Method for desulfurizing molten iron

A hot metal desulfurization and hot metal technology, applied in the field of steelmaking, can solve the problems of large desulfurization agent consumption and unsatisfactory desulfurization effect, and achieve the effects of reducing the temperature loss of molten iron, improving kinetic conditions, and small temperature loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

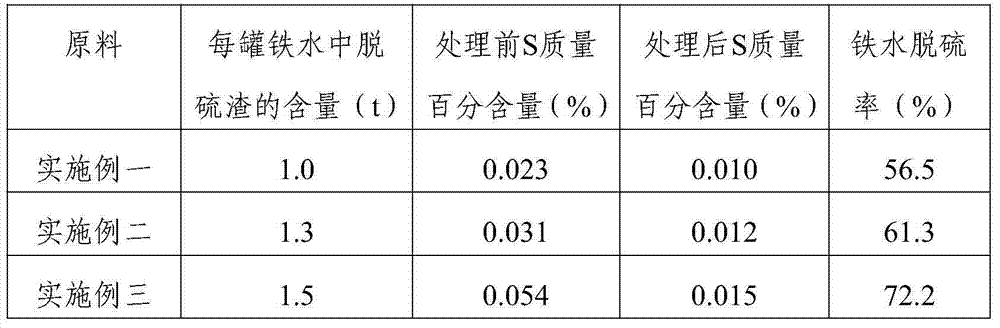

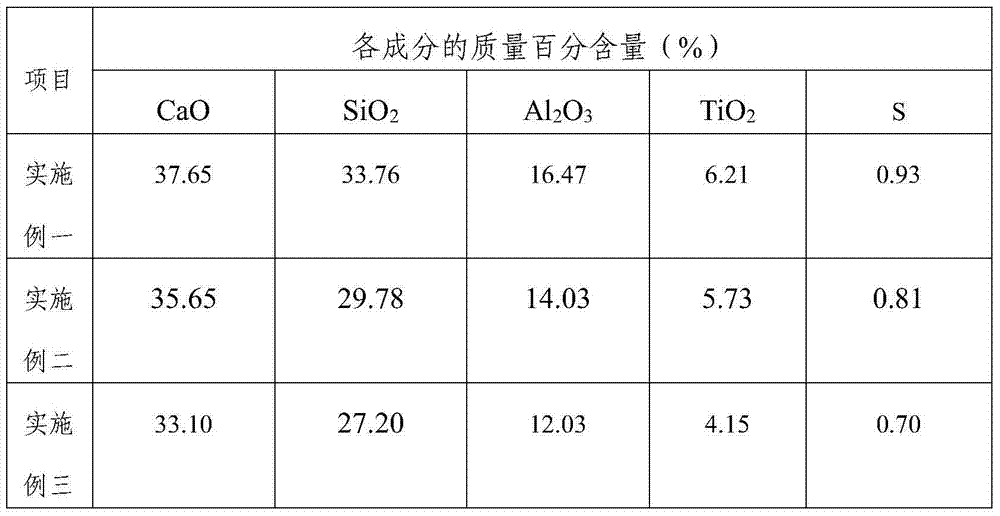

Embodiment 1

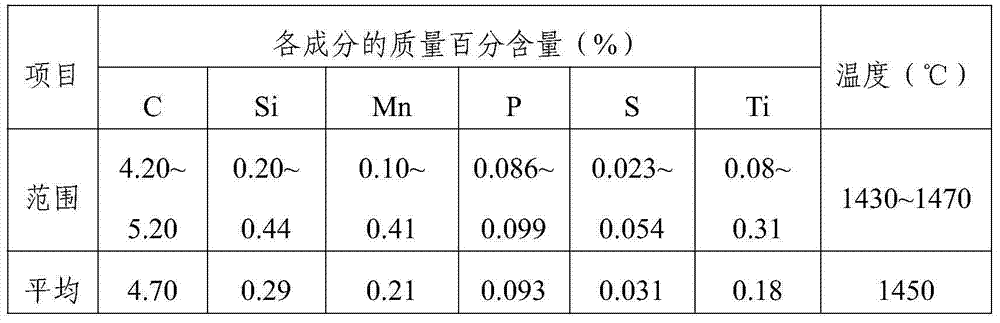

[0026] A method for desulfurizing molten iron, comprising the steps of:

[0027] (1) When tapping the blast furnace, add active lime to the molten iron tank. The weight of each tank of molten iron is 90t, and the amount of active lime added is 2.8kg / t molten iron, so that the molten iron and lime powder are mixed to improve the desulfurization kinetics , to achieve the purpose of sufficient desulfurization, the mass percentage of CaO in the active lime is 88%, and the activity is 302ml;

[0028] (2) After the molten iron arrives at the steelmaking plant, use a wire feeder to feed Ca wire into the molten iron for desulfurization. The feeding amount of Ca is 0.4Kg / t molten iron. The desulfurization by wire feeding method avoids the loss of desulfurizer, and the Ca Strong desulfurization ability, compared with other desulfurizers, the temperature loss of molten iron is small;

[0029] (3) After the desulfurization treatment of molten iron, remove the desulfurization slag with a ...

Embodiment 2

[0031] A method for desulfurizing molten iron, comprising the steps of:

[0032] (1) When tapping the blast furnace, add active lime to the molten iron tank. The weight of each tank of molten iron is 92t, and the amount of active lime added is 3.2kg / t molten iron, so that the molten iron and lime powder are mixed to improve the kinetic conditions of desulfurization , to achieve the purpose of sufficient desulfurization, the mass percentage of CaO in the active lime is 92%, and the activity is 318ml;

[0033] (2) After the molten iron arrives at the steelmaking plant, use a wire feeder to feed Ca wire into the molten iron for desulfurization. The feeding amount of Ca is 0.45Kg / t molten iron. The desulfurization by wire feeding method avoids the loss of desulfurizer, and the Ca Strong desulfurization ability, compared with other desulfurizers, the temperature loss of molten iron is small;

[0034] (3) After the desulfurization treatment of molten iron, remove the desulfurizatio...

Embodiment 3

[0036] A method for desulfurizing molten iron, comprising the steps of:

[0037] (1) When tapping the blast furnace, add active lime to the molten iron tank. The weight of each tank of molten iron is 94t, and the amount of active lime added is 3kg / t molten iron, so that the molten iron and lime powder are mixed to improve the desulfurization kinetics conditions. To achieve the purpose of sufficient desulfurization, the mass percentage of CaO in the active lime is 90%, and the activity is 310ml;

[0038] (2) After the molten iron arrives at the steelmaking plant, the Ca wire is fed into the molten iron by a wire feeder for desulfurization. The feeding amount of Ca is 0.43Kg / t of molten iron. The desulfurization by wire feeding method avoids the loss of desulfurizer, and the Ca Strong desulfurization ability, compared with other desulfurizers, the temperature loss of molten iron is small;

[0039] (3) After the desulfurization treatment of molten iron, remove the desulfurizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com