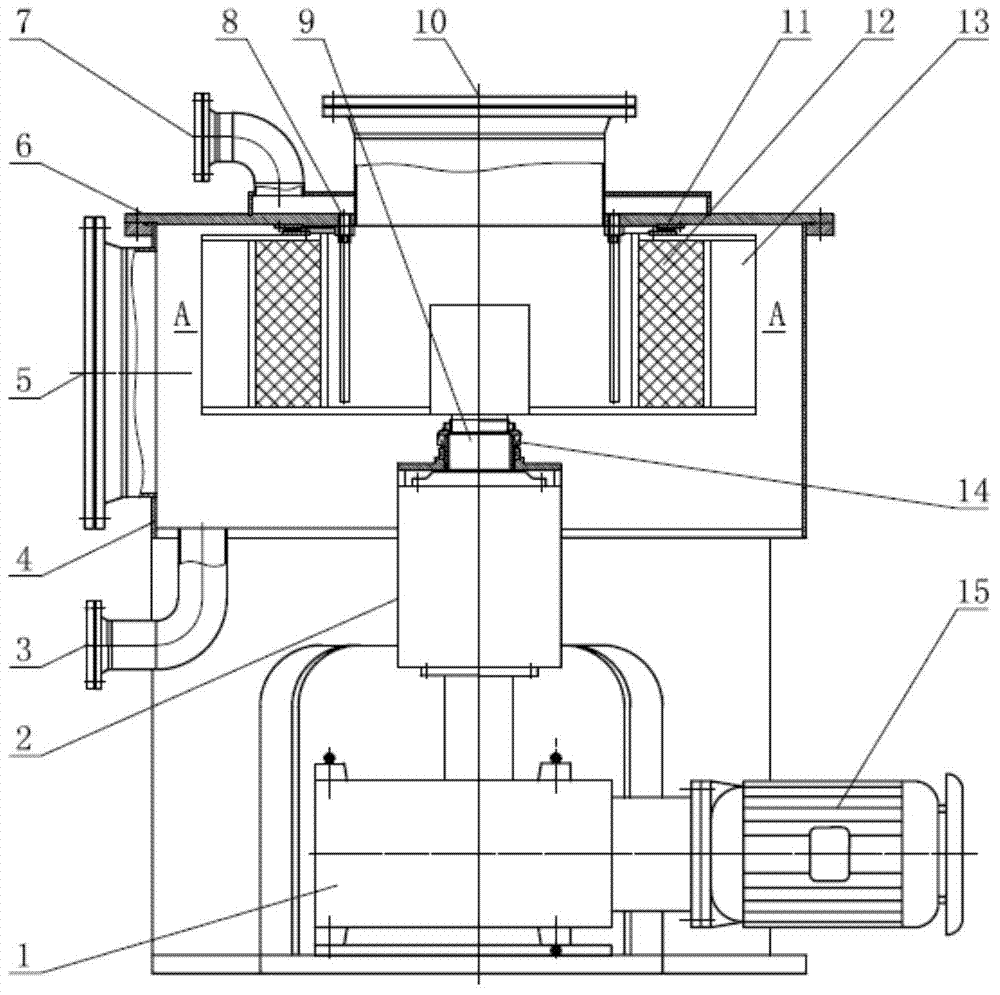

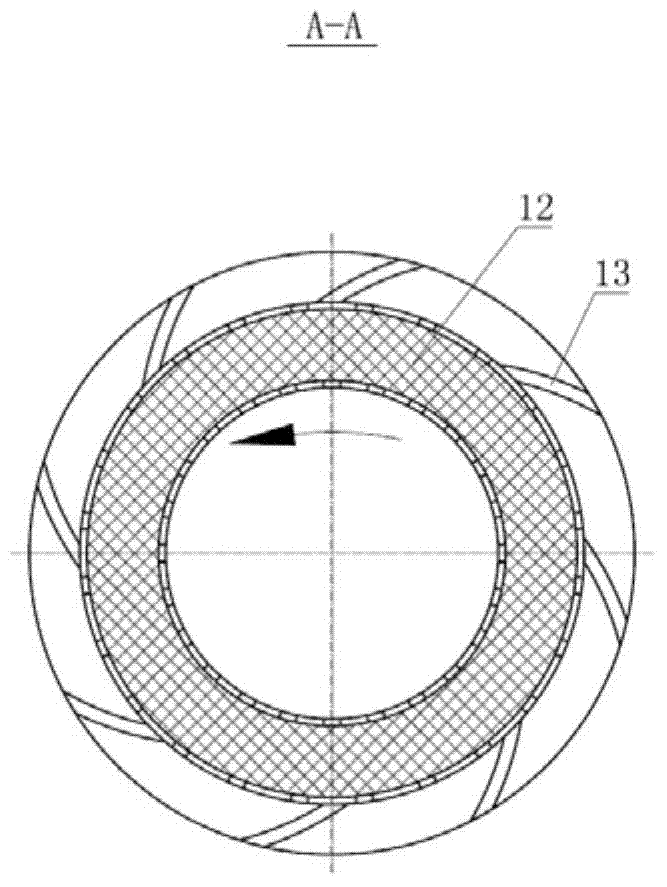

Self-pressurized rotation filling bed apparatus with whole structured filler, and applications thereof

A technology of rotating packed bed and structured packing, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve the problems of large gas pressure drop, easy fracture, and low mass transfer performance. The effect of small floor area and large operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

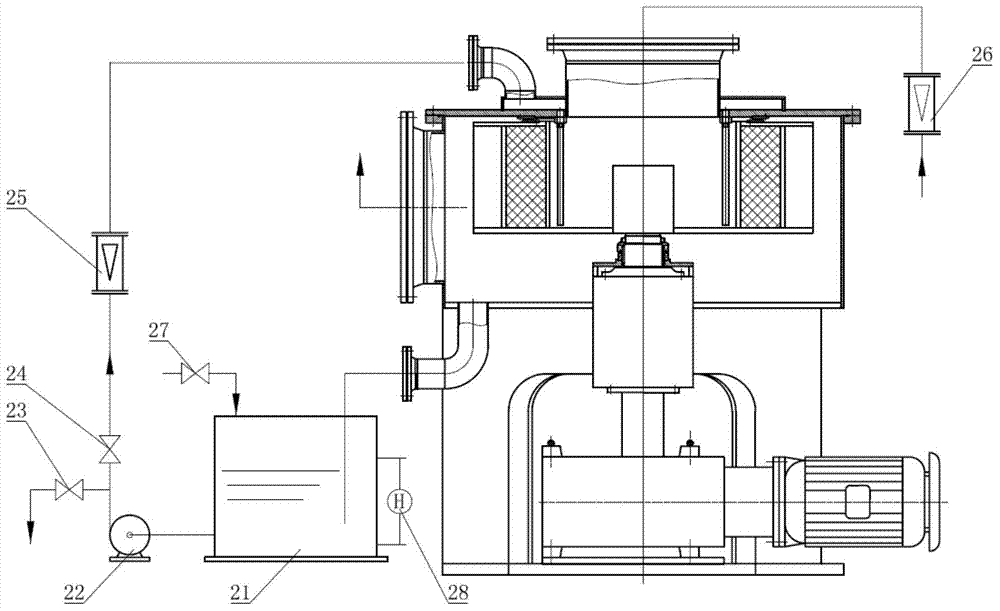

[0051] A method for deep removal of harmful gases in ship exhaust by using the above-mentioned self-pressurized rotating packed bed device with integral structured packing, the conditions are as follows:

[0052] Sulfur dioxide content in imported gas φ i 2590mg / m 3 , the absorption liquid is ammonium sulfite-ammonium bisulfite mixed solution. The system temperature T in the absorption process was 50°C. SiC filler is used in the rotating packed bed, the rotational speed N of the rotating packed bed is 500r / min, and the gas-liquid flow ratio η is 800. The content of sulfur dioxide in the outlet gas of the rotating packed bed φ o 80mg / m 3 , The inlet and outlet pressure drop Δp is -600Pa.

Embodiment 2-15

[0054] The process flow and steps are the same as in Example 1, and the process conditions and operating conditions of each embodiment and the corresponding experimental results are shown in Table 1.

[0055]

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com