Coreless coil and motor with same

A hollow cup and coil technology, which is applied in the shape/style/structure of the winding conductor, can solve the problems of inconsistent circulating current and inability to solve the amplitude of the back EMF, and achieves the advantages of reducing operating loss, being easy to implement, and reducing operating temperature rise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution in the embodiment of the present invention will be clearly and completely described below, obviously, the described embodiment is a module embodiment of the present invention, not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts shall fall within the protection scope of the present invention.

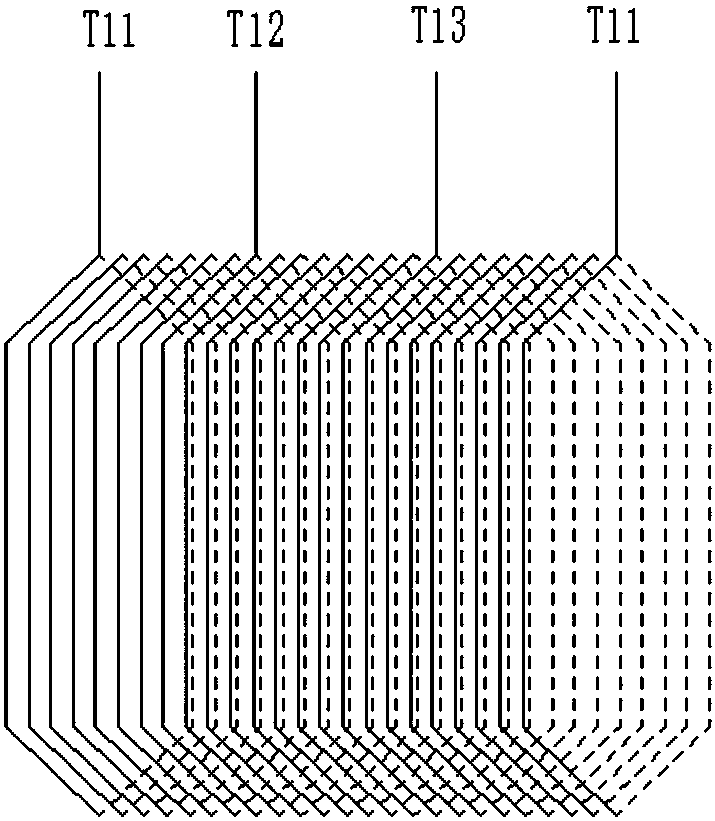

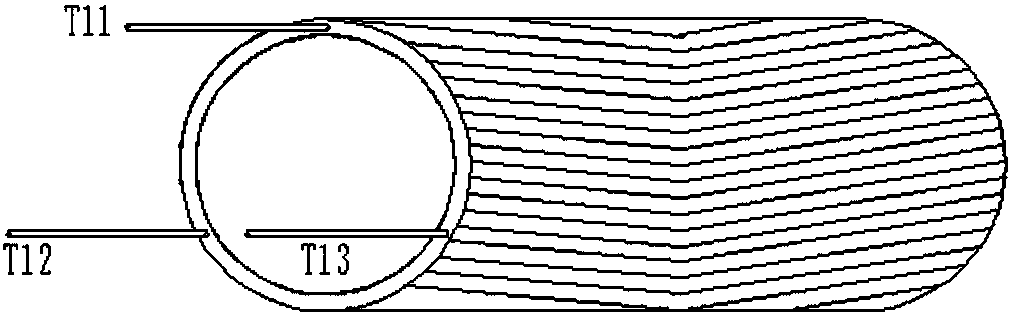

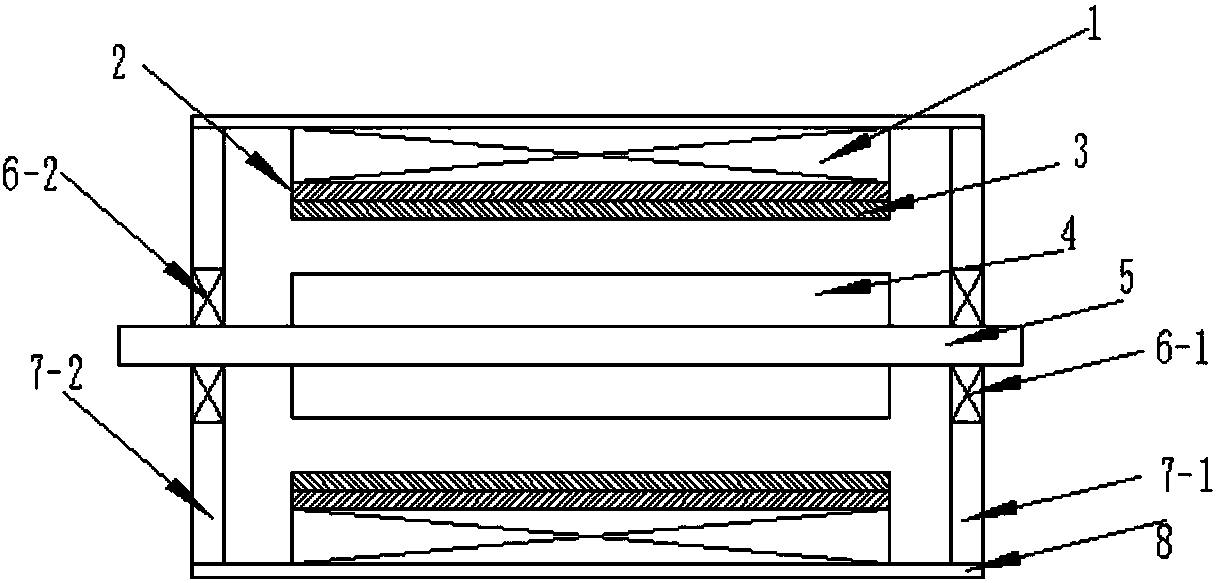

[0028] Taking the double-layer coil as an example, such as figure 1 and figure 2 As shown, the manufacturing process of the single-layer coil: the winding mold is hexagonal, and the self-adhesive enameled wire is wound along the winding mold. The initial lead is recorded as T11. Wire, continue to wind the B-phase winding, lead out T13, then continue to wind the C-phase winding without wires, lead out T11 (because the lead wire here will be connected with the first lead-out wire T11 in parallel, so it is also recorded as T11). After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com