A process for preparing high-purity silicon steel grade magnesium oxide from magnesium hydroxide

A magnesium hydroxide and silicon steel grade technology, applied in the direction of magnesium oxide, etc., can solve the problems of long process flow, unstable product quality, and low purity, and achieve the effect of short process flow, meeting industrial production requirements, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

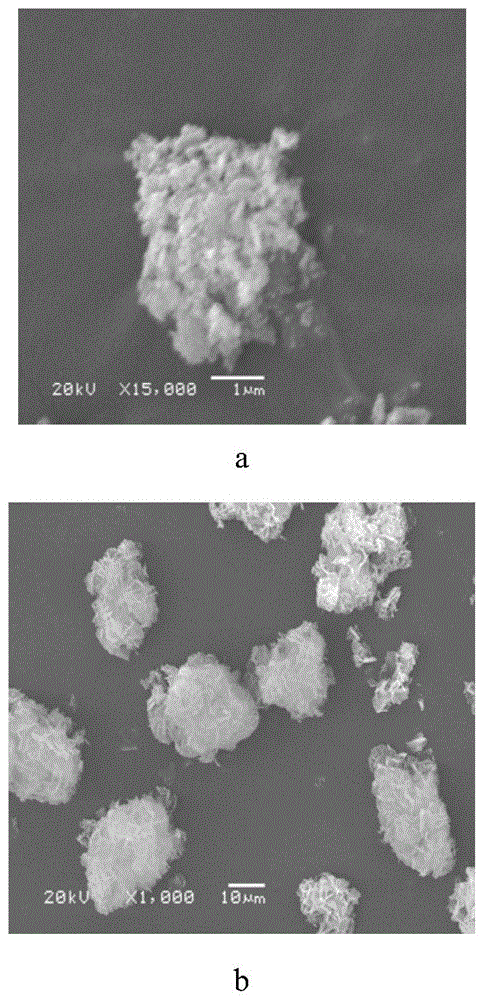

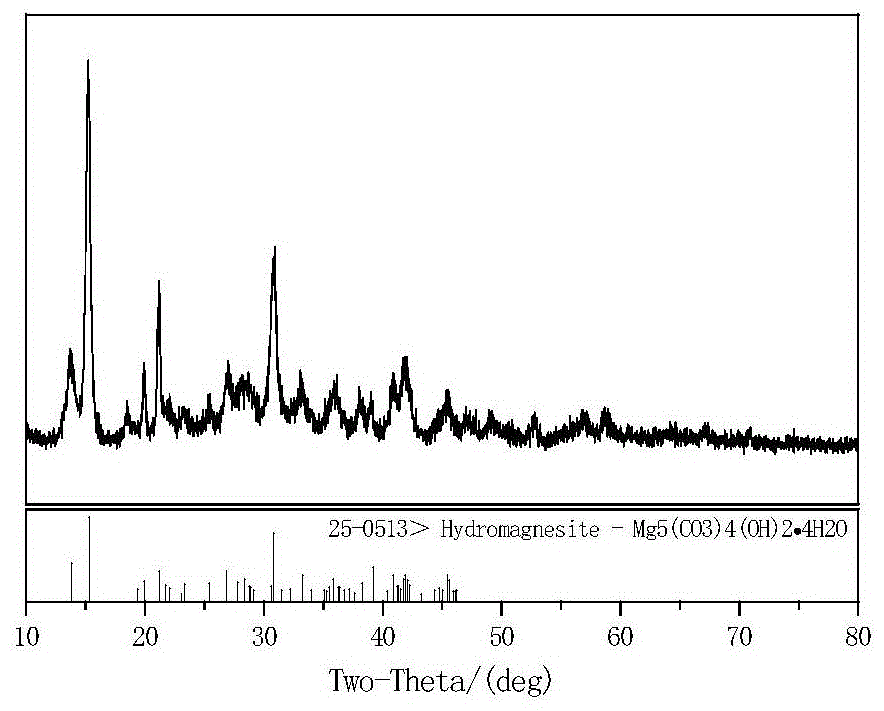

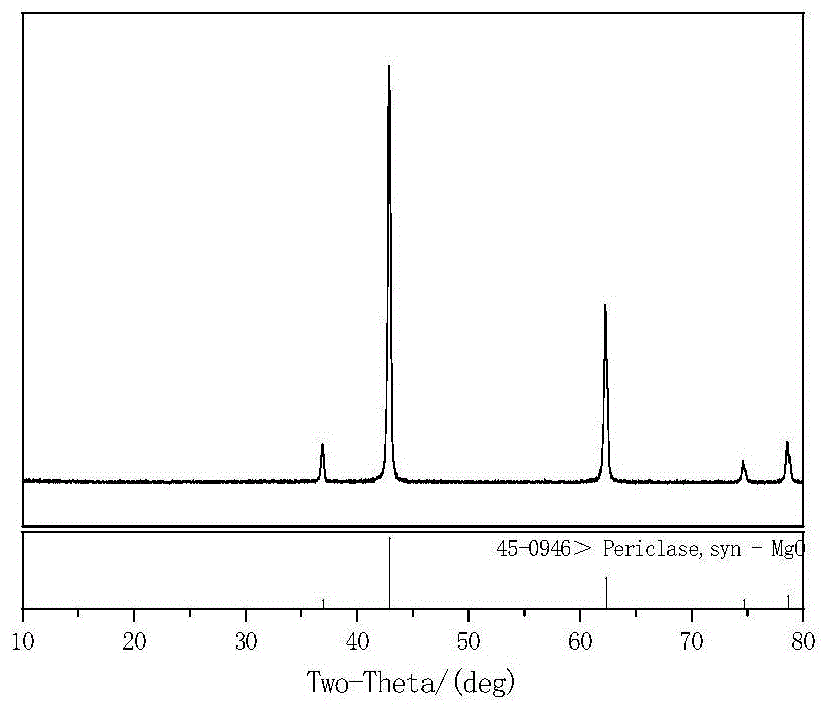

[0028] Put magnesium hydroxide into the muffle furnace, set the heating rate to 5°C / min, raise the temperature to 650°C, and keep it warm for 0.5h; take 10g of magnesium oxide obtained by light burning, put it into the reaction kettle, and add 200mL of deionized water, Raise the temperature to 80°C and stir thoroughly. After reacting for 0.5 hours, cool down the reactor to 75°C. At this time, adjust the ammonium bicarbonate metering pump, and dropwise add hydrogen carbonate with a concentration of 50g / L to the reactor at a rate of 0.2L / h. ammonium solution, fully stirred and reacted for 3 hours; the resulting suspension was filtered, washed, and dried at 100°C for 24 hours to obtain a precursor; the obtained precursor was placed in a muffle furnace, and the heating rate was set to 5°C / min. Raise the temperature to 1100° C. and keep it warm for 1.5 hours to obtain high-purity silicon steel grade magnesium oxide with a purity of 99.5%. The product profile is as follows figure 1...

Embodiment 2

