3 ) 2 , 1.0g chromium nitrate Cr(NO 3 ) 2 , 2.3g molybdenum nitrate Mo(NO 3 ) 2 (The mass ratio of Ni and Co is about 90:10, and the mass ratio of the main active material Ni, Co and auxiliary active material Cr and Mo is about 95:5) and 5.4g of carrier Al 2 o 3 (The mass ratio of the carrier to the catalyst is about 20:80) placed in 33ml deionized water, the mass concentration of the metal salt solution is about 68%; heat and stir the metal salt solution to 70°C, and after 10min, dropwise add NaCO with a mass fraction of 35% 3 The solution was 85ml, the dropping rate was 4ml / min, and after the addition was completed, it was aged at 70°C for 1h; after the aging was completed, it was suction filtered, and washed twice with deionized water and absolute ethanol, and then vacuum-dried at 100°C for 2h, and then Calcined at 450°C for 2.5h; after the calcination, the obtained catalyst was ground to 60 ...

Embodiment 3

[0026] Weigh 56.4g nickel acetate Ni(CH 3 COO) 2 , 6.6g cobalt acetate Co(CH3 COO) 2 , 10.0g iron acetate Fe(CH 3 COO) 3 , 10.0g molybdenum acetate Mo(CH 3 COO) 2 (Ni, Co mass ratio 90:10, Ni, Co and Fe, Mo mass ratio 80:20), 6.9g carrier Al 2 o 3 and 4g of TiO 2 (Mass ratio of carrier to catalyst 25:75) was placed in 29.7ml deionized water, and a metal salt solution with a mass concentration of 70% was prepared; heated and stirred to 70°C, and after 20min, 40% NaCO was added dropwise 3 The solution is 80ml, the dropping rate is 3ml / min, after the end, it is aged at 80°C for 1h; it is suction filtered and washed 3 times with deionized water and absolute ethanol respectively, and then vacuum-dried at 100°C for 3h, and then calcined at 400°C for 4h ; After the calcination ends, the catalyst is ground to 30 mesh and sieved, and then with 20% H 2 / 80%N 2 The mixed gas was reduced at 160° C. for 1.5 h to obtain 35 g of black solid powder catalyst. The catalyst was sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com