Continuous evaporation and crystallization device and method capable of saving energy by mechanical steam recompression

An evaporative crystallization and mechanical steam technology, which is applied in the field of continuous evaporative crystallization devices, can solve the problems of increasing the complexity of the MVR system, unsatisfactory energy saving effect, and poor crystallization effect, and achieves the advantages of continuous crystallization, continuous production and reasonable structure. novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

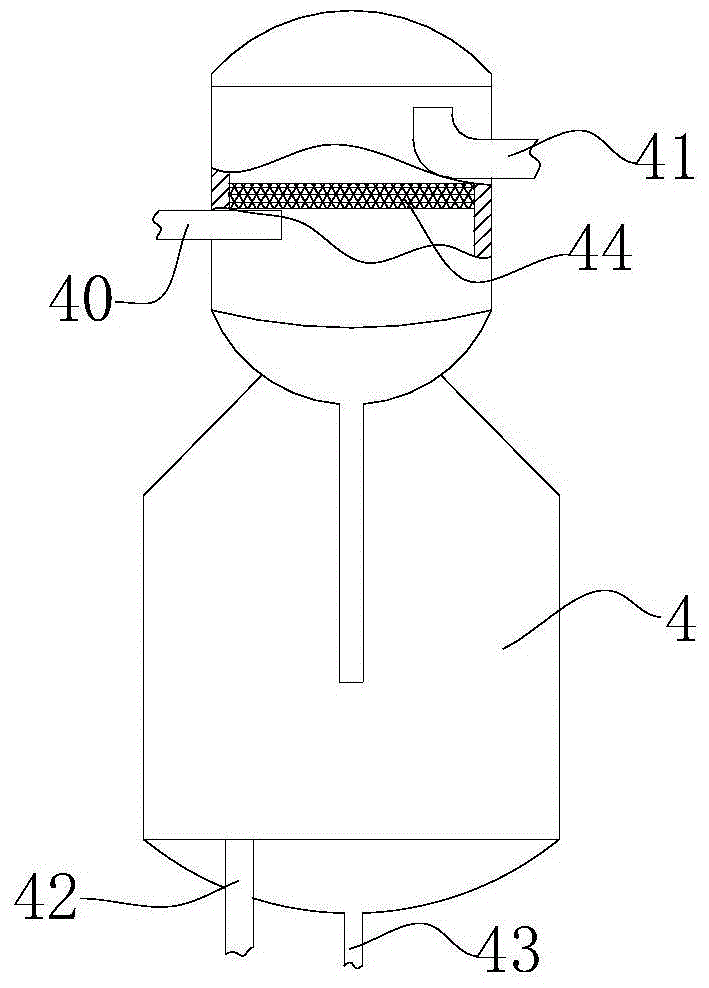

[0021] Such as figure 1 A continuous evaporative crystallization device with mechanical vapor recompression is shown. The evaporative crystallization device is mainly composed of a raw material tank 1, a preheater with an electric heater 2, a rising film evaporator 3, and a mechanical vapor Compressor 5, forced circulation evaporator 7, gas-liquid separator 4 and crystallization separator 6 are composed.

[0022] The above-mentioned preheater 2, rising film evaporator 3, and forced circulation evaporator 7 with electric heaters mainly heat the materials flowing into them by heat exchange. Therefore, the structure is a heat exchanger, and both have a supply for materials to flow in. The material input end, the material output end that flows through it and flows out to complete heating or evaporation; it also has a heat source input end that flows into the heat source and a cooling water output end, a total of four ports. In addition to the heat exchanger structure, the preheater 2...

Embodiment 2

[0041] The difference between Embodiment 2 and Embodiment 1 is that the mechanical vapor compressor 5 of this embodiment is a centrifugal compressor, and the rest repeats Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com