Thermal relay temperature compensation structure

A thermal relay and temperature compensation technology, which is applied in the direction of circuits, electrical components, protective switch operation/release mechanisms, etc., can solve the problem of uncontrollable bending characteristics, damage to the molecular structure and physical properties of double gold, and the inability to ensure consistent tripping characteristics of thermal relays To improve the consistency of the tripping characteristics and achieve the effect of temperature compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

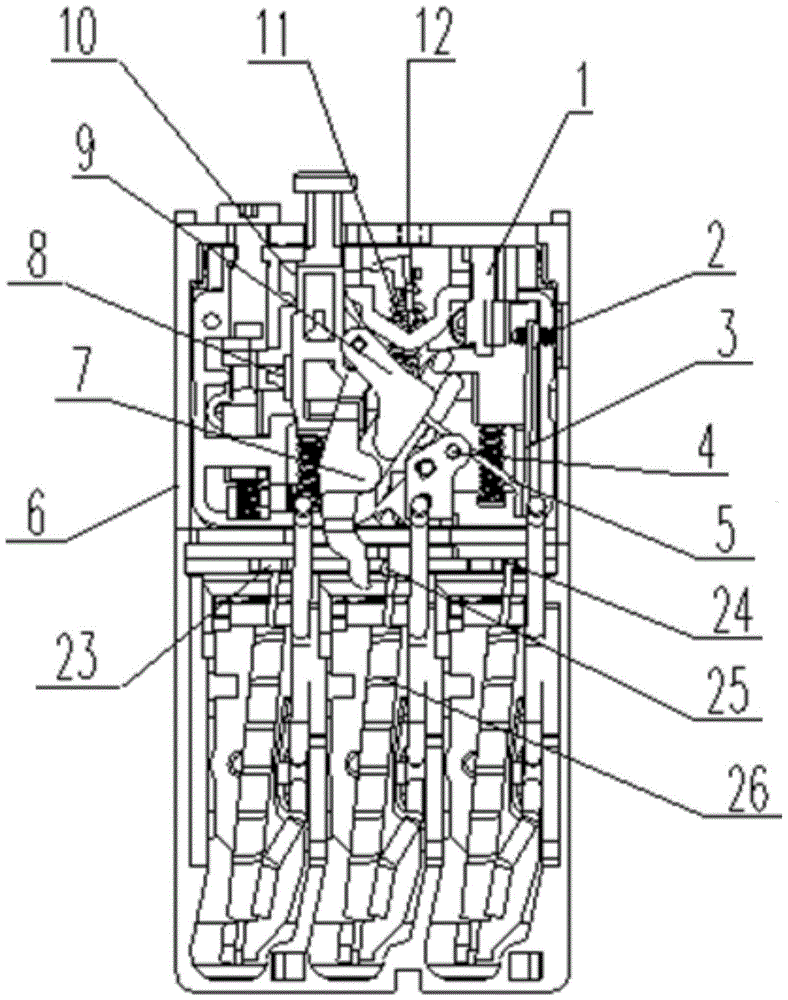

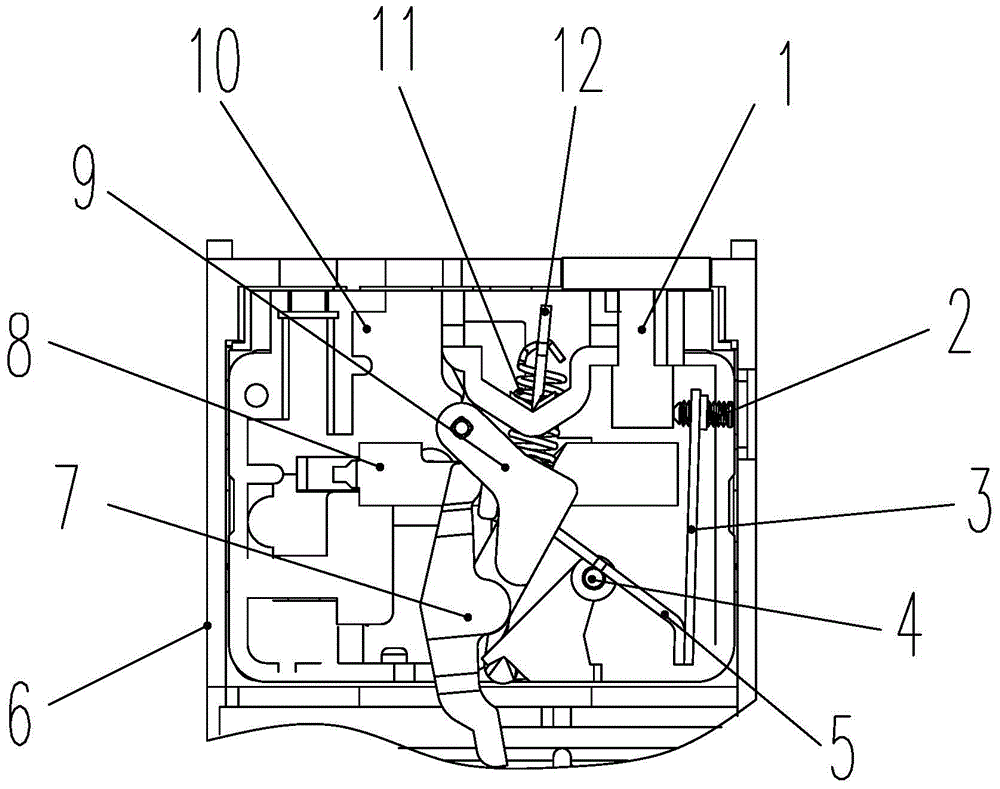

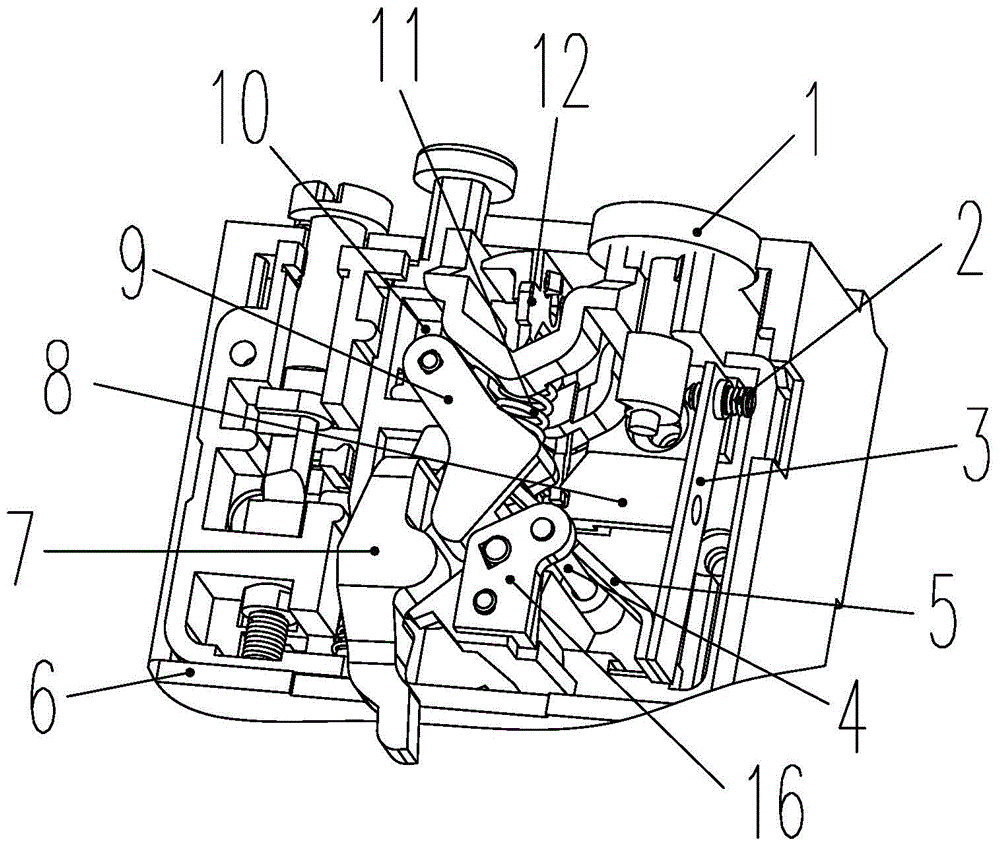

[0031] The following is attached Figures 1 to 17 The given examples further illustrate the specific implementation of the thermal relay temperature compensation structure of the present invention. The temperature compensation structure of the thermal relay of the present invention is not limited to the description of the following embodiments.

[0032] Such as Figure 1-5 As shown, the thermal relay temperature compensation structure of this embodiment includes a casing 6, and a support seat 10 is provided inside the casing 6. A tripping device connected to the main double metal 26 is provided on the support seat 10, and is in contact with the tripping device. The temperature compensating device includes a supporting member 5 and a straight auxiliary double gold 3, a rotating shaft 4 is fixed in the middle of the supporting member 5, and the rotating shaft 4 is installed on the supporting seat 10, and the supporting member 5 can rotate around the rotating shaft 4, and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com