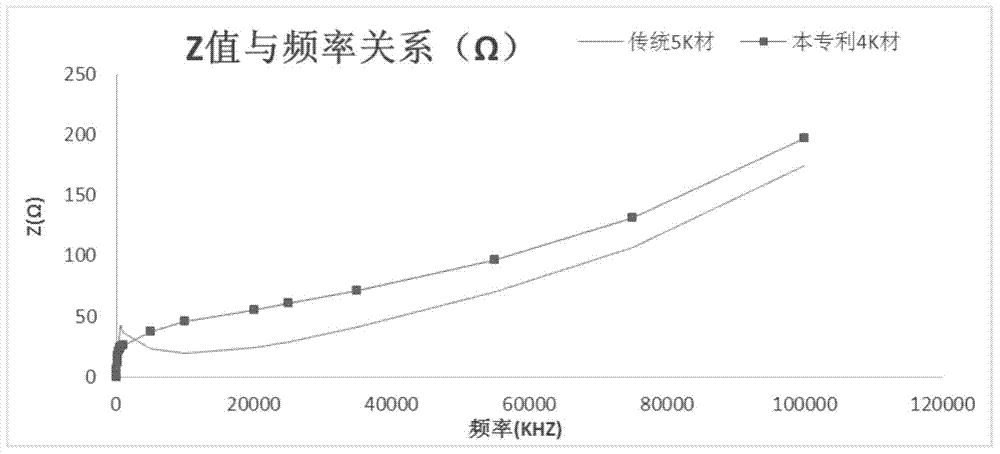

High-frequency high-impedance material of manganese-zinc ferrite and preparation method of high-frequency high-impedance material

A manganese-zinc ferrite, high-impedance technology, applied in the field of ferrite, to achieve the effect of good product compactness, superior performance, and perfect grain development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the above-mentioned manganese-zinc ferrite high-frequency high-impedance material includes:

[0042] 1) preparing manganese zinc ferrite powder;

[0043] Wherein, in step 1), batching, mixing, and ball milling are carried out according to the weight percentage of the main components; the ball-milled powder is put into a resistance furnace for pre-burning, the pre-burning temperature is 850 ° C, and the holding time is 3 hours; Coarse pulverization is carried out after pre-calcination; then microcomponents are added, mixed, and finely pulverized; finally, spray granulation is carried out to adjust the granules to obtain powder.

[0044] 2) pressing the powder into shape to obtain a blank;

[0045] 3) The blank is placed in a closed reactor for sintering at a temperature of 1300-1450° C., then kept for 5-10 hours, and then lowered to below 300° C.

Embodiment 1

[0048] The manganese-zinc ferrite high-frequency high-impedance material provided by Embodiment 1 of the present invention has a main component of 60% Fe in terms of weight percentage 2 o 3 , 15% MnO, 20% ZnO and 4.5% CuO;

[0049] Trace components are: 1100ppmTa 2 o 3 , 1000ppmCaCO 3 , 550ppmCoO, 500ppmTiO 2 , 400ppmNiO, 400ppmSnO 2 、300ppm Bi 2 o 3 、300ppmCr 2 o 3 , 150ppmV 2 o 5 , 150ppmNb 2 o 5 , 80ppmSiO 2 , 10ppmMoO 3 , 40ppmMgO and 20ppmAl 2 o 3 .

[0050] Preparation:

[0051] S11: preparing manganese zinc ferrite powder;

[0052] S12: pressing the powder to form a blank;

[0053] Wherein, S11 and S12 are respectively consistent with step 1) and step 1), and will not be repeated here.

[0054] S13: The blank is placed in a closed reactor for sintering at a temperature of 1340° C. and then kept for 10 hours, and then the temperature is lowered to below 300° C.

[0055] Specifically, in step S13:

[0056] Put the blank in a closed reactor for sinte...

Embodiment 2

[0058] The manganese-zinc ferrite high-frequency high-impedance material provided by Embodiment 2 of the present invention has a main component of 70% Fe in terms of weight percentage 2 o 3 , 14.5% MnO, 13% ZnO and 2% CuO;

[0059] Trace components are: 1300ppmTa 2 o 3 , 1000ppmCaCO 3 , 500ppmCoO, 500ppmTiO 2 , 400ppmNiO, 350ppmSnO 2 、240ppm Bi 2 o 3 , 280ppmCr 2 o 3 , 150ppmV 2 o 5 , 110ppmNb 2 o 5 , 60ppmSiO2 2 , 20ppmMoO 3 , 50ppmMgO and 40ppmAl 2 o 3 .

[0060] Preparation:

[0061] S21: preparing manganese zinc ferrite powder;

[0062] S22: pressing the powder to form a blank;

[0063] Wherein, S21 and S22 are consistent with S11 and S12 respectively, and will not be repeated here.

[0064] S23: The blank is placed in a closed reactor for sintering at a temperature of 1400° C. and then kept for 5 hours, and then the temperature is lowered to below 300° C.

[0065] Specifically, in step S23:

[0066] Put the blank in a closed reactor for sintering. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com