Automatic proportioning conveying device

A conveying device and automatic proportioning technology, which is applied in the direction of supply device, clay preparation device, mixing operation control device, etc., can solve the problems of increasing construction costs and high requirements for pouring equipment, so as to reduce input costs, facilitate adjustments, and enhance The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

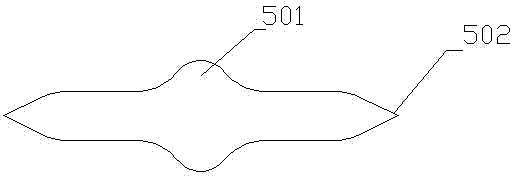

[0020] As shown in the figure, an automatic proportioning conveying device includes a conveying pipe 1 made of a composite wear-resistant pipe, a motor 2 connected to one end of the conveying pipe 1, and a gantry 3 supporting the motor 2, wherein the motor 2 Explosion-proof motor is adopted, fixedly arranged on the crossbeam above the gantry 3, the soft auger 5 is arranged in the delivery pipe 1, one end of the soft auger 5 is connected with the motor through the transmission shaft 4, and is transported on the side of the transmission shaft 5 A discharge port 6 is arranged on the pipe wall of the tube 1, and the other end of the soft auger 5 is a free end. The soft auger 5 is composed of spiral blades, and a prominent stirring ridge 501 is set along the spiral direction in the middle of both sides of the surface of the spiral blade. And be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com