Flushable ultra-filter water purifier

A water purifier and water purification technology, applied in the direction of filtration treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of inconvenient operation, time-consuming, troublesome operation, etc., and achieve the effect of simple operation and less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

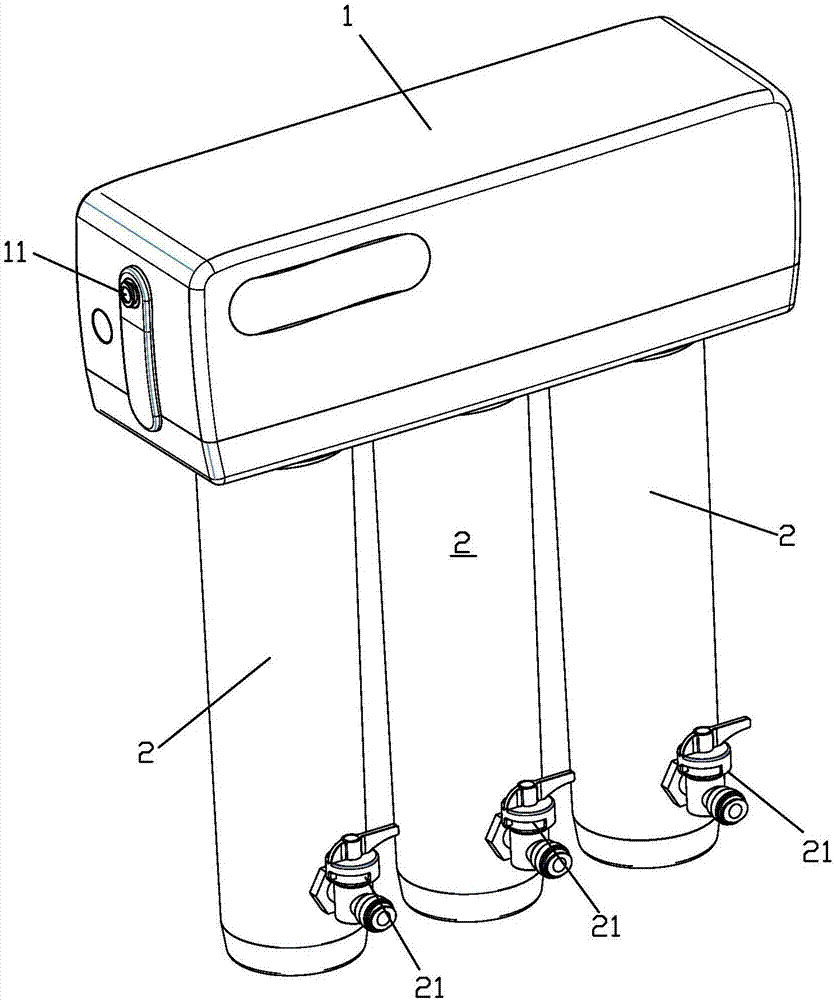

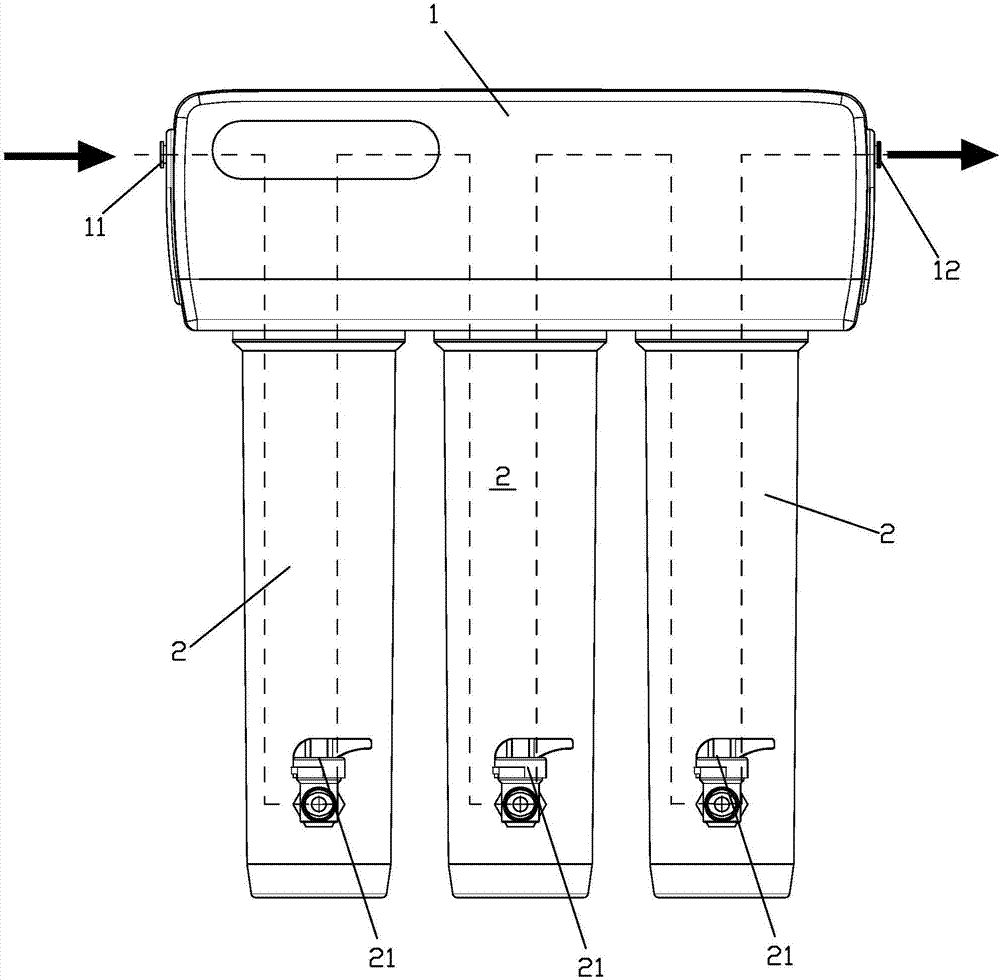

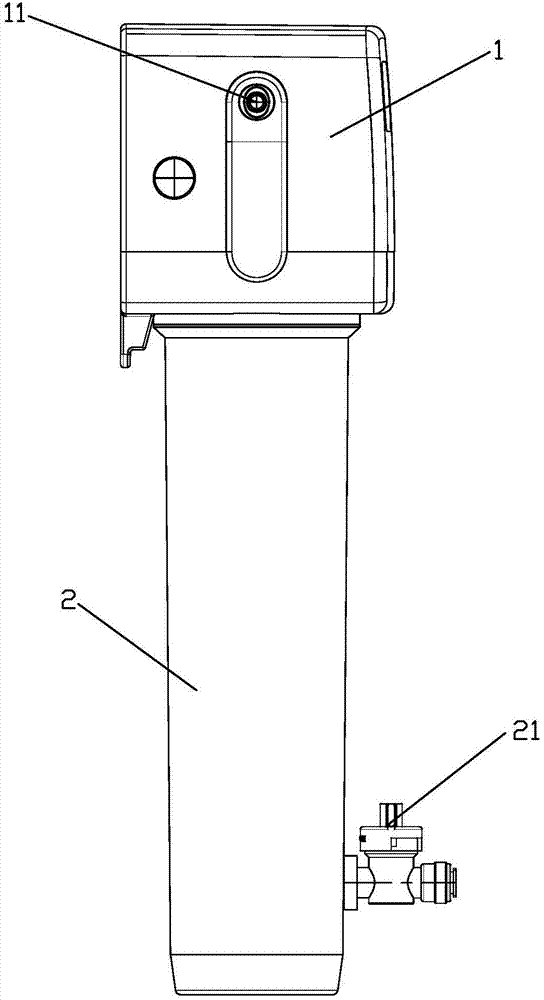

[0029] Please check Figure 1 to Figure 7 , a flushable ultrafiltration water purifier, including a machine head part 1 and three filter core parts 2, taking the three filter core part 2 as an example in this embodiment, the three filter core parts 2 are respectively defined as the first-stage filter core according to the order of water flow Part, second-stage filter element part and third-stage filter element part, but not limited thereto, two or more filter element parts 2 can be set as required.

[0030] The machine head part 1 is provided with connecting structures 3 equal in number to the filter core part 2 , and the filter core part 2 is detachably attached to the machine head part 1 through the connecting structures 3 . The filter element part 2 is provided with a filter element inlet, a filter element outlet and a sewage outlet. The sewage outlet is provided with a switch valve 21 to control the opening and closing of the sewage outlet. The switch valve is like a ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com