Vapor etching alignment method and vapor etching alignment equipment

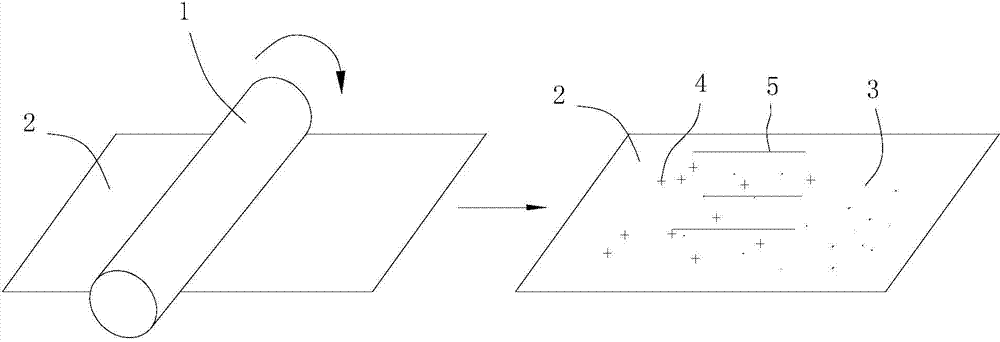

An alignment and equipment technology, applied in optics, instruments, nonlinear optics, etc., can solve problems affecting the quality of glass panels, and achieve the effect of controlling liquid crystal alignment and avoiding surface particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

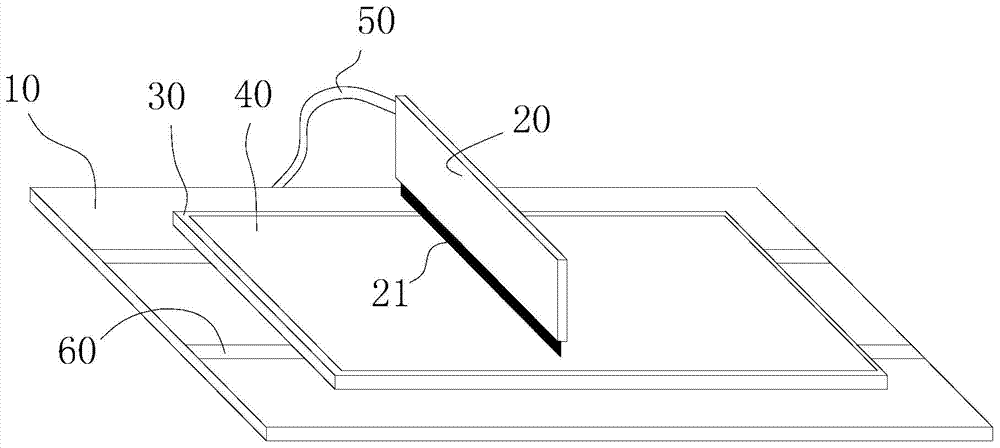

[0026] The present invention will be further described below with reference to the accompanying drawings.

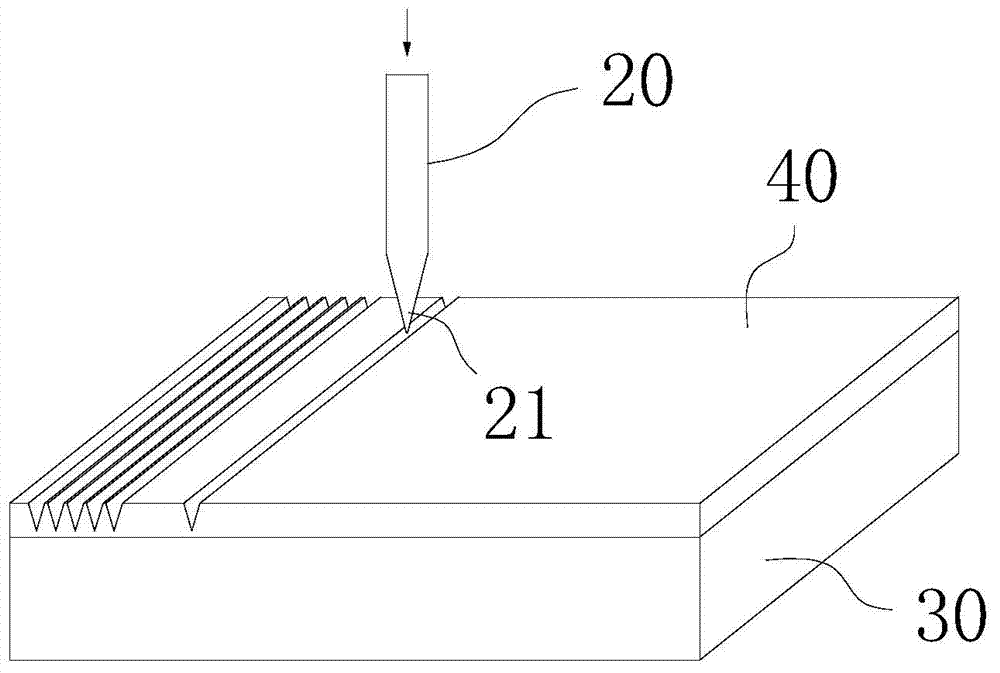

[0027] Such as figure 2 As shown, the gas etching alignment equipment provided by the embodiment of the present invention includes a platform 10 for carrying a glass substrate 30 for operation; a spray gun 20 is arranged above the platform 10, and a plurality of nozzles 21 are evenly arranged side by side on the spray gun 20 , the nozzle 21 is aimed at the glass substrate 30, and an alignment film 40 is formed on the glass substrate 30; a high-pressure air injection system 50 is connected to the spray gun 20 for providing high-pressure airflow to the spray gun 20; a moving system 60 is also included for driving the platform 10 to move , so that the platform 10 and the spray gun 20 are relatively moved, so that under the use of high-pressure air flow, the alignment film 40 will produce grooves (see image 3 ). In this embodiment, according to the needs of the grooving,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com