Backlight module structure

A backlight module and light guide plate technology, applied in the field of displays, can solve the problems of difficult to guarantee product quality, difficult to guarantee structural strength, loose components, etc., and achieve the effects of product quality assurance, narrow structure, and stable structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

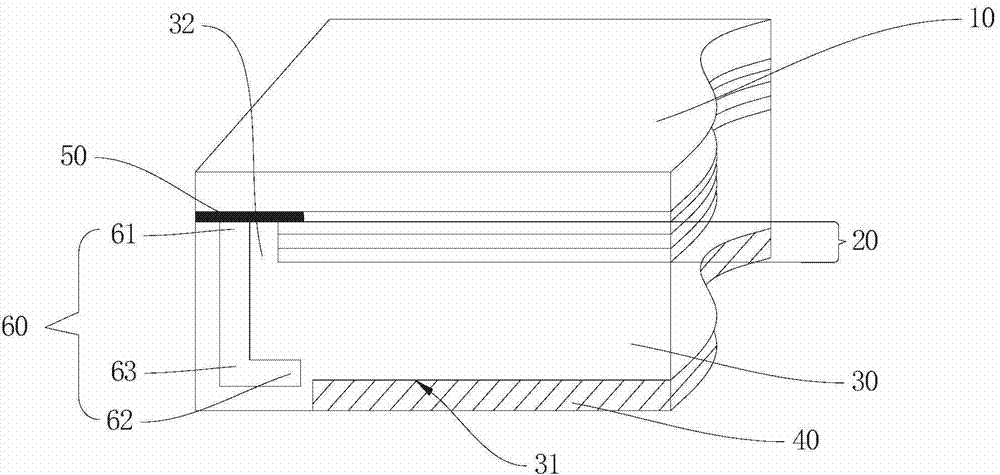

[0012] The invention provides an improved backlight module structure, which can realize a narrow frame and ultra-thin design while ensuring the structural strength of the product.

[0013] The backlight module structure of the present invention, such as figure 1 As shown, it includes a display panel 10, an optical film 20, a light guide plate 30, and a reflective sheet 40 stacked up and down, as well as a light-shielding glue 50 and an iron frame 60 arranged on the bottom side of the display panel. Wherein, the optical film is formed by stacking three light-transmitting films.

[0014] Wherein, the side portion 32 of the light guide plate 30 extends upward through the side wall of the optical film 20 and is connected to the display panel 10 through the light-shielding glue 50; the bottom of the light guide plate 30 is provided for assembling the reflective sheet 40 的槽31。 The groove 31. In this embodiment, the reflective sheet 40 is adhered to the groove 31 by glue. Of course, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com