Light source module, fabrication method therefor, and backlight unit including the same

A light source module and backlight unit technology, which is applied in the direction of light source, electric light source, optical components, etc., can solve the problems of thinness limitation of backlight unit, degradation of LED package efficiency, etc., and achieve the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

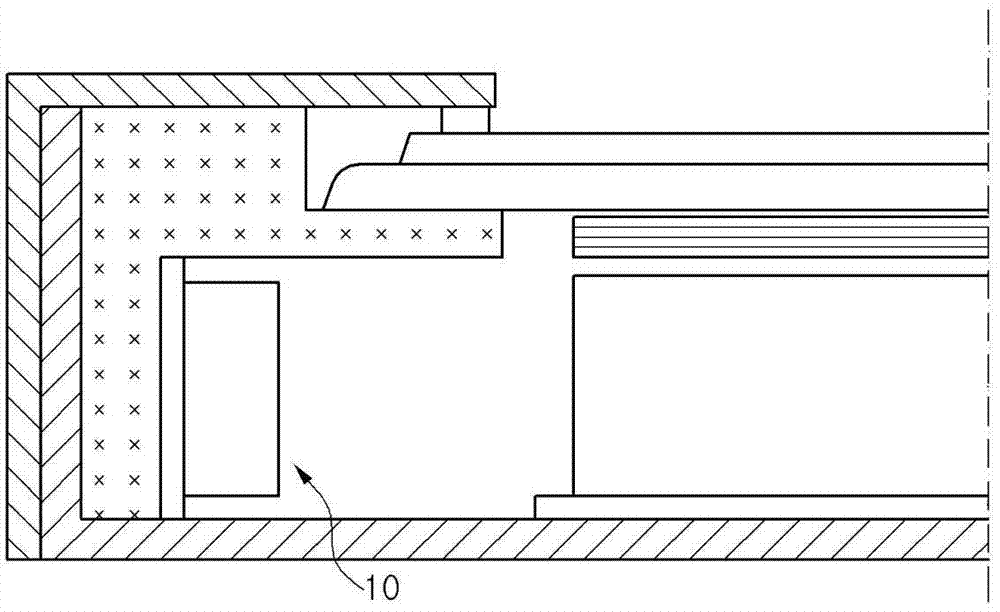

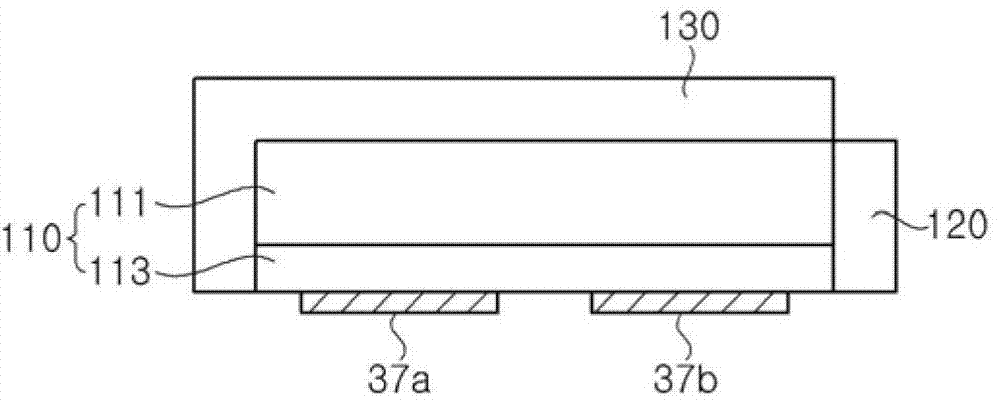

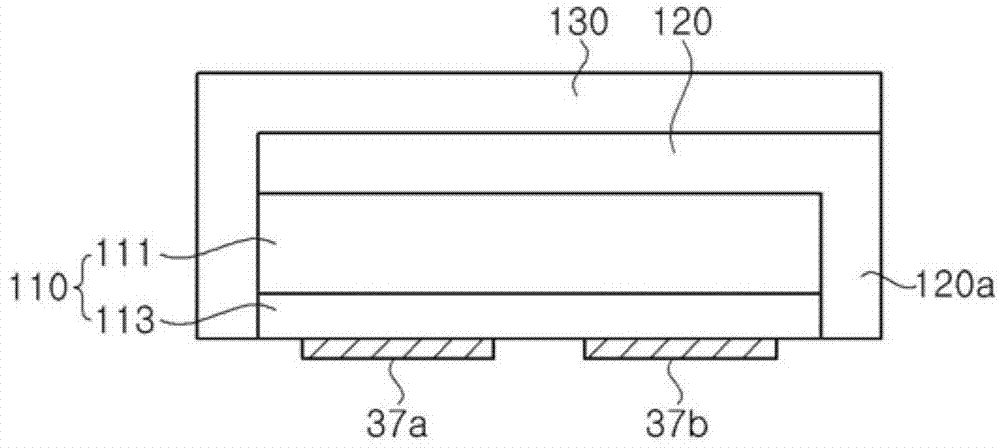

[0044] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. The following embodiments are provided by way of examples to fully convey the spirit of the present invention to those skilled in the art. Therefore, the present invention is not limited to the embodiments disclosed herein, but can also be implemented in different forms. In addition, the shapes of elements in the drawings may be exaggerated. Throughout the specification, the same reference signs indicate the same elements having the same or similar functions. Modifications of elements falling within the spirit and scope of the present invention do not include a restrictive meaning, but are provided to clearly express the spirit of the present invention, and can only be limited by the claims.

[0045] Hereinafter, the embodiments of the present invention will be specifically described with reference to the accompanying drawings, so that thos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com