Sugarcane cutting off device and sugarcane harvester

A cutting device and sugarcane technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as peeling, inability to generate time delays with the main cutter, and inability to cut sugarcane accurately, so as to achieve precise cutting blades, reduce Small peeling phenomenon, the effect of avoiding misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components or processes that are not relevant to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

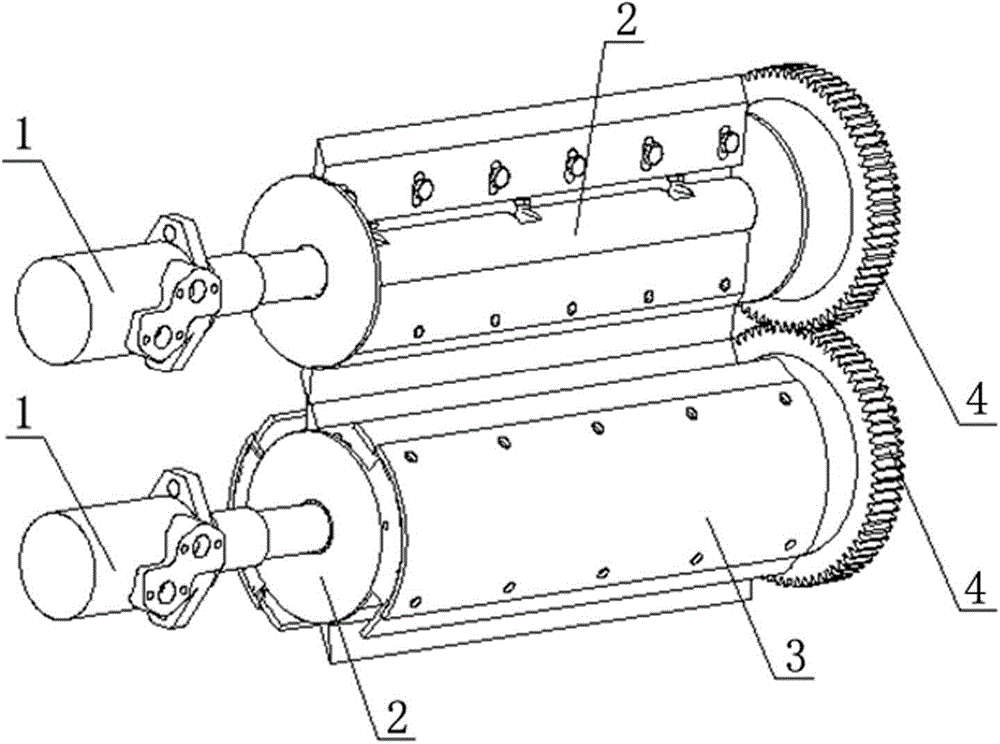

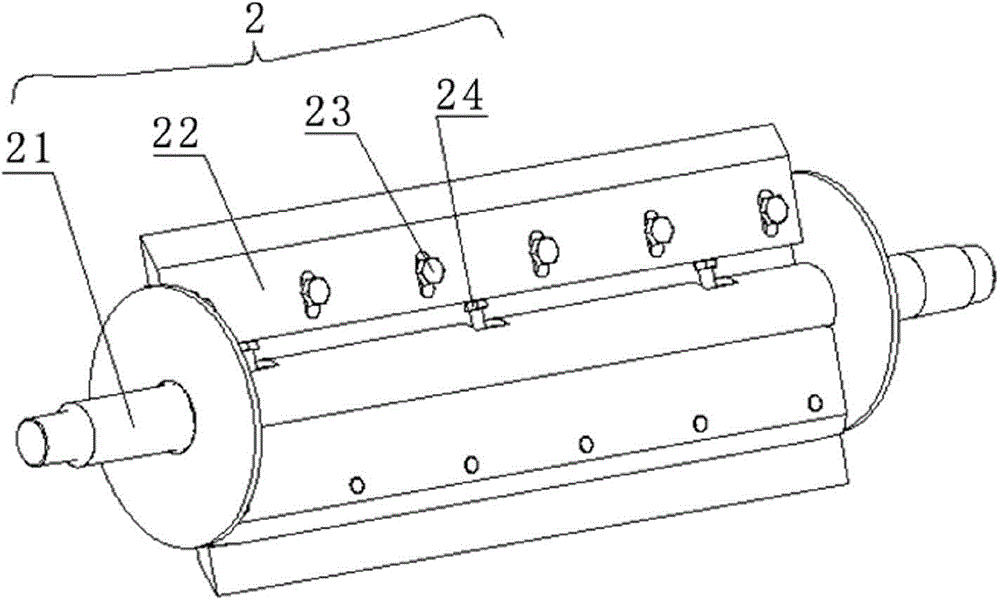

[0025] Such as figure 1 Shown, the present invention provided by the present invention proposes a kind of sugarcane cutting device, comprises two band cutting blades 22 respectively and cutting blades 22 can cut off the cutter cylinder 2 that can be arranged side by side when cutting off sugarcane relative, each cuts off the cutter cylinder 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com