Automatic clamping device for flaw detection of steel wire rope

A clamping device and steel wire rope technology, which is applied in the field of automatic clamping devices for steel wire rope flaw detection, can solve the problems of low clamping accuracy, low degree of automation, and slow manual inspection speed, and achieve the effect of accurate data and reduced jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The automatic clamping device of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

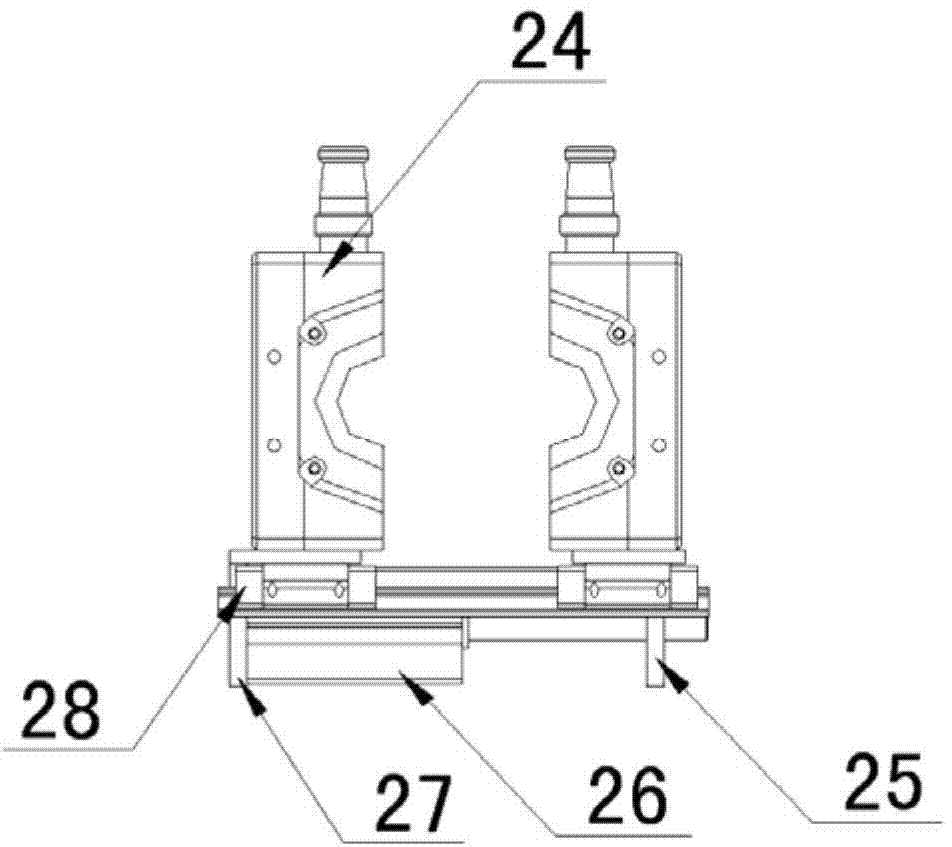

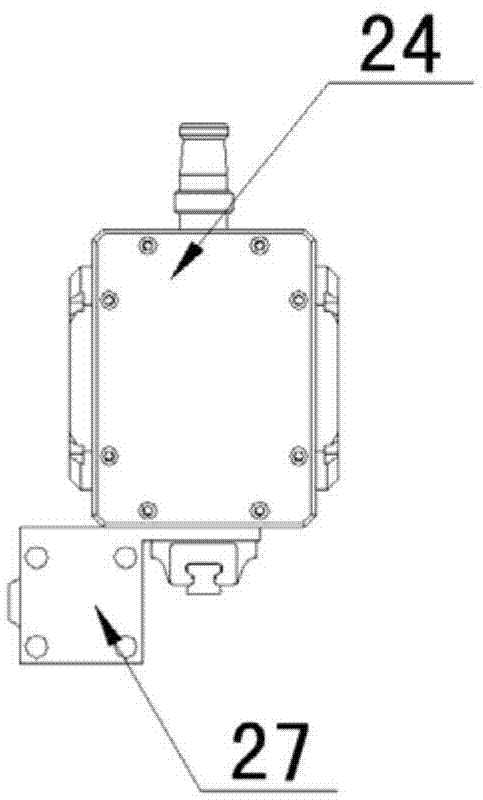

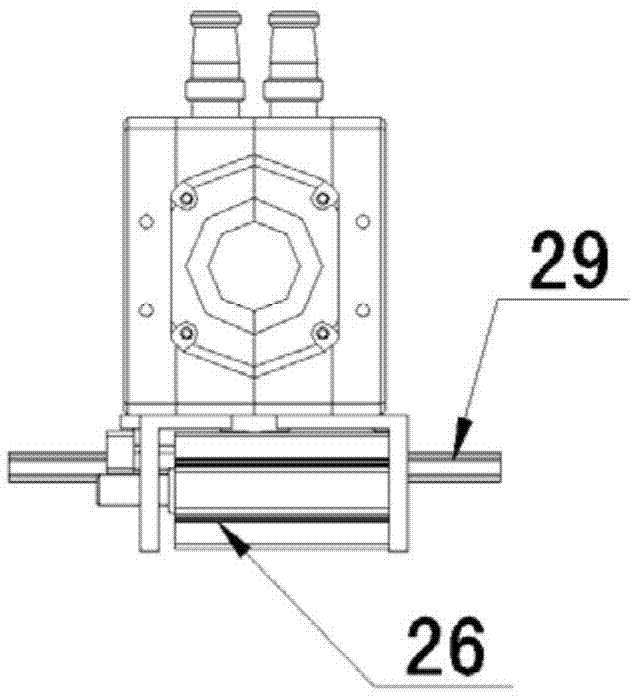

[0034] Such as figure 1 As shown, the device can be divided into three parts: including the base 3, the chassis 2 and the frame assembly 1 arranged on the base 3. The main components include fixed seat 4, cylinder a5, track 6, slider a7, box body 8, solenoid valve 9, clamping assembly 10, guide mechanism 11, support rod 12, shaft a13, triangle connecting rod 14, shaft b15, shaft c16, base 17, cylinder b18, connecting rod 19, shaft d20, shaft e21, shaft f22, shock absorber 23, probe 24, support plate a25, cylinder c26, support plate b27, slider b28, slide rail 29, pin 30, spring 31, pressing block 32, guide block 33.

[0035] Wherein: cabinet 2 comprises the box body 8 of rectangular structure that the electromagnetic valve 9 that links to each other with PLC is housed inside, see image 3 As shown; the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com