Triple-mesopore indium oxide formaldehyde gas-sensitive material and preparation method thereof

A technology of mesoporous silicon oxide and indium oxide, applied in chemical instruments and methods, nanotechnology for materials and surface science, inorganic chemistry, etc., can solve the problem of low working temperature, reduce contact, and speed up response recovery , Reduce the effect of sintering phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

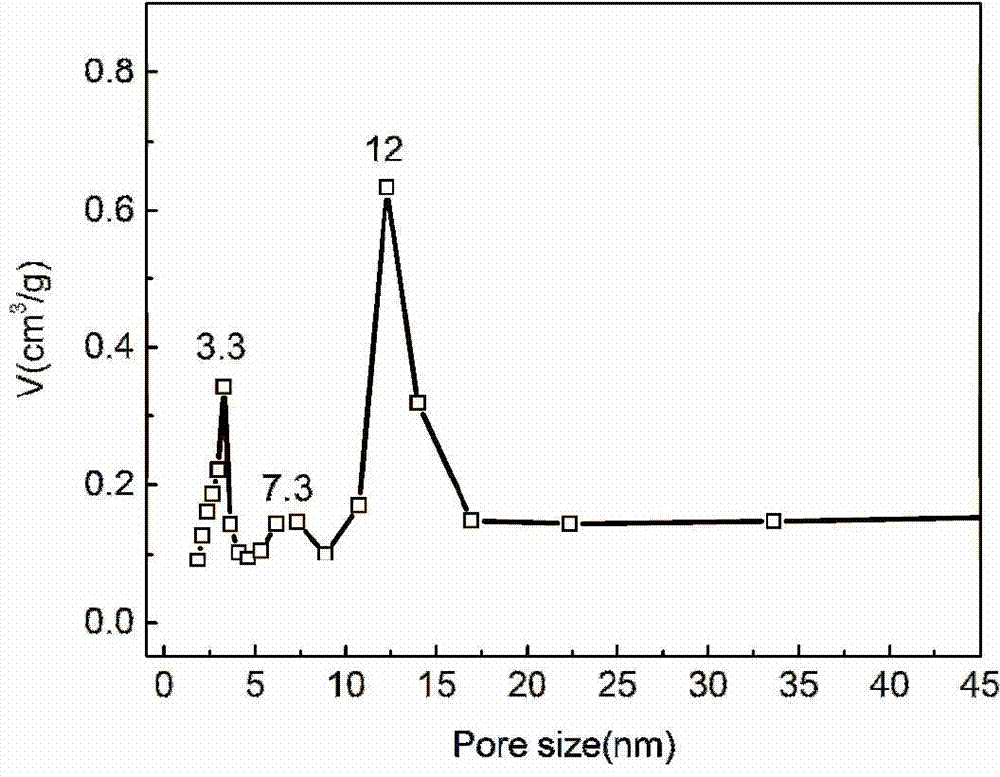

[0032] Get 6.0g surfactant P123, 216g water and 11.8g concentrated hydrochloric acid (37.5%, the same below) mix at 35 ℃, stir 12 hours and make surfactant all dissolve and disperse evenly, then add 6g n-butanol, stir 2 After 1 hour, add 12.9g tetraethyl orthosilicate TEOS, after stirring for 24 hours, transfer to a polytetrafluoroethylene bottle, then 40 degrees of hydrothermal reaction for 1 day, after natural cooling, separate the solid and liquid by suction filtration, wash with water, Dry naturally at room temperature to obtain surfactant-containing mesoporous silica. Then, the surfactant P123 in the sample obtained above (mesoporous silica containing surfactant, the same below) was removed by calcining at 550°C in air for 6 hours to obtain ordered mesoporous silica. The obtained ordered mesoporous silica has a specific surface area of 691m 2 / g, pore volume 0.52cm 3 / g, the pore size is about 4.8nm.

