Modular steel form-concrete composite arch bridge and its suspension cable suspension construction method

A construction method and concrete technology, applied in the field of bridge construction, to achieve the effect of low production cost, precise geometric dimensions, and convenient suspension hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

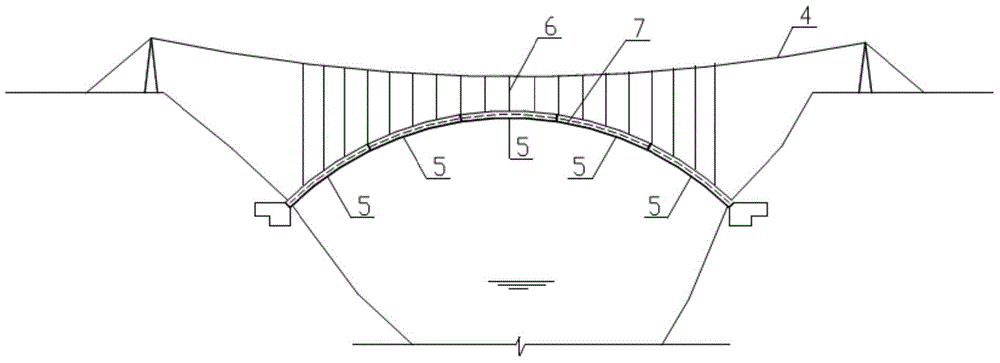

[0061] The application environment of this embodiment is a small pedestrian bridge in a mountainous area, with a clear span of 30m and a vertical height of 5m. The design load is a pedestrian load of 3.5kPa. The composite arch bridge of this embodiment includes: a modular composite arch ring 1 with cast-in-situ concrete 14 and vertical columns 3 , bridge deck girders and bridge decks 2 arranged thereon.

[0062] The modular composite arch ring 1 is specifically composed of five assembled steel arches 7, and each assembled steel arch 7 includes seven modular steel mold units 5 fixedly connected in the arc length direction.

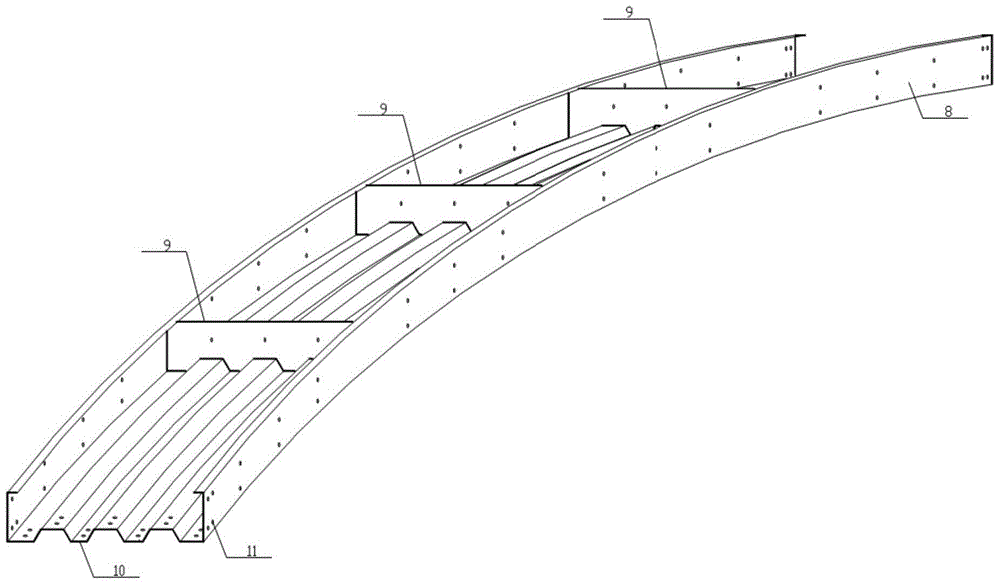

[0063] The steel mold unit 5 is formed by mechanical stamping, bending and welding (riveting), and includes: a bottom plate 10, side plates 8 on both sides of the bottom plate and multiple vertical transverse partitions 9 perpendicular to the axis of the arch.

[0064] The section along the length direction of the bottom plate 10 is an arc surface, and the...

Embodiment 2

[0086] The application environment of this embodiment is a medium-sized arch bridge on a mountain road, with a clear span of 50m and a rise-span ratio of 1 / 6. The design load is road-II class. Using a method similar to that of Example 1, the full width of the bridge deck after construction in this example is 12m. The main arch ring is a catenary arch without hinges of equal cross-section, and the thickness of the arch ring is 0.8m. There are 8 main arch rings, each 15m wide, and each arch ring is composed of 15 steel mold units.

Embodiment 3

[0088]The application environment of this embodiment is a large arch bridge on a highway in a mountainous area, with a clear span of 112m and a rise-span ratio of 1 / 5.3. The design load is road-II class. Using a method similar to that of Example 1, the full width of the bridge deck after construction in this example is 20m, the main arch ring is a variable-section catenary without hinge arch, the section thickness of the vault top is 0.8m, and the section thickness of the arch foot is 1.5m. It adopts the form of steel mold-concrete composite arch. There are 10 main arch rings, each 2m wide, and each arch ring is composed of 30 steel mold units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com