Drainage method enabling underground comprehensive pipe gallery to penetrate through canal in dry season

A technology of integrated pipe gallery and river channel, applied in water conservancy projects, underwater structures, water conservancy engineering equipment, etc., can solve the problems of poor stability, high cost, low construction efficiency, etc., to ensure waterproof and stable, and ensure safe operation. , the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

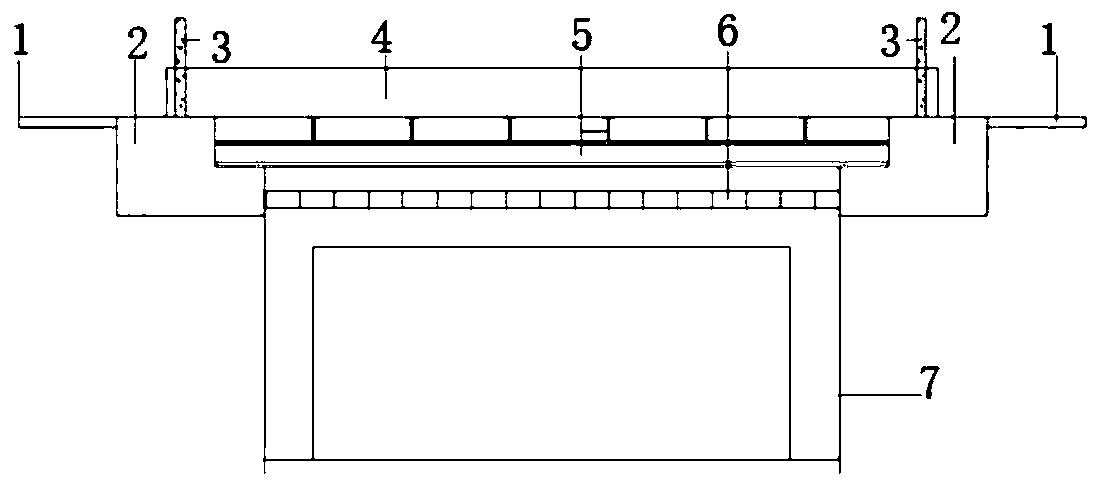

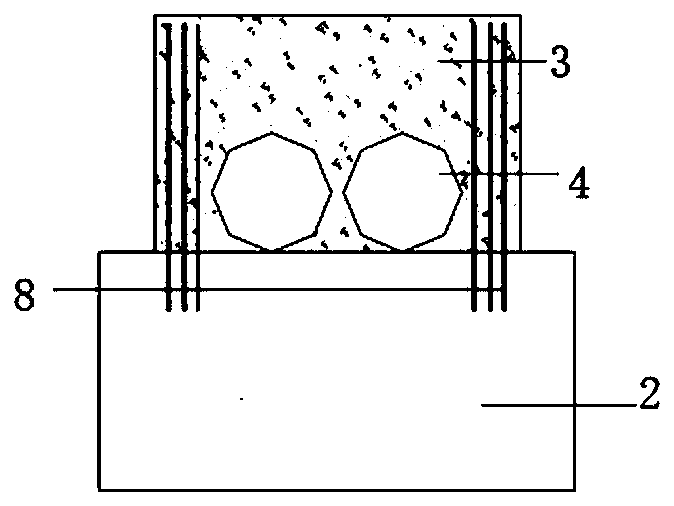

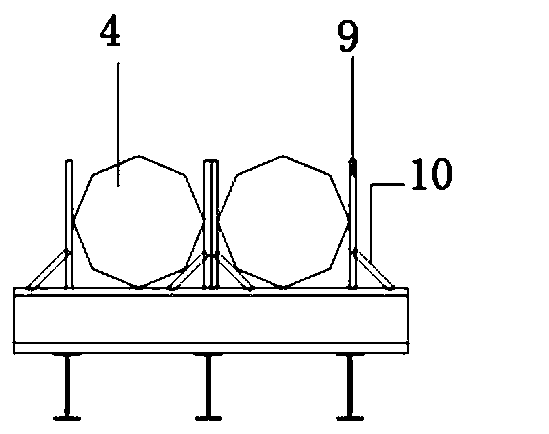

[0038] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-4 Shown, the concrete construction mode of the inventive method is as follows:

[0039] 1) The sequence of the overall plan: construction of diversion canal 13 and water pipe 4 system → water pipe 4, diversion canal 13 water injection test passed → original river canal diversion to diversion canal 13 and water pipe 4 → sealing both ends of the original river canal → completion of river canal diversion → Excavation of foundation pit and subsequent construction of pipe gallery structure → Backfilling of foundation pit → Restoration of river canal → Drainage of river canal → Backfilling of diversion canal → Dismantling and recycling of steel conduit and Bailey rack system;

[0040] 2) Construction process of the water pipe: Excavate the earthwork to the specified foundation pit elevation → install steel sheet piles 7 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com