Feeding mechanism for medical needle base assembling

A needle seat and feeding technology, which is applied in the direction of devices introduced into the body, can solve problems such as difficult feeding catheters or venous needle assembly, to improve accuracy and feeding efficiency, improve accuracy and feeding efficiency, The effect of maintaining precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

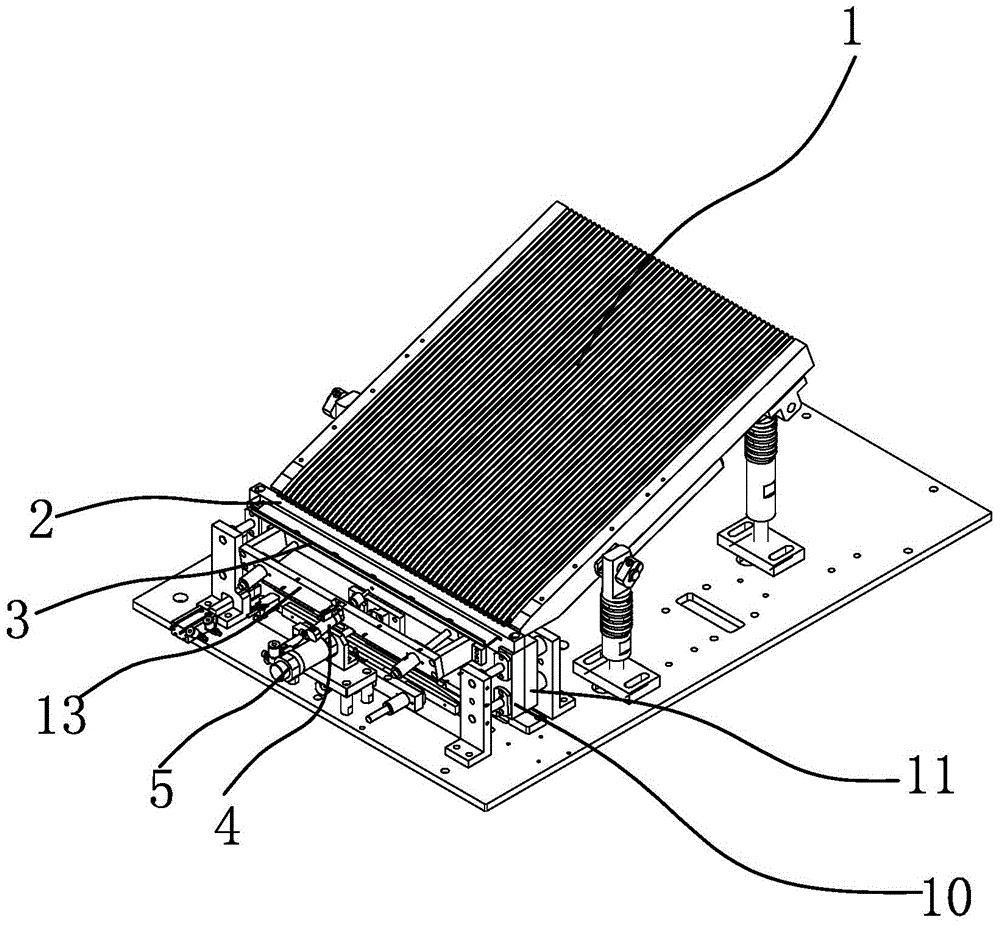

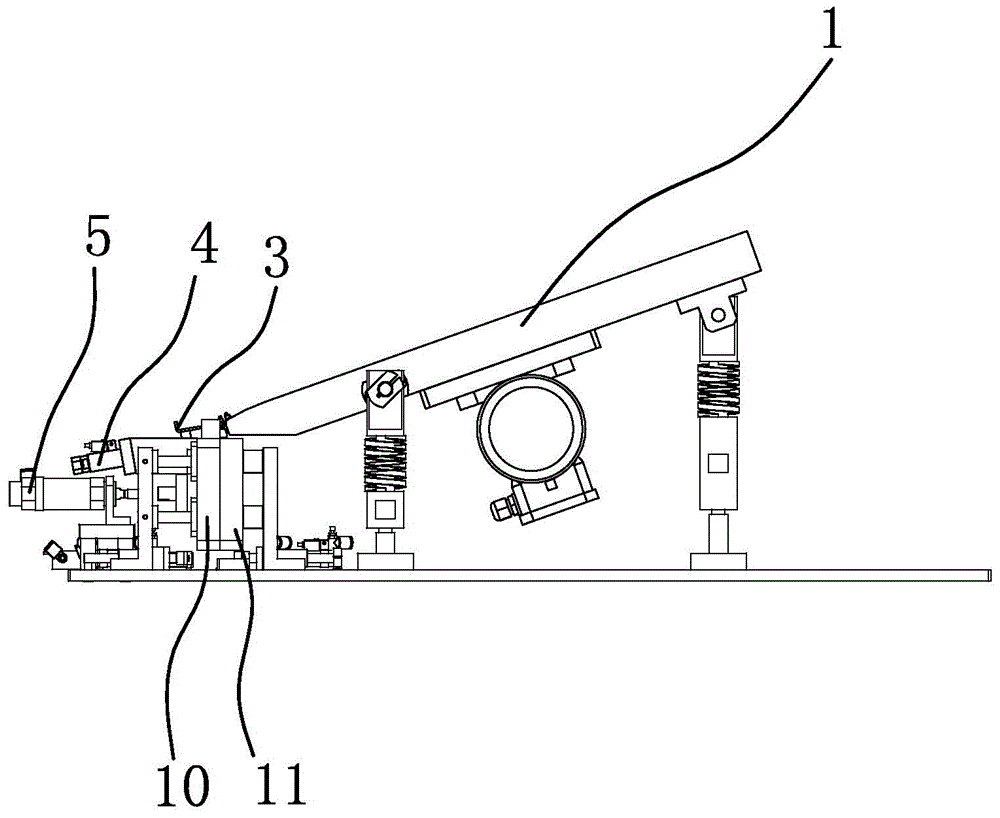

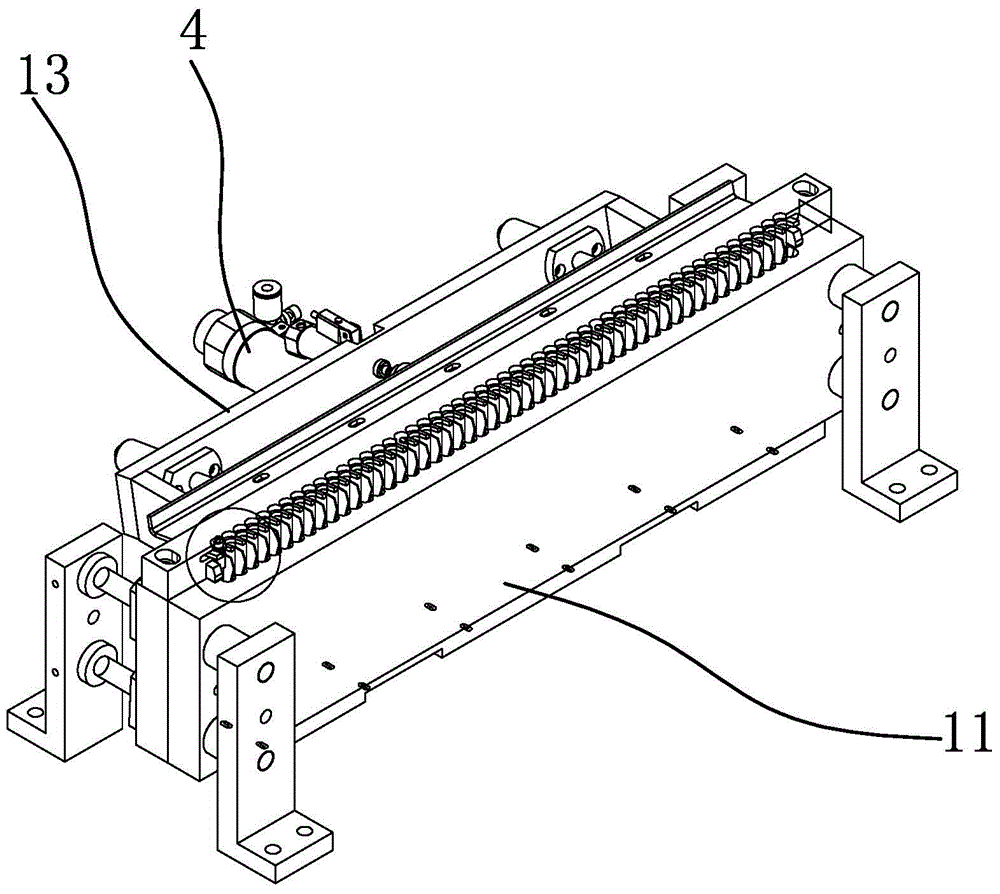

[0030] Such as Figure 1 to Figure 7 As shown, the feeding mechanism of the medical needle holder assembly includes a mounting seat 2 and a feeding track 1 capable of conveying the needle seat. The mounting seat 2 is provided with a through hole 21, and a hanging plate 3 is movably inserted into the through hole 21. The hanging plate 3 is connected with a driving part 4 that can drive the hanging plate 3 to move back and forth in the through hole 21. The rear end of the hanging plate 3 is fixedly connected to the driving part 4. The driving part 4 in this embodiment is adopted Cylinder 1, as a general case, a motor and a worm gear can be used instead. The front end of the hanging plate 3 can protrude out of the through hole 21 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com