Full-automatic drilling-riveting machine tool

A fully automatic, machine tool technology, applied to boring machine/drilling machine components, maintenance and safety accessories, drilling/drilling equipment, etc., to achieve the effect of reasonable circuit design, convenient wiring, and easy installation and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

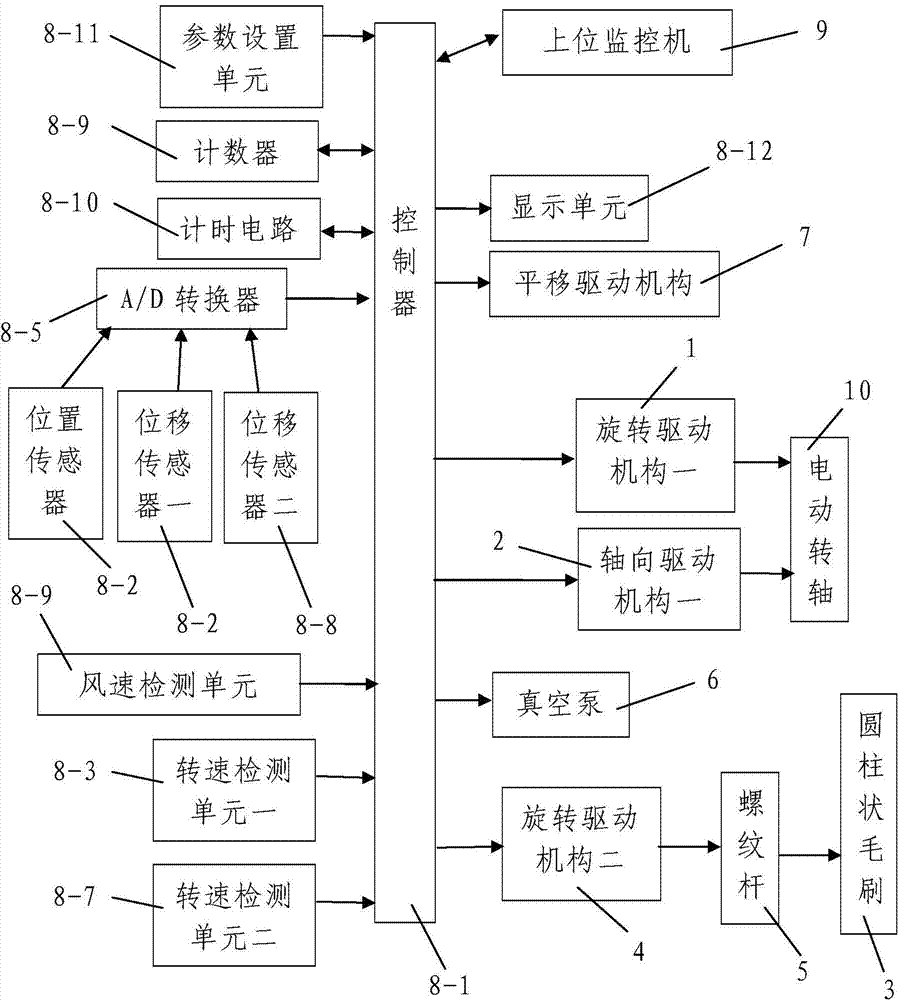

[0026] Such as figure 1 As shown, the present invention includes a machine tool body, a control system arranged on the machine tool body, and a drilling device, a riveting device and an automatic metal chip cleaning device installed on the machine tool body, the drilling device, the metal scrap The chip automatic cleaning device and the riveting device are arranged from front to back and the three are arranged on the same horizontal plane. The machine tool body is provided with a workpiece clamping mechanism for clamping the workpiece to be processed and for the workpiece clamping mechanism to perform The moving track that moves back and forth, the workpiece clamping mechanism is driven by the translation drive mechanism 7 and is connected to the translation drive mechanism 7 through a transmission mechanism. The drilling device includes a drill bit, an electric rotating shaft 10 installed on the drill machine body and driving the drill bit to continuously rotate, a rotary dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com