SiC molded body and method for producing SiC molded body

A manufacturing method and molding technology, applied in chemical instruments and methods, gaseous chemical plating, inorganic chemistry, etc., can solve the problems of low resistivity and low light transmittance, which have not yet been obtained, and achieve high resistivity and light transmittance Sexually low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

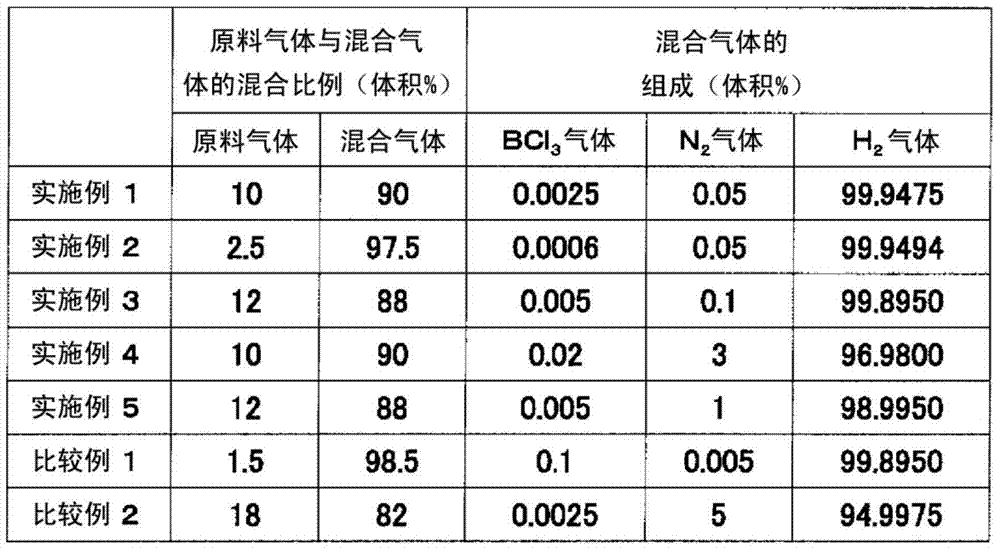

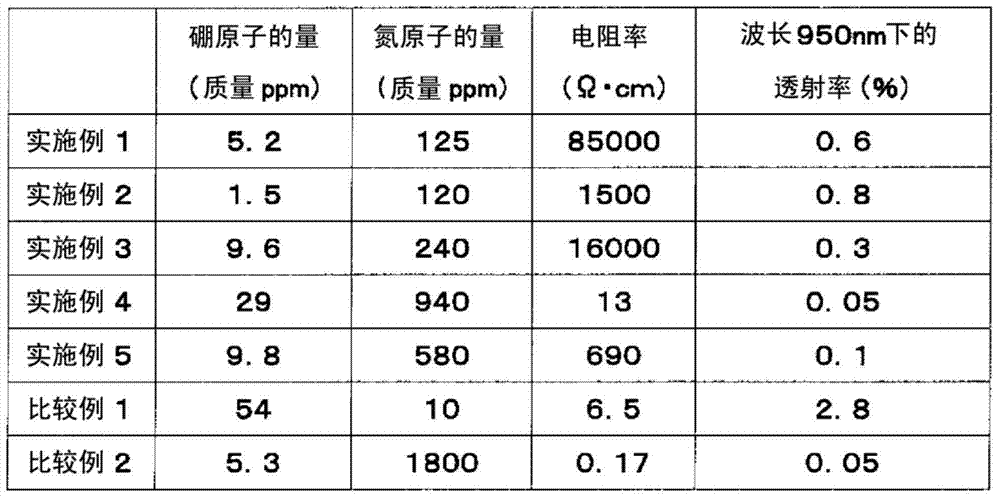

Embodiment 1

[0091] (1) As a reaction vessel in which a 200 L reaction chamber is provided inside, a reaction vessel is used: a high-frequency coil for heating the reaction chamber is arranged on the outside, and a raw material gas introduction pipe for introducing a raw material gas into the reaction chamber is provided. A mixed gas introduction pipe for introducing a mixed gas of a boron compound gas, a nitrogen atom-containing compound gas, and a carrier gas, and an exhaust port for exhausting the reaction chamber. In the above-mentioned reaction chamber, a disk-shaped graphite substrate with a diameter of 200 mm and a thickness of 5 mm (impurity content of 16 mass ppm, thermal expansion coefficient of 4.2×10 -6 / °C, bulk density is 1.79).

[0092] (2) As a raw material gas, CH 3 SiCl 3 The gas is introduced into the reaction chamber from the raw material gas introduction pipe, and BCl is used as the boron compound gas 3 Gas, N is used as nitrogen atom-containing compound gas 2 Gas,...

Embodiment 2

[0100] In Example 1, as the mixed gas, BCl was used in a volume ratio at a temperature of 20°C 3 Amount of gas relative to BCl 3 Gas, N 2 Gas and H 2 The total amount of gas reaches 0.0006 vol%, N 2 Amount of gas relative to BCl 3 Gas, N 2 Gas and H 2 The total amount of gas reaches 0.05% by volume, H 2 The amount of gas relative to the above BCl 3 Gas, N 2 Gas and H 2 The gas that was mixed so that the total amount of the gas was 99.9494% by volume, and the raw material gas (CH 3 SiCl 3 The introduction amount of gas) is relative to CH 3 SiCl 3 Gas, BCl 3 Gas, N 2 Gas and H 2 The total amount of gas is 2.5% by volume, and the introduction amount of the mixed gas is relative to the above CH 3 SiCl 3 Gas, BCl 3 Gas, N 2 Gas and H 2 Except that the raw material gas and the mixed gas were simultaneously introduced so that the total amount of gas would be 97.5% by volume, it was carried out in the same manner as in Example 1 to obtain a disk-shaped SiC compact ...

Embodiment 3

[0103] In Example 1, as the mixed gas, BCl was used in a volume ratio at a temperature of 20°C 3 Amount of gas relative to BCl 3 Gas, N 2 Gas and H 2 The total amount of gas reaches 0.005 vol%, N 2 Amount of gas relative to BCl 3 Gas, N 2 Gas and H 2 The total amount of gas reaches 0.1 vol%, H 2 The amount of gas relative to the above BCl 3 Gas, N 2 Gas and H 2 The gas that was mixed so that the total amount of the gas would be 99.8950% by volume, and the raw material gas (CH 3 SiCl 3 The introduction amount of gas) is relative to CH 3 SiCl 3 Gas, BCl 3 Gas, N 2 Gas and H 2 The total amount of gas is 12% by volume, and the introduction amount of the mixed gas is relative to the above CH 3 SiCl 3 Gas, BCl 3 Gas, N 2 Gas and H 2 Except that the raw material gas and the mixed gas were simultaneously introduced so that the total amount of gas became 88% by volume, it was carried out in the same manner as in Example 1 to obtain a disk-shaped SiC compact with a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com