[0030] Put magnesium hydroxide into the muffle furnace, set the heating rate to 7°C / min, raise the temperature to 550°C, and keep it warm for 2 hours; take 10g of magnesium oxide obtained by light burning, put it into the reaction kettle, and add 250mL of deionized water to heat up Fully stir at 85°C and react for 1 hour; after that, cool down the reactor to 60°C, at this time, adjust the ammonium bicarbonate metering pump, and add ammonium bicarbonate with a concentration of 50g / L dropwise to the reactor at a rate of 0.2L / h solution, fully stirred and reacted for 3 hours; the resulting suspension was filtered, washed, and dried at 110°C for 24 hours to obtain a precursor; to 1150° C., heat preservation for 1 hour, and obtain high-purity silicon steel-grade magnesium oxide with a purity of 99.4%. The magnesium oxide product has regular appearance and uniform particle size.

Embodiment 3

[0032] Put magnesium hydroxide into the muffle furnace, set the heating rate to 9°C / min, raise the temperature to 700°C, and keep it warm for 1.5h; take 10g of magnesium oxide obtained by light burning, put it into the reaction kettle, and add 150mL of deionized water, Raise the temperature to 75°C and stir thoroughly, and react for 1 hour; after that, cool down the reactor to 65°C, at this time, adjust the ammonium bicarbonate metering pump, and dropwise add hydrogen carbonate with a concentration of 50g / L to the reactor at a rate of 0.3L / h Ammonium solution, fully stirred and reacted for 2.5 hours; the resulting suspension was filtered, washed, and dried at 110°C for 20 hours to obtain a precursor; the obtained precursor was placed in a muffle furnace, and the heating rate was set to 4°C / min , the temperature was raised to 1050° C., and the temperature was maintained for 1.5 hours to obtain high-purity silicon steel grade magnesium oxide with a purity of 99.4%. The magnesium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com