Preparation method of carbon-doped molybdenum disulfide nanometer material

A molybdenum disulfide and nanomaterial technology, applied in the field of nanomaterials, can solve problems such as high cost and scarcity in nature, achieve the effects of less pollution, uniform lamella size, and promotion of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take by weighing a certain amount of sodium molybdate and thiourea (CN 2 h 4 S), dissolved in ethylene glycol and ultrapure water in turn, the volume ratio is 3:2, at room temperature, stirred for 2h to make it fully dissolved, then adjusted pH=3 with hydrochloric acid, and finally transferred the above solution to 80ml In a reaction kettle, solvothermal reaction was carried out at 160°C. After 20 hours of reaction, it was taken out, cooled to room temperature naturally, and then washed with ultrapure water and ethanol in sequence, and the black matter was collected and dried in a vacuum oven at 55°C for 14 hours. , and finally get carbon-doped MoS 2 black powder.

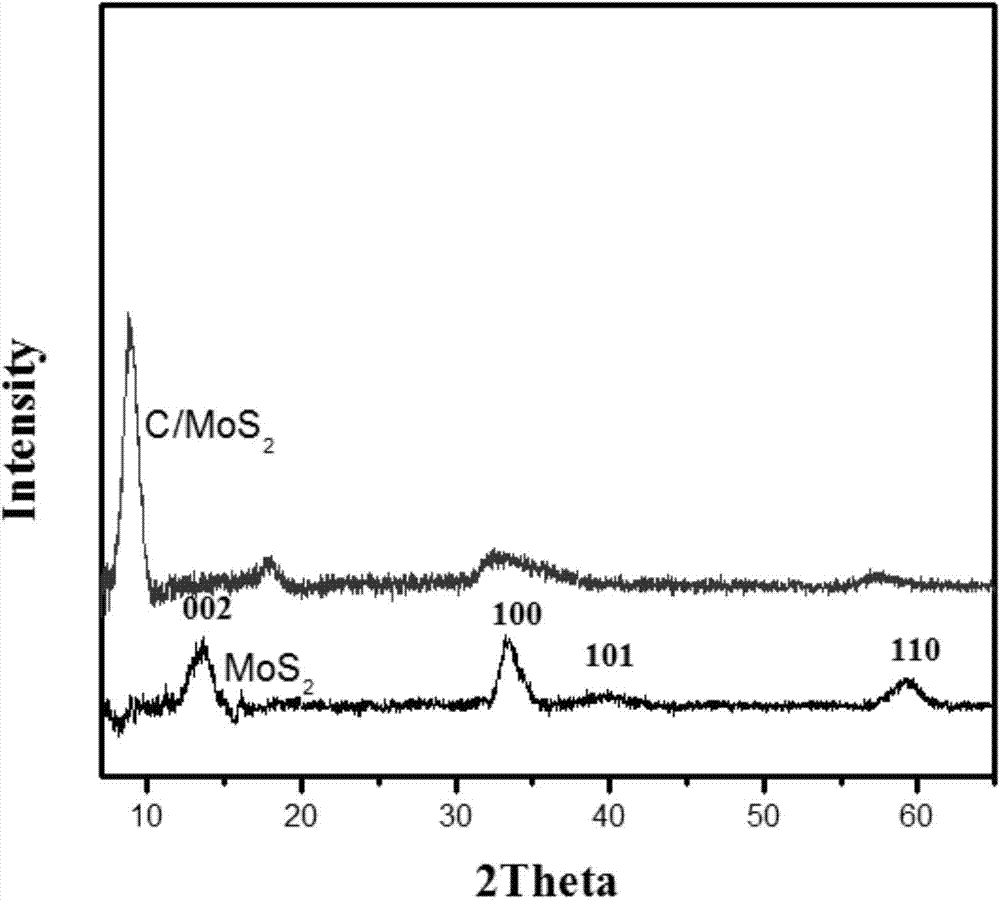

[0023] As-prepared carbon-doped MoS 2 Nanomaterials and carbon-free MoS 2 X-ray diffraction patterns of nanomaterials such as figure 1 As shown, it can be seen from the figure that the carbon-free MoS 2 Its characteristic peak is 002 at 14.38°, while carbon-doped MoS 2 There are two peaks at 9.73° and...

Embodiment 2

[0029] Take a certain amount of ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 7 o 24 4H 2 (2) and sodium thiocyanoacetate, dissolved in ethylene glycol and ultrapure water successively, its volume ratio is 4:1, at room temperature, stir 2h, make it fully dissolved, then adjust its pH=5 with hydrochloric acid, Finally, the above solution was transferred to an 80ml reaction kettle, and a solvothermal reaction was carried out at 180°C. After 12 hours of reaction, it was taken out, cooled to room temperature naturally, and then washed with ultrapure water and ethanol successively to collect black matter. Dry in a vacuum oven at 65°C for 10 hours to obtain MoS 2 Black powder, namely carbon doped MoS 2 nanomaterials.

Embodiment 3

[0031] Weigh a certain amount of molybdenum oxide and sodium thiocyanoacetate respectively according to the molar ratio of 1:2.5, dissolve them in ethylene glycol and ultrapure water in sequence, and the volume ratio is 4:1. At room temperature, stir for 2 hours to make it Fully dissolve, then adjust its pH to 5 with hydrochloric acid, and finally transfer the above solution to an 80ml reaction kettle, carry out a solvothermal reaction at 190°C, take it out after 20 hours of reaction, cool it naturally to room temperature, and then successively use a supernatant After washing with pure water and ethanol, the black substance was collected and dried in a vacuum oven at 60°C for 12 hours to obtain MoS 2 Black powder, namely carbon doped MoS 2 nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com