Asphalt hot material mixing machine

A technology of mixing machine and hot material, applied in the direction of roads, road repair, roads, etc., can solve the problems of high price, complex structure, poor energy saving, etc., and achieve the effect of simple operation, smooth entry and exit, and temperature maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

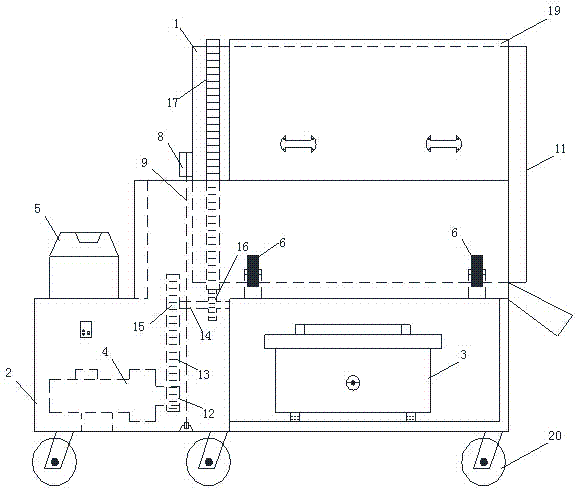

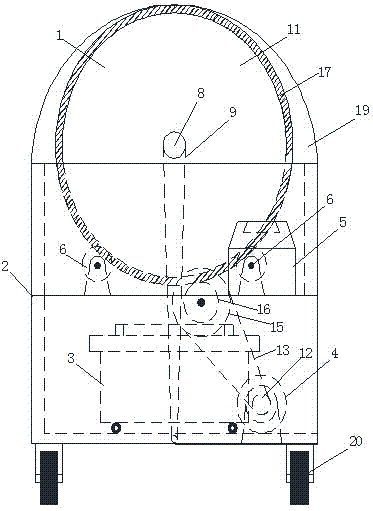

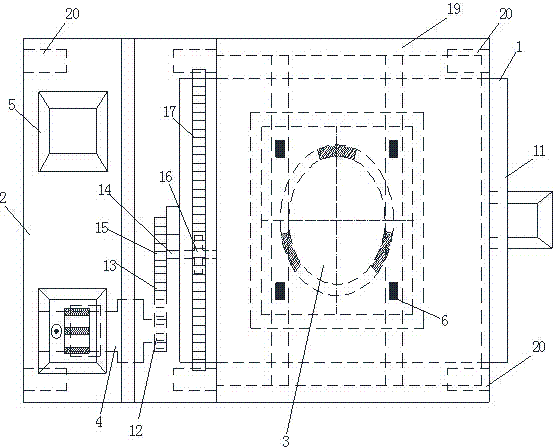

[0048] Such as Figure 1-7 Shown: an asphalt hot material mixer, which includes a mixing tank 1 with an opening 11 on one side, a frame 2, a heating furnace 3, a motor 4 fixed on the frame 2, an oil tank 5, and a transmission device; The mixing bucket 1 is placed on the load-bearing roller 6 arranged on the frame 2, and the corresponding frame 2 on the left and right sides of the mixing bucket 1 is also provided with limit rollers 7, and the mixing bucket 1 is additionally equipped with a rotating pulley. 8. The rotating pulley 8 is connected to the additional steel wire rope 9 connected to the frame 2, and the inside of the mixing bucket 1 is also provided with a continuous spiral stirring piece 10, and the opening 11 of the mixing bucket 1 is also provided with a belt A cover with an observation hole; four load-bearing rollers 6 are symmetrically arranged on both sides of the bottom of the mixing bucket 1, and the rotation axis of the mixing bucket 1 and the load-bearing rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com