Method for making activated carbon by using wild peach pit shells

A technology for preparing activated carbon and core shell, which is applied in the field of preparing activated carbon from pecan shell and achieves the effects of firm texture, developed voids and solving the problem of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

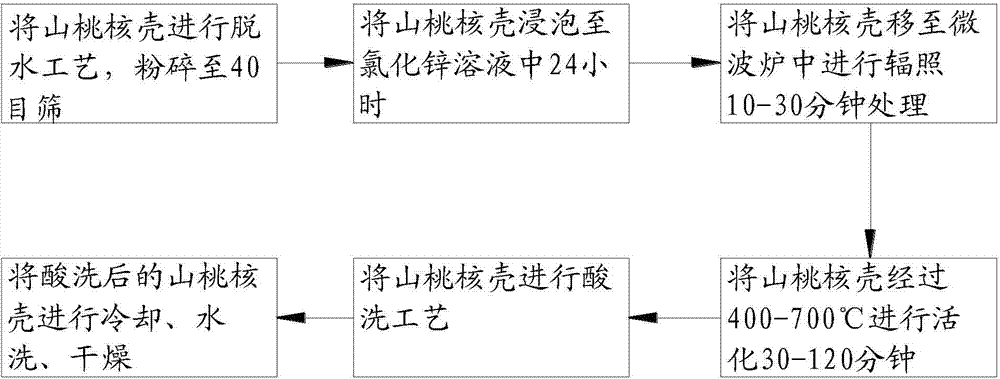

Method used

Image

Examples

Embodiment example 1

[0023] (1) drying the pecan core shell at 120°C for 12 hours to dehydrate;

[0024] (2) The dried raw material is pulverized through a 40-mesh sieve;

[0025] (3) Soak in 60% zinc chloride solution for 24 hours by solid-liquid ratio of 1:2;

[0026] (4) Place the soaked raw materials in a 400W microwave oven, and irradiate them with microwaves for 30 minutes;

[0027] (5) placing the raw materials treated by microwave irradiation in an activation furnace at 600°C for 90 minutes;

[0028] (6) adopting the dilute hydrochloric acid solution that volume ratio is 1:9 boils 30 minutes;

[0029] (7) Rinse the activation material with tap water so that its pH value is 6-7;

[0030] (8) The finished activated carbon can be obtained after the washed raw materials are placed in an oven for drying;

[0031] (9) The iodine adsorption value of the mountain peach core-shell activated carbon in this example is 1068mg / g.

Embodiment example 2

[0033] (1) Dry the pecan core shell at 120° C. for 12 hours to dehydrate.

[0034] (2) Crushing the dried raw material through a 40-mesh sieve.

[0035] (3) Soak in 60% zinc chloride solution for 24 hours according to the solid-to-liquid ratio of 1:2.

[0036] (4) Place the soaked raw materials in a 500W microwave oven and irradiate them with microwaves for 20 minutes.

[0037] (5) Place the raw materials treated by microwave irradiation in an activation furnace at 700° C. for 60 minutes for activation.

[0038] (6) Use dilute hydrochloric acid solution with a volume ratio of 1:9 to boil for 30 minutes.

[0039] (7) Rinse the activated material with tap water so that its pH value is close to 6-7.

[0040] (8) The finished activated carbon can be obtained after the washed raw materials are dried in an oven.

[0041] (9) The iodine adsorption value of the mountain peach core-shell activated carbon in this example is 1132mg / g.

Embodiment example 3

[0043] (1) Dry the pecan core shell at 120° C. for 12 hours to dehydrate.

[0044] (2) Crushing the dried raw material through a 40-mesh sieve.

[0045] (3) Soak in 60% zinc chloride solution for 24 hours according to the solid-to-liquid ratio of 1:2.

[0046] (4) Place the soaked raw materials in a 700W microwave oven and irradiate them with microwaves for 15 minutes.

[0047] (5) Place the raw materials treated by microwave irradiation in an activation furnace at 400° C. for 120 minutes for activation.

[0048] (6) Use dilute hydrochloric acid solution with a volume ratio of 1:9 to boil for 30 minutes.

[0049] (7) Rinse the activated material with tap water so that its pH value is close to 6-7.

[0050] (8) The finished activated carbon can be obtained after the washed raw materials are dried in an oven.

[0051] (9) The iodine adsorption value of the mountain peach core-shell activated carbon in this example is 1351mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com