Method for removing impurities from desulphurization gypsum of power plant

A desulfurization gypsum, power plant technology, applied in the field of resource utilization of industrial by-product gypsum, can solve the problems of poor actual effect, inability to separate, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

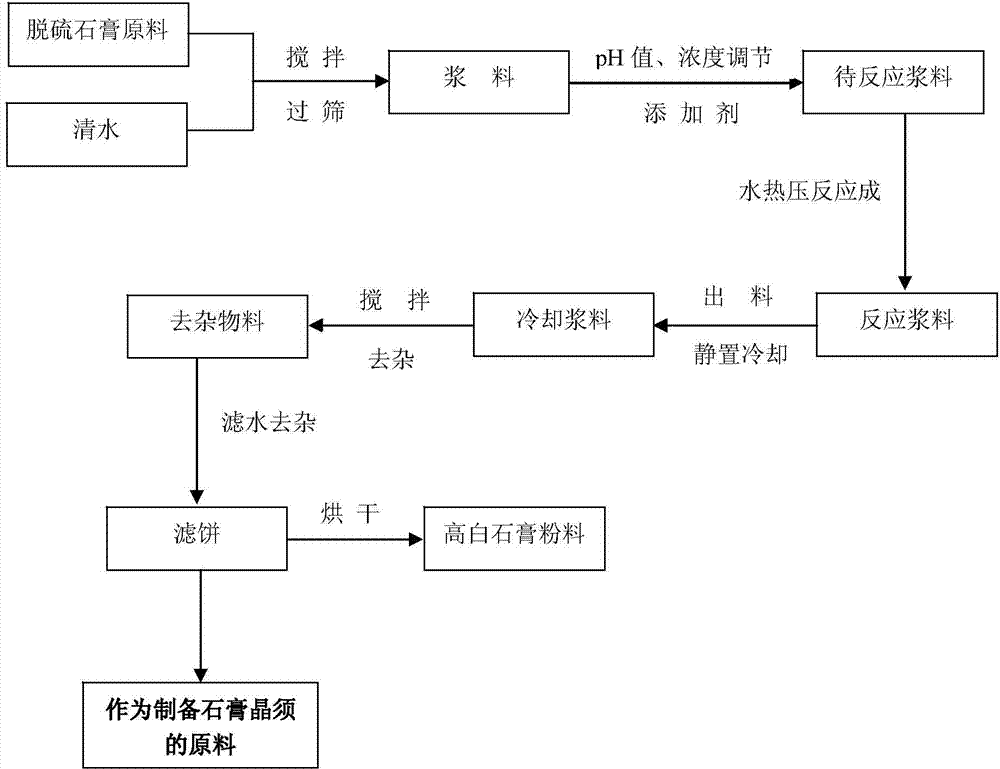

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Weigh 1 kg of dihydrate gypsum raw material obtained by desulfurization in a power plant, measure 6 kg of clear water, stir thoroughly, and pass through a 300-mesh vibrating sieve to remove large particles of impurities. Add 4kg of clear water to the sieved slurry to make the slurry concentration approximately gypsum:water = 1:10; add sulfuric acid to adjust the pH value of the slurry to 2.5, add 50g of sodium chloride, sodium dodecylbenzenesulfonate 5g. Put the adjusted slurry into the high-pressure reactor with enamel lining, set the maximum reaction temperature to 125°C, the reaction pressure to 0.15Mpa, the holding time to 5h, and the stirring speed to 60r / min. After the reaction, the slurry was transferred to a plastic container, allowed to stand and cooled to room temperature, and continued to cool for 1 h after cooling down to room temperature. Stir the cooled slurry, then let it stand still, and pour out the upper layer of turbid liquid after the ini...

Embodiment 2

[0039] Example 2: Weigh 0.8 kg of dihydrate gypsum raw material obtained by desulfurization in a power plant, measure 6 kg of clear water, stir thoroughly, and pass through a 300-mesh vibrating sieve to remove large particles of impurities. Add 4kg of clear water to the sieved slurry to make the slurry concentration approximately gypsum: water = 0.8:10; add sulfuric acid to adjust the pH value of the slurry to 5; add 30g of aluminum sulfate; add sodium dodecylbenzenesulfonate 3g. Put the adjusted slurry into a high-pressure reactor with enamel lining, set the maximum reaction temperature to 160°C, the reaction pressure to 0.60Mpa, the holding time to 0.5h, and the stirring speed to 60r / min. After the reaction, the slurry was transferred to a plastic container, allowed to stand and cooled to room temperature, and continued to cool for 1 h after cooling down to room temperature. Stir the cooled slurry, and then use conventional hydrocyclone separation to remove the tiny particl...

Embodiment 3

[0040] Embodiment 3: the added value of aluminum sulfate in embodiment 2 is increased by 80g, all the other process conditions and methods are unchanged, and the whiteness of the obtained impurity-removing gypsum is 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com