X-ray inspection system

An inspection system and X-ray technology, applied in the field of X-ray applications, can solve the problems of affecting the monitoring effect, mechanical deformation interference, weak X-ray beam intensity, etc., and achieve accurate and reliable monitoring results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

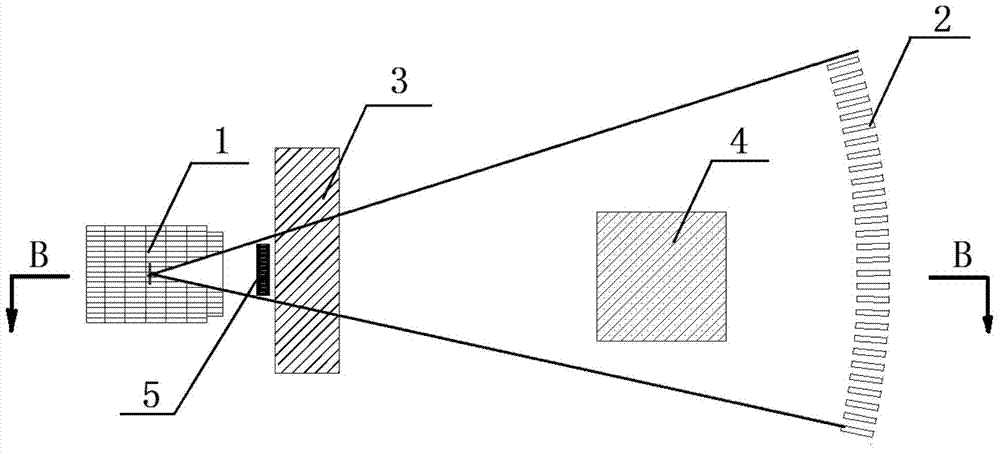

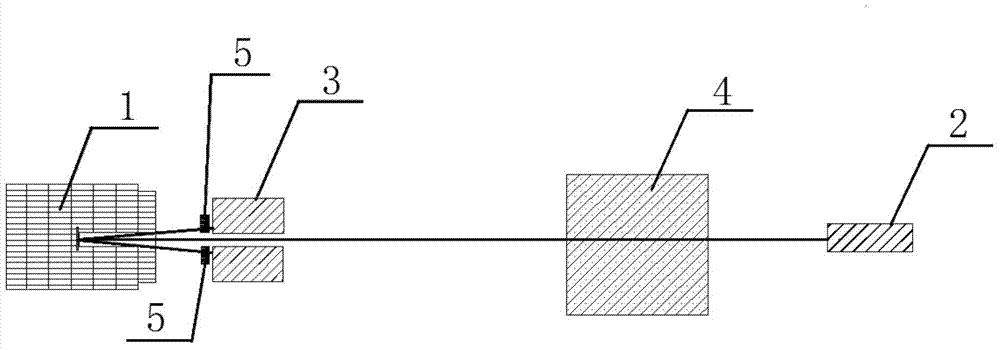

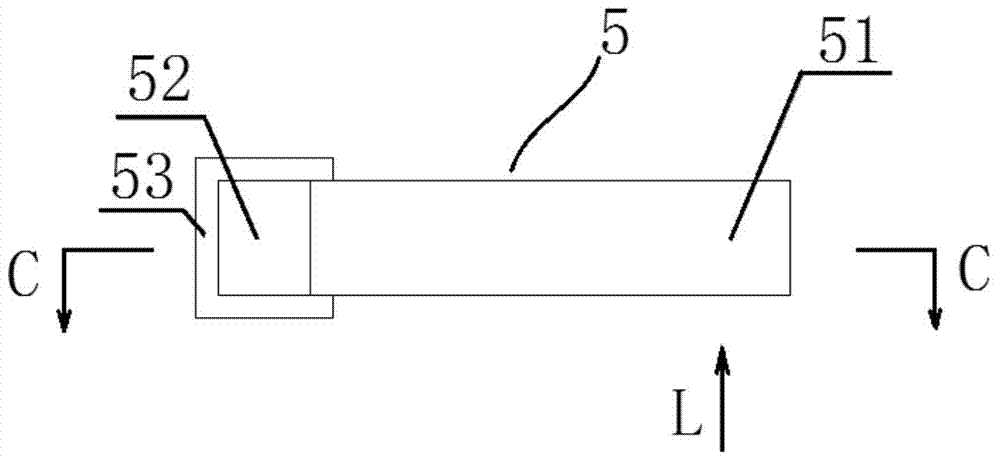

[0049] Figure 1 to Figure 5 An X-ray inspection system of a first embodiment of the present invention is shown.

[0050] figure 1 It is a schematic layout diagram of the X-ray inspection system according to the first embodiment of the present invention. figure 2 for figure 1 The BB-direction sectional schematic diagram of the X-ray inspection system shown. Such as figure 1 and figure 2 As shown, the X-ray inspection system of the first embodiment includes an X-ray emitting device for emitting X-rays, a collimator 3, a detector array 2 for X-ray inspection, and an X-ray beam intensity monitoring device. Wherein the X-ray beam intensity monitoring device is used for monitoring the X-ray beam intensity of the X-ray emitting device.

[0051] The X-ray beams emitted by the X-ray emitting device include working beams irradiated on the detector array 2 and redundant beams irradiated outside the detector array 2 .

[0052] In the first embodiment, the X-ray emitting device i...

no. 2 example

[0074] The difference between the second embodiment and the first embodiment is that in the second embodiment, the gas detection module 6 replaces the scintillation detection module 5 of the first embodiment as the intensity detection module. Wherein, the left detection module and the right detection module each use a gas detection module 6 with the same structure to detect the intensity of the X-ray beam.

[0075] Figure 6 It is a schematic diagram of the structural principle of the intensity detection module of the X-ray beam intensity monitoring device in the X-ray inspection system according to the second embodiment of the present invention. Figure 7 for Figure 6 The schematic diagram of the structural principle of the intensity detection module when it is perpendicular to the X-ray fan-shaped beam is shown. Figure 6 and Figure 7 The working principle of the intensity detection module of the second embodiment will be described by taking one of the left detection mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com