High-efficiency energy-saving electric motor with internal shielding ventilation opening

A high-efficiency, energy-saving, venting technology, applied in the direction of electric components, cooling/ventilation devices, electrical components, etc., can solve the problem of not allowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

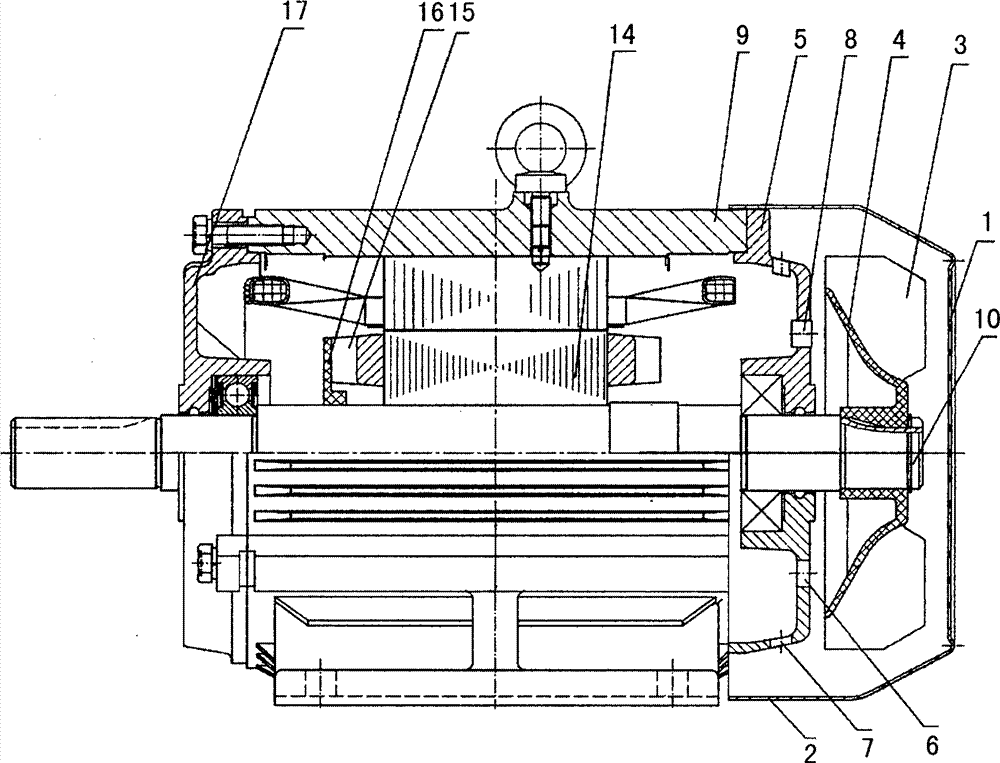

[0017] image 3 In order to realize the rapid circulation of air inside the motor, referring to the structure of the patented technology "High-efficiency Energy-saving Motor with Forced Internal Circulation Heat Dissipation", the centrifugal exhaust fan structure at one end of the rotor (actually the windshield) and the steering are arranged on the shaft of the motor. Extend the end, replace the external fan structure with the "forced air cooling system of the whole motor" in the cost technology.

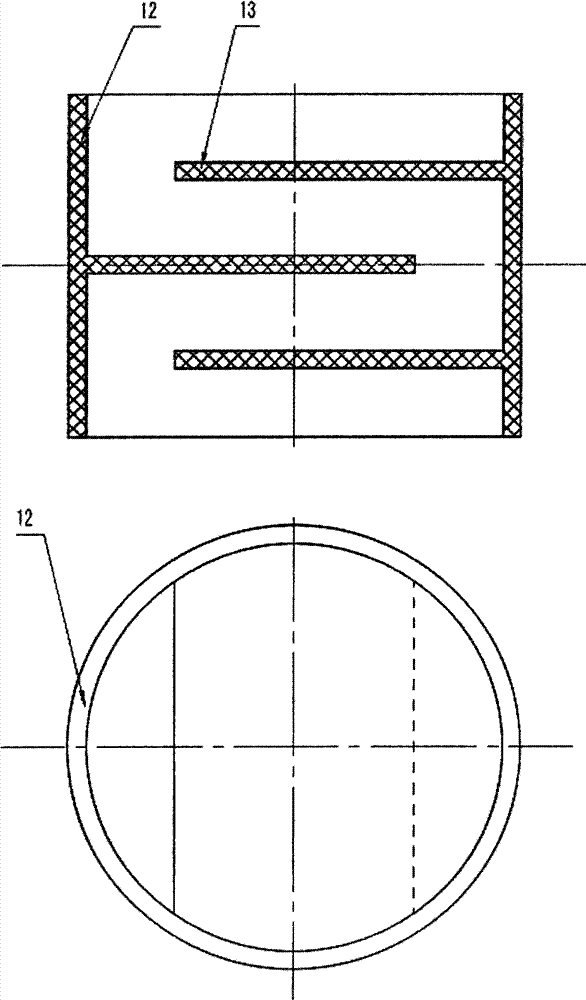

[0018] The simple description is: add a windshield to the top of the fan teeth at the shaft extension end of the motor rotor to form a rotor with a centrifugal exhaust fan, process a vent on the rear end cover, embed the inner shielding component, and match the ordinary outer fan and wind cover. The result is a complete energy efficient motor with inner shielded vents.

[0019] Whether the rotor core has ventilation holes, and whether the rear end cover ventilation holes are embedd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com