Tunable materials

A technology for graphite materials, plastics, used in anti-corrosion coatings, nanotechnology for materials and surface science, fibrous fillers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

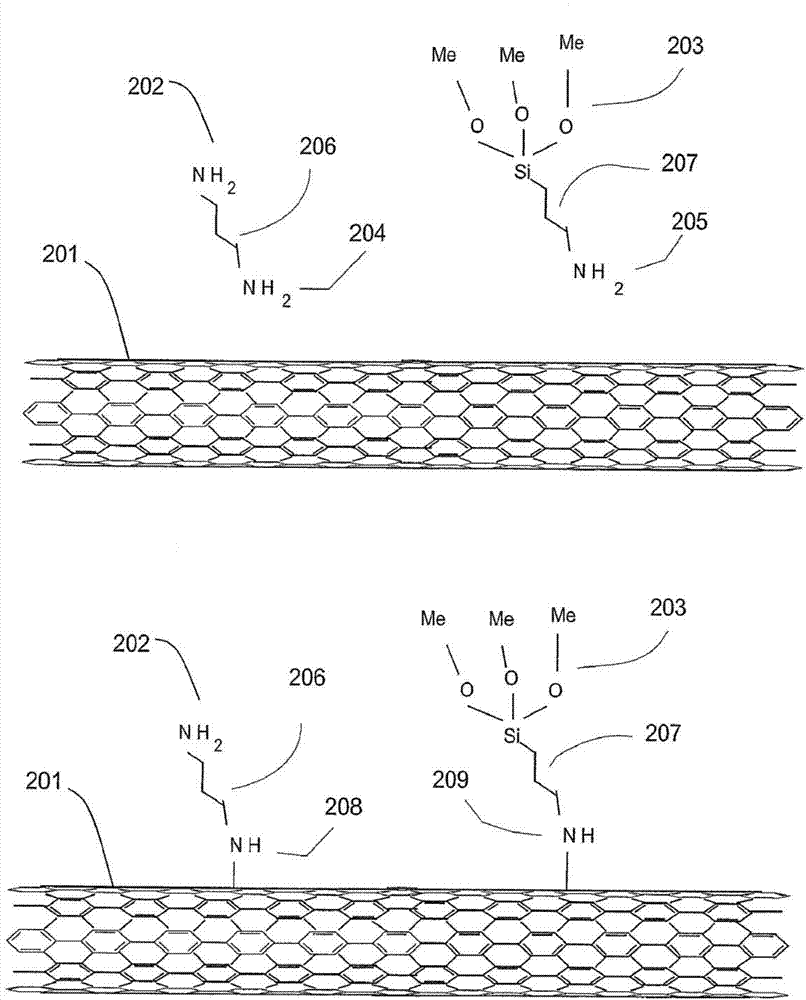

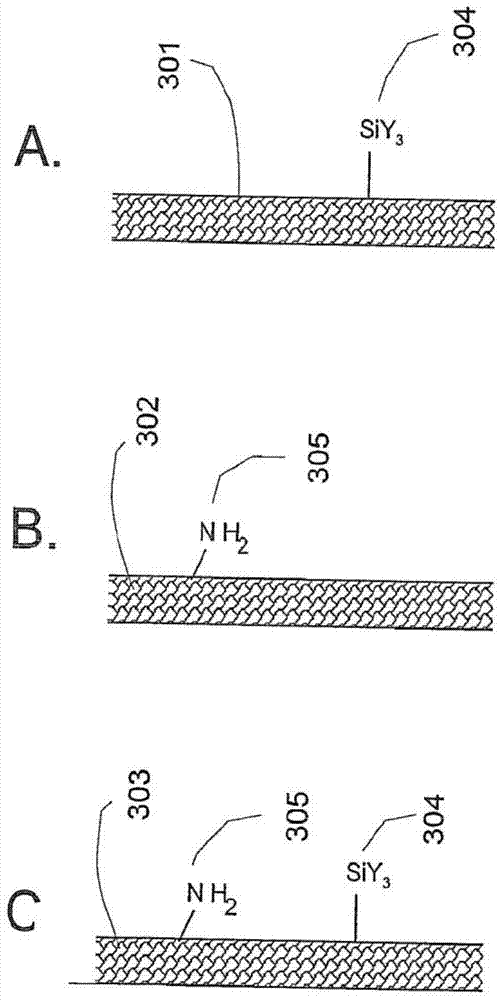

[0086] Multilayer CNTs (10 g, Baytubes, Bayer, Germany) and 10 g of aminopropyltrimethoxysilane were sonicated in 1000 g of Jeffamine ED-900 hardener (Huntsman, USA) using 1 g of aluminum tripropoxide as a catalyst. The power is 800W and the time is about 10min. This hardener (designated HNT-hardener) is ready to be used with a bisphenol A epoxy resin comprising 80 ml of dimethyldimethoxysilane and 20 g of diphenyldimethoxysilane.

Embodiment 2

[0088] Multilayer CNT (10g, Baytubes, Bayer, Germany), nanoparticles of 5g silica and 5g alumina, and 10g aminopropyltrimethoxysilane were mixed in a mortar and mortar in 100ml Jeffamine ED-900 hardener (Huntsman, USA). Medium grinding for about 30min. The hardener was diluted to 1000g using anhydrous Jeffamine HK-511 (expressed as HNT-NP-hardener), prepared with 1450g bisphenol containing 80ml dimethyldimethoxysilane and 20g diphenyldimethoxysilane A epoxy resin is used together.

Embodiment 3

[0090] The material from Example 2 was diluted with 200 ml isopropanol, filtered and washed with 100 ml isopropanol. The solid was dried under vacuum. The functionalized CNTs were dispersed in 1000ml of 3,3'-dimethyl-4,4'-diaminodicyclohexylmethane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com