Testing device for anti-erosion performance of pavement base material and testing method

A technology of pavement base material and test device, which is applied in the direction of applying repetitive force/pulse force to test material strength and test wear resistance, and can solve the problem of no material scouring simulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

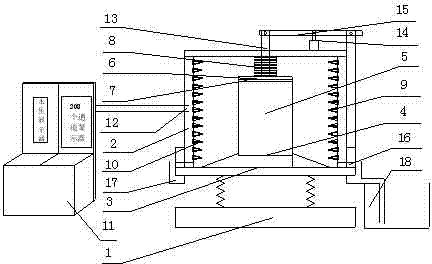

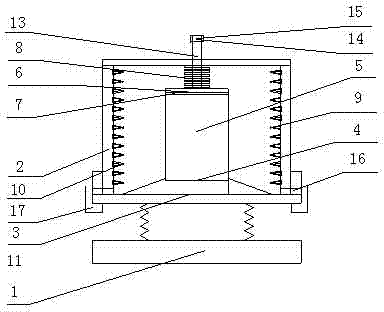

[0040] A test device and test method for anti-erosion performance of pavement base materials, including a set of vibrating table 1, the frequency range of the vibrating table is between 0-10kHz, the vibration amplitude of the vibrating table is adjusted by adjusting the frequency, and the test piece is preconditioned by changing the direction of water flow. Scour to wash away unbonded or loose particles on the surface of the test piece.

[0041] A scour bucket 2 is arranged on the vibrating table, a base is consolidated on the bottom surface of the scour bucket 2, and a set of lower fixer 3 is arranged on the base. 2cm, the outer slope of the cone shape is 1:3, a groove is set on the top surface of the lower fixer, the inner diameter of the groove is 2mm larger than the diameter of the test piece, the anti-friction geotextile 4 is placed in the groove, and the test piece 5 is placed on the geotextile , the top surface of the specimen is stabilized by a pressure plate 6, and a ...

specific Embodiment 2

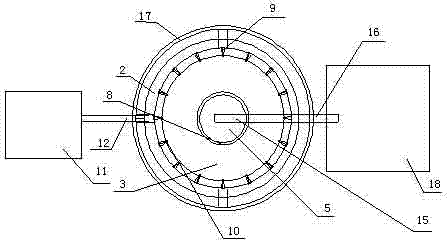

[0047] A test device and test method for anti-erosion performance of pavement base materials, comprising a double-layer cylindrical transparent plastic drum, a computer can be set at an interval of 22.5° in the circumferential direction and 3 cm in the vertical direction on the inner wall of the double-layer cylindrical transparent plastic drum. Adjust the direction of the water nozzles, that is, set 16 water nozzles in the circular direction of the cylinder, and set 13 water nozzles in the vertical direction, a total of 208 nozzles, and control the spraying direction of different water nozzles through computer programs. The water nozzles can Rotate and spray water on the test piece to simulate the erosion of raindrops on the material from different directions under complex conditions.

[0048] The computer can adjust the direction of the water nozzle, and a positioning device is installed at the end of each water nozzle, which is connected to the computer through wireless, and...

specific Embodiment 3

[0063] A test device and test method for anti-scouring performance of pavement base materials. The scour bucket is a double-layer cylindrical transparent plastic drum, and a water level scale is arranged on the outer surface of the double-layer cylindrical transparent plastic drum. The inner diameter is 40cm, and the outer diameter is 50cm. The height is 30cm, the bottom of the drum is integrated with the wall of the drum, the top of the drum is provided with an external helical thread, and the inner wall of the drum is provided with a matching internal helical thread, the cap can be tightened clockwise, and the drum can be disassembled counterclockwise The lid is provided with a round hole at the center of the top of the bung, and the size of the hole matches the diameter of the pressure rod.

[0064] Set a computer-adjustable water nozzle on the inner wall of the double-layer cylindrical transparent plastic drum at an interval of 22.5° in the circumferential direction and 3cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com