A Vapor Compression-Ejection Coupling Refrigeration System with Liquid Intermediate Pressurization

A refrigeration system and liquid technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as system performance degradation, system complexity, and small ejector pressure ratio, and achieve improved system reliability, compact space layout, and The effect of improving system energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

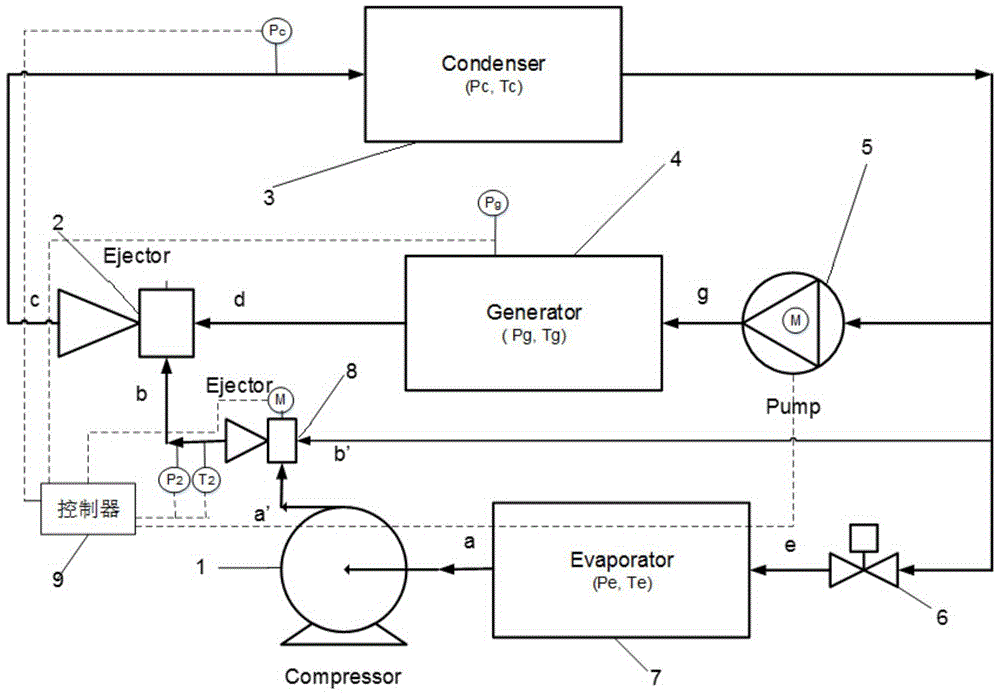

[0019] Such as figure 1 As shown, a vapor compression-ejection coupled refrigeration system with liquid intermediate pressurization includes a condenser 3, and the output of the condenser 3 is divided into three paths, one path is connected to the input end of the pump 5, and the other path is connected to the second ejector 8 One end is connected, the third road is connected with one end of the throttle valve 6, the output end of the pump 5 is connected with the input end of the generator 4, and the output end of the generator 4 is connected with the input end of the condenser 3 through the first injector 2 , the other end of the second ejector 8 is connected to the input end of the ejector 2, and the other end of the throttle valve 6 is connected to the evaporator 7, the compressor 1 and the first ejector 2 in sequence.

[0020] The present invention proposes a liquid inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com