A Finite Element Modeling Method for Arc Additive Manufacturing

A technology of additive manufacturing and modeling methods, applied in CAD numerical modeling, design optimization/simulation, calculation, etc., can solve problems such as violation of numerical simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

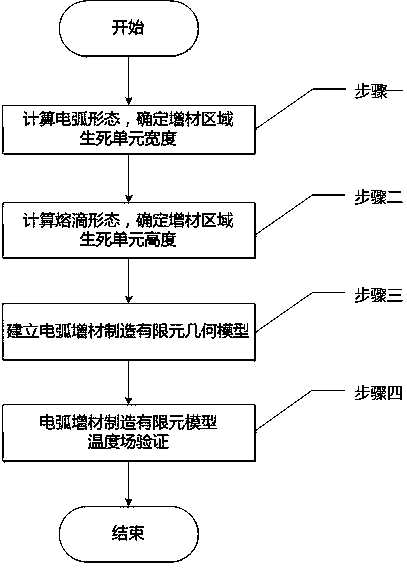

[0081] The following is based on figure 1 The specific embodiment of the present invention is further described:

[0082] The invention proposes a finite element modeling method for arc additive manufacturing. The simulation process of arc additive manufacturing combines arc shape simulation technology, droplet shape simulation technology and finite element simulation technology, and is verified by experiments. Determine the geometric dimensions of the life and death units in the additive area before the meta-modeling, and realize the accurate calculation of the finite element simulation of the arc additive manufacturing. The main process is as follows figure 1 shown. The present invention is realized through the following steps:

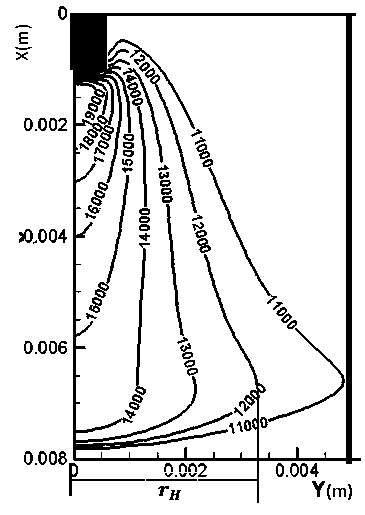

[0083] Step 1: Calculate the arc shape and determine the width of the life and death unit in the additive area;

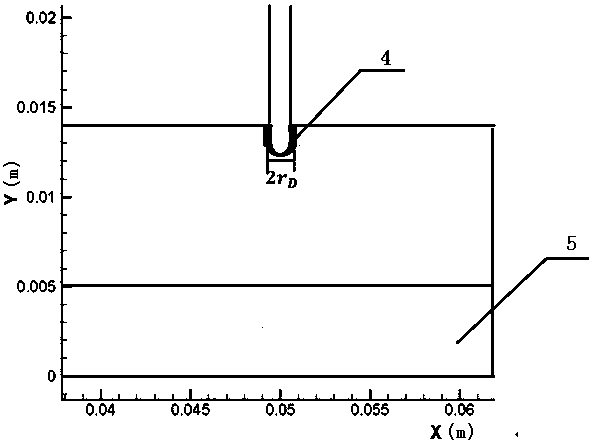

[0084] Step 2: Calculate the shape of the droplet 4, and determine the height of the life and death unit in the additive area;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com