Hydrothermal synthesis method of nano-scale zirconium tungstate hollow spheres

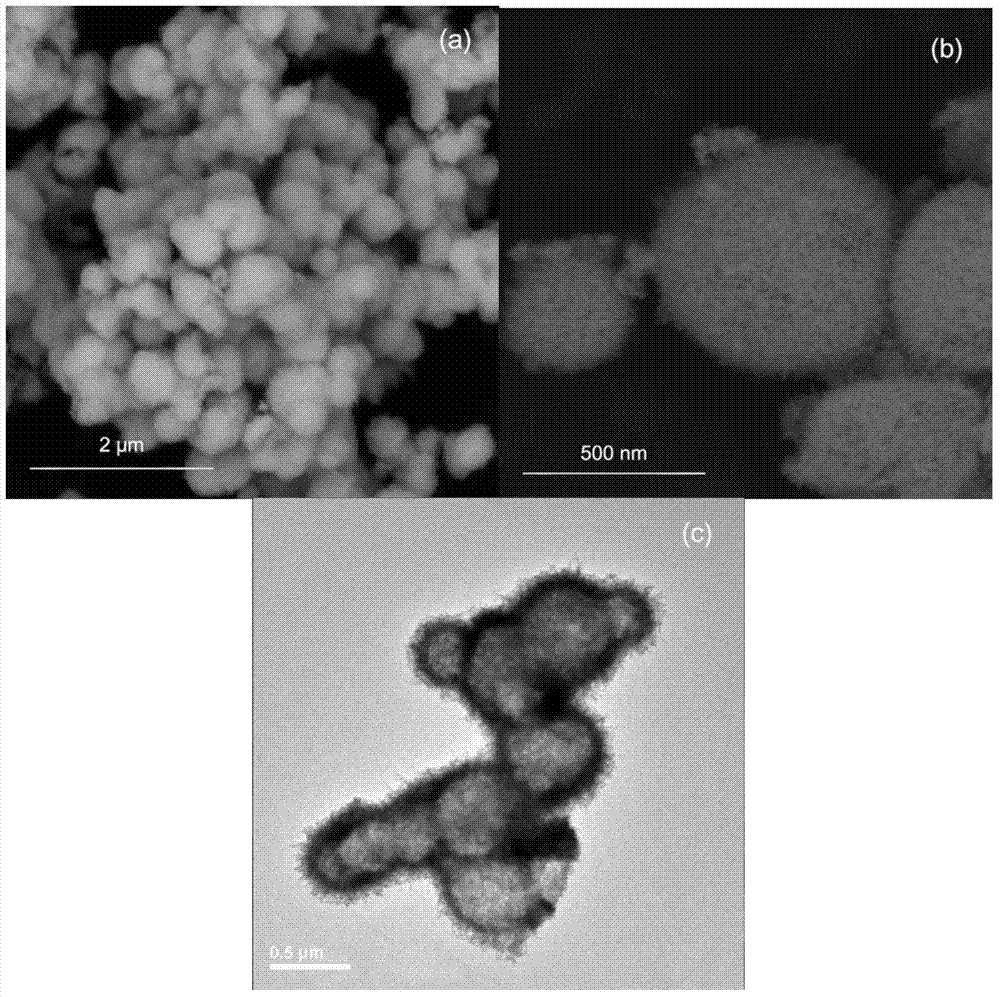

A technology of hydrothermal synthesis and zirconium tungstate, applied in the field of ceramic materials, can solve the problems of particle shape influence, high density, difficult shape control, etc., and achieve the effect of uniform particle size and good negative expansion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Press ZrW 2 o 8 The stoichiometric ratio of zirconium oxychloride (ZrOCl 2 ) and ammonium metatungstate ((NH 4 ) 6 W 12 o 39 ), and were dissolved in water respectively to form solution a (zirconium oxychloride aqueous solution) and solution b (ammonium metatungstate aqueous solution). Under the premise of constant stirring of solution b, solution a was added to solution b to make it fully mixed After obtaining the mixed solution c, keep stirring and heating at 60°C for 2h; add 6mol / l hydrochloric acid to the mixed solution c to adjust the pH to 0.2, keep stirring and heat up to 90°C for 3h to obtain a homogeneous precursor suspension. The precursor suspension was transferred into a hydrothermal reaction kettle and heated at 180 °C for 5 h. After cooling, the supernatant was poured out, and the resulting precipitate was washed with deionized water to remove excess Cl - . After drying the precipitate, move it into a horse boiling furnace and calcinate at 900°C fo...

Embodiment 2

[0019] Press ZrW 2 o 8 The stoichiometric ratio of zirconium oxychloride (ZrOCl 2 ) and ammonium metatungstate ((NH 4 ) 6 W 12 o 39 ), and were dissolved in water respectively to form solution a (zirconium oxychloride aqueous solution) and solution b (ammonium metatungstate aqueous solution). Under the premise of constant stirring of solution b, solution a was added to solution b to make it fully mixed After obtaining the mixed solution c, keep stirring and heating at 65°C for 2h; add 6mol / l hydrochloric acid to the mixed solution c to adjust the pH to 0.2, keep stirring and heat up to 90°C for 3h to obtain a homogeneous precursor suspension. The precursor suspension was transferred into a hydrothermal reaction kettle and heated at 180 °C for 5 h. After cooling, the supernatant was poured out, and the resulting precipitate was washed with deionized water to remove excess Cl - . After drying the precipitate, move it into a horse boiling furnace and calcinate at 900°C fo...

Embodiment 3

[0021] Press ZrW 2 o 8 The stoichiometric ratio of zirconium oxychloride (ZrOCl 2 ) and ammonium metatungstate ((NH 4 ) 6 W 12 o 39 ), and were dissolved in water respectively to form solution a (zirconium oxychloride aqueous solution) and solution b (ammonium metatungstate aqueous solution). Under the premise of constant stirring of solution b, solution a was added to solution b to make it fully mixed After obtaining the mixed solution c, keep stirring and heating at 70°C for 2h; add 6mol / l hydrochloric acid to the mixed solution c to adjust the pH to 0.2, keep stirring and heat up to 90°C for 3h to obtain a homogeneous precursor suspension. The precursor suspension was transferred into a hydrothermal reaction kettle and heated at 180 °C for 5 h. After cooling, the supernatant was poured out, and the resulting precipitate was washed with deionized water to remove excess Cl - . After the precipitate is dried, it is transferred into a horse boiling furnace and calcined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com