Pneumatic high-pressure grease filling machine

A technology of pneumatic high-pressure oiler, applied in the direction of engine components, engine lubrication, mechanical equipment, etc., can solve the problem of affecting the normal operation of the pneumatic high-pressure oiler, reducing the oil injection pressure of the pneumatic high-pressure oiler, and wasting a lot of time for disassembly and maintenance And other problems, to achieve the effect of good elasticity, faster oil feeding speed and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

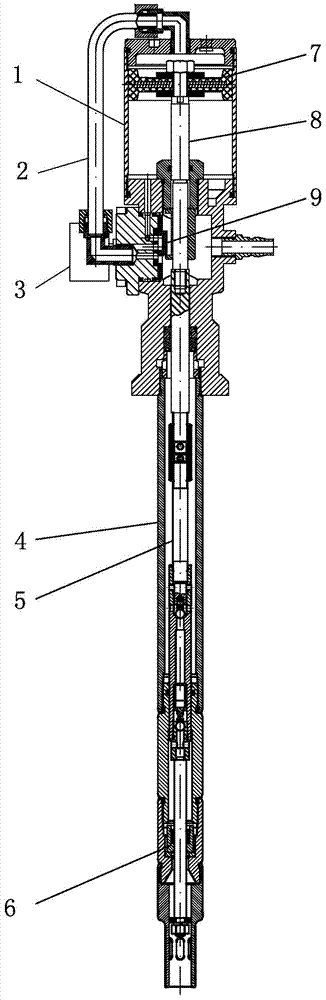

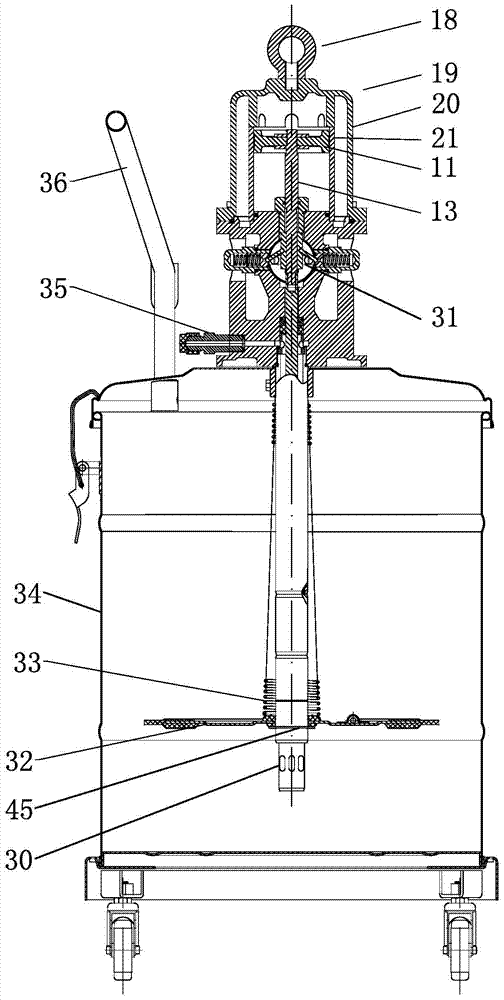

[0025] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 2 -7:

[0026] Pneumatic high-pressure butter oiling machine, including barrel body 34 containing butter, oil injection pump set on barrel body 34, the reciprocating movement of piston rod 13 of the cylinder 19 of the oil injection pump drives the lifting plate 40 to pressurize the butter through the oil outlet joint 35 Sent out, the reciprocating movement of the piston rod 13 drives the reversing valve 31 alternately so that if the air supply port 16 of the reversing valve 31 is connected to the piston upper chamber 41 and the exhaust port is connected to the piston lower chamber 42, the air supply port 16 is connected to the piston lower chamber 42. It is connected with the piston lower chamber 42 and the exhaust port is connected with the piston upper chamber 41. The cylinder 19 includes an inner cylinder 21 and an outer cylinder 20 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com