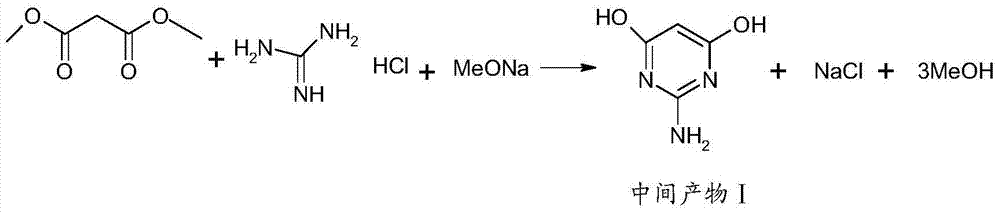

Method for synthesizing 2,5-diamino-4,6-dihydroxypyrimidine hydrochloride

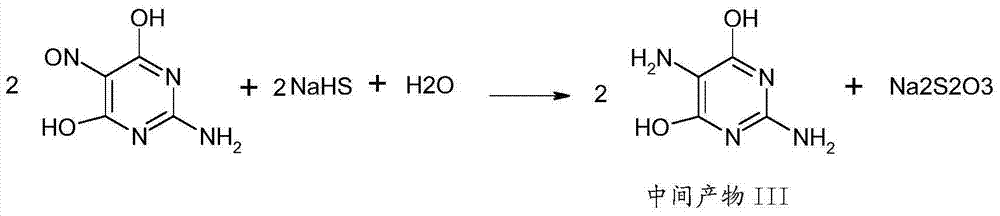

A technology of hydroxypyrimidine hydrochloride and synthesis method, which is applied in the field of synthesis of 2,5-diamino-4,6-dihydroxypyrimidine hydrochloride, which can solve the problems of high catalyst price, cumbersome post-treatment, long reaction time, etc. problem, achieve the effect of reducing production cost, complete reaction and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1), put 298.7g of 28% sodium methoxide solution and 76.4g of guanidine hydrochloride into a four-necked bottle, stir and heat up to 50°C, add 114.4g of dimethyl malonate dropwise, keep the temperature at 50°C during the dropping process, drop After the addition, keep the reaction at 50°C for 3 hours. After the reaction was completed, methanol was recovered by distillation under reduced pressure. After the recovery, 400 g of water was added, and then concentrated hydrochloric acid was added to adjust the pH to 3-4. A total of 165 g of hydrochloric acid was removed, and the intermediate product was obtained by suction filtration and drying to obtain 98.2 g of the intermediate product.

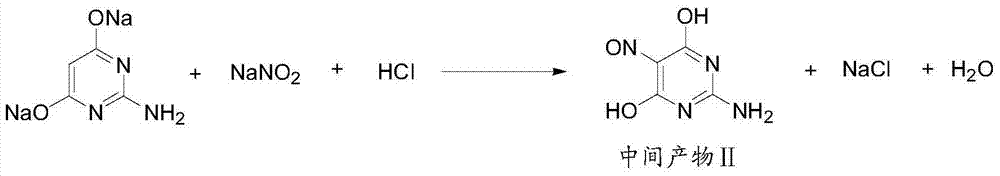

[0030] 2), add intermediate product I98.2g and water 320g in the reactor, then add 30% sodium hydroxide aqueous solution 208g, stir and heat up to 40 ℃, add sodium nitrite 63.5g, then start to drop concentrated hydrochloric acid to adjust to pH = 2-3, after 1 hour, the dropwise addition wa...

Embodiment 2

[0034] 1), put 373.3g of 28% sodium methoxide solution and 76.4g of guanidine hydrochloride into a four-necked bottle, stir and heat up to 40°C, add 124.8g of dimethyl malonate dropwise, keep the temperature at 40°C during the dropping process, drop After the addition, keep the reaction at 40°C for 5 hours. After the reaction, methanol was distilled under reduced pressure to recover methanol. After the recovery, 400 g of water was added, and then glacial acetic acid was added to adjust the pH to pH=4-5. A total of 125 g of deglacial acetic acid was used, cooled to room temperature, suction filtered, and dried to obtain an intermediate product I98.8 g.

[0035] 2), add intermediate product I98.8g and water 350g in the reactor, then add 195g of 30% aqueous sodium hydroxide solution, stir and heat up to 50°C, add sodium nitrite 66.2g, then start to drop concentrated hydrochloric acid to adjust to pH = 2-3, after 1.5 hours, the dropwise addition was completed, kept stirring at 60°...

Embodiment 3

[0039] 1), put 448.0g of 28% sodium methoxide solution and 76.4g of guanidine hydrochloride into a four-necked bottle, stir and heat up to 45°C, add 135.2g of dimethyl malonate dropwise, keep the temperature at 45°C during the dropwise addition, drop After the addition, keep the reaction at 45°C for 4 hours. After the reaction, methanol was distilled under reduced pressure to recover methanol. After the recovery, 400 g of water was added, and then glacial acetic acid was added to adjust the pH to pH=4-5. A total of 126 g of deglacial acetic acid was used, cooled to room temperature, suction filtered, and dried to obtain an intermediate product I99.3 g.

[0040]2), add intermediate product I99.3g and water 380g in the reactor, add 30% sodium hydroxide aqueous solution 198g again, stir and heat up to 50 ℃, add sodium nitrite 69.0g, then start to drop concentrated hydrochloric acid to adjust to pH= 2-3, after 1.5 hours, the dropwise addition was completed, kept stirring at 60°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com