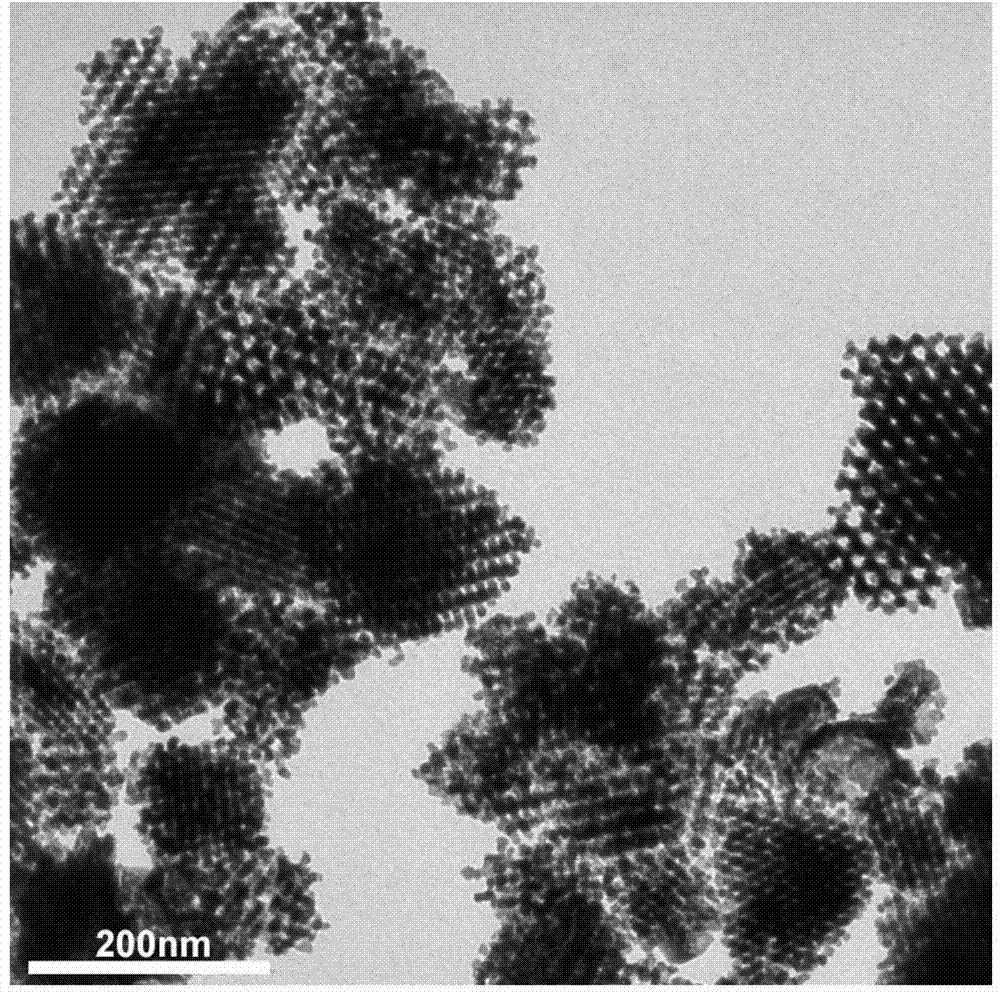

[0033] Use 0.6g of the above-mentioned treated mesoporous silica ...

Embodiment 2

[0035] Mix 6.0g of surfactant P123, 216g of water and 11.8g of concentrated hydrochloric acid at 35°C, stir for 1-12 hours until the surfactant is completely dissolved and dispersed evenly, then add 6g of n-butanol, stir for 2 hours, then add 12.9 g of tetraethyl orthosilicate TEOS, stirred for 24 hours, transferred to a polytetrafluoroethylene bottle, followed by hydrothermal reaction at 80 degrees for 1 day, after natural cooling, solid-liquid separation by suction filtration, washing with water, and natural drying at room temperature, that is Obtained mesoporous silica containing surfactant. After the surfactant P123 in the sample obtained above was removed by calcination at 550°C in air for 6 hours, ordered mesoporous silica was obtained. The obtained ordered mesoporous silica has a specific surface area of 809m 2 / g, pore volume 0.66cm 3 / g, the pore size is about 6.5nm.

[0036] Use 0.6g of the above-mentioned treated mesoporous silica as a hard template, disperse i...

Embodiment 3

[0038] Mix 6.0g of surfactant P123, 216g of water and 11.8g of concentrated hydrochloric acid at 35°C, stir for 1-12 hours until the surfactant is completely dissolved and dispersed evenly, then add 16.72g of 6g of n-butanol, and stir for 2 hours, Add 12.9g tetraethyl orthosilicate TEOS, stir for 24 hours, transfer to a polytetrafluoroethylene bottle, then 100 degrees hydrothermal reaction for 1 day, after natural cooling, separate solid-liquid by suction filtration, wash with water, and dry naturally at room temperature , that is, mesoporous silica containing surfactant is obtained. After the surfactant P123 in the sample obtained above was removed by calcination at 550°C in air for 6 hours, ordered mesoporous silica was obtained. The obtained ordered mesoporous silica has a specific surface area of 860m 2 / g, pore volume 0.76cm 3 / g, the pore size is about 7.9nm.

[0039] Use 0.6g of the above-mentioned treated mesoporous silica as a hard template, disperse it into 10g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com