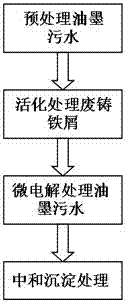

Water-based ink wastewater treatment process

A treatment process, water-based ink technology, applied in the direction of water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of not very good effect, high treatment cost, high chroma of COD value and other problems, to achieve the effect of high chroma removal rate and COD removal rate, high production and application value, and reduced treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The specific processing method is as follows:

[0019] a) Pretreatment of ink sewage, because the water-based ink sewage contains a large amount of acrylic resin, which is very hydrophilic and is particularly sensitive to pH, so first neutralize the ink sewage with a certain amount of hydrochloric acid, and put The pH value of the sewage is adjusted to 3.5; then the sewage is left to stand at room temperature of 20°C for 2 hours, so as to separate the suspended colloidal substances in the sewage and reduce the waste residue content in the sewage. According to the actual test, the COD value of the pretreated ink sewage can be reduced to 900mg / L, and the chroma can be reduced by about 150 times.

[0020] b) Activation treatment of waste cast iron chips, first wash the waste cast iron chips with a certain amount of 10% sodium hydroxide solution to remove the oil on the surface of the waste cast iron chips; then soak the waste cast iron chips with a certain amount of 3% hyd...

Embodiment 2

[0024] The specific processing method is as follows:

[0025] a) Pretreatment of ink sewage, because the water-based ink sewage contains a large amount of acrylic resin, which is very hydrophilic and is particularly sensitive to pH, so first neutralize the ink sewage with a certain amount of hydrochloric acid, and put The pH value of the sewage is adjusted to 4; then the sewage is left to stand at room temperature of 20°C for 3 hours, so as to separate the suspended colloidal substances in the sewage and reduce the waste residue content in the sewage. According to the actual test, the COD value of the pretreated ink sewage can be reduced to 800mg / L, and the chroma can be reduced by about 150 times.

[0026] b) Activation treatment of waste cast iron chips, first wash the waste cast iron chips with a certain amount of 10% sodium hydroxide solution to remove the oil on the surface of the waste cast iron chips; then soak the waste cast iron chips with a certain amount of 3% hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com