Capacitor lead welding bench

A wire welding and workbench technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inconvenient operation, and achieve the effects of reducing occupational diseases, reducing health damage, and ensuring physical health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

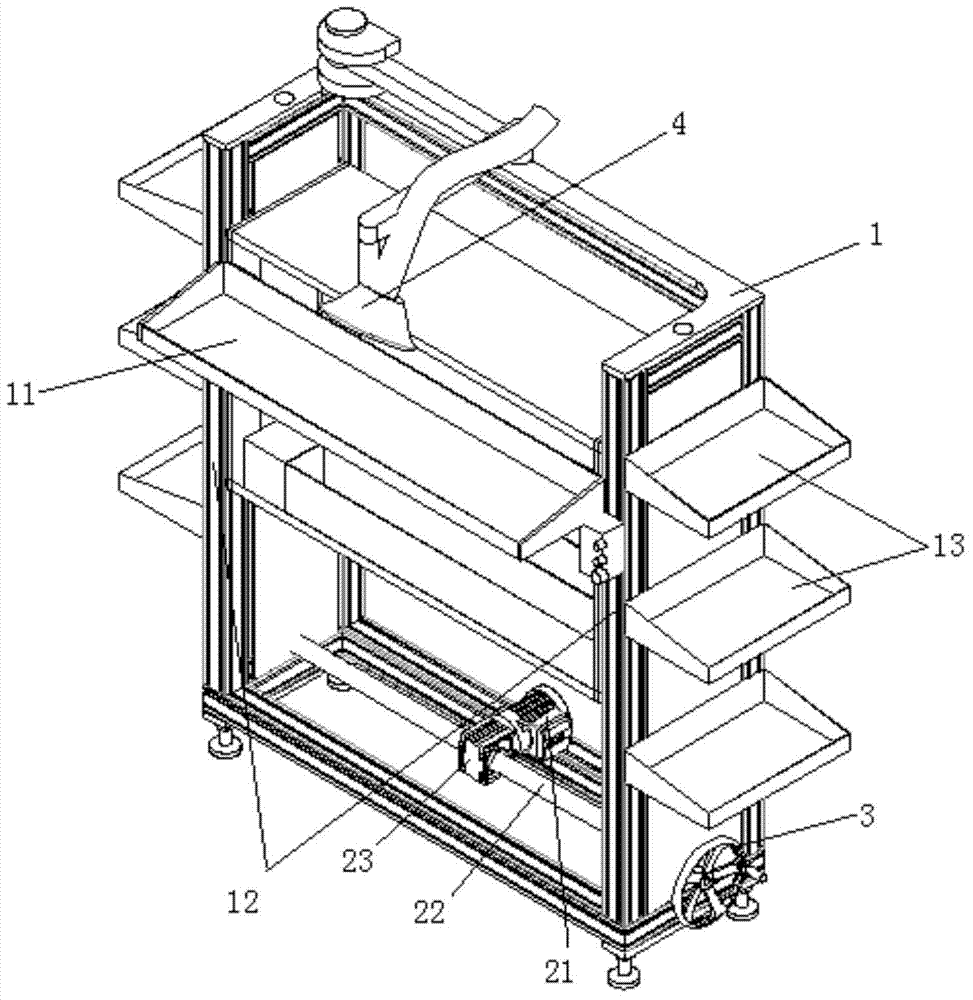

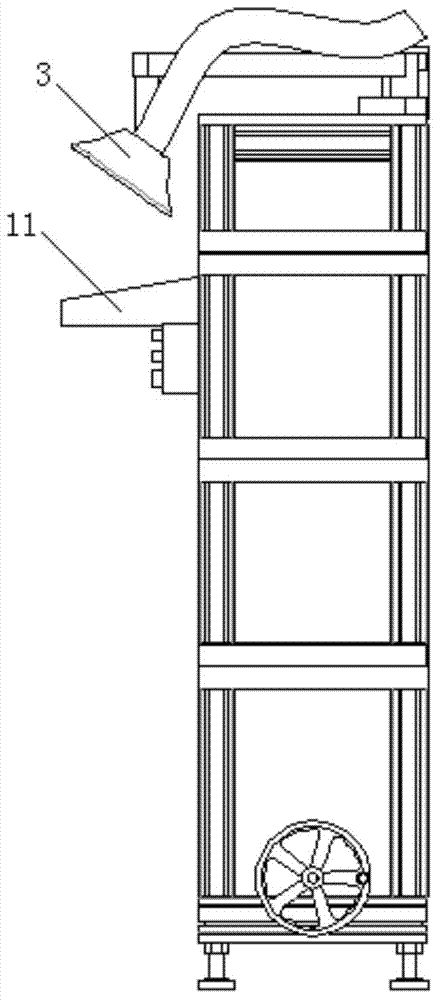

[0031] see Figure 1-3 , a capacitor lead wire welding workbench, including a frame body 1 and a control device, the frame body 1 is provided with at least two guide rails 12 and at least one worktable 11, the control device includes a controller, a servo motor 21, a speed reducer Machine 23, horizontal lead screw 22, gear I, gear II and vertical lead screw, described controller is connected with described servo motor 21, and described servo motor 21 is connected with described reducer 23, and described reducer 23 is connected with described reducer 23 The horizontal lead screw 22 is connected, the horizontal lead screw 22 is fixedly connected with the gear I, the gear I meshes with the gear II, the gear II is fixedly connected with the vertical lead screw, and the working The side of the table top 11 is provided with a connecting body, and the vertical lead screw is screwed with the internal thread of the connecting body. The work table 11 is provided with at least two slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com