Sauce-fragrance E-cigarette nicotine liquid

An e-cigarette liquid and sauce-flavored technology, applied in the field of e-cigarettes, can solve problems such as restricting the development of e-cigarettes, affecting the quality, taste, and aroma of e-cigarettes, and not fully meeting the needs of consumers for smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

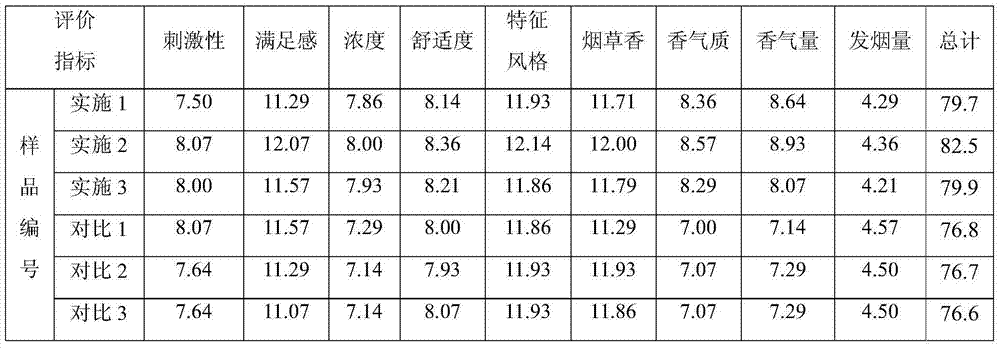

Embodiment 1

[0077]A sauce-flavored e-cigarette liquid, comprising the following raw material components by weight percentage: 18% of flue-cured tobacco leaf extract, 3.5% of tobacco essence, 5% of Moutai Prince wine, 2.5% of taste and flavor regulator, and 3% of deionized water , edible glycerin 8%, and the balance 60% is propylene glycol.

[0078] Among them, the alcoholized flue-cured tobacco leaves are stored in the Maotai-flavor liquor cellar, that is, the flue-cured tobacco leaves are dried in an oven at 40°C for 3 hours, cooled to room temperature, crushed with a pulverizer, and screened to 40-100 mesh. Then, extract with deionized water as a solvent, wherein the mass ratio of tobacco leaves to water is 1:3, weigh 100g of tobacco powder and place it in a 1L Erlenmeyer flask, and add 300ml of deionized water. Ultrasonic extraction is then carried out, the ultrasonic extraction temperature is 40°C, and the ultrasonic extraction time is 4h. Then, let it settle for 4 hours, filter it w...

Embodiment 2

[0083] A sauce-flavored electronic cigarette liquid, which contains the following raw material components by weight percentage: 19% of oriental tobacco leaf extract, 5.5% of tobacco essence, 7% of Lai Mao wine, 3.5% of taste and flavor regulator, and 6% of deionized water %, edible glycerin 9%, and the balance 50% is propylene glycol.

[0084] Among them, the alcoholized oriental tobacco leaves are stored in the Maotai-flavor liquor cellar, that is, the oriental tobacco leaves are dried in an oven at 40°C for 3 hours, cooled to room temperature, pulverized with a pulverizer, screened to 40-60 mesh, and soaked in solvent ethanol. The mass ratio of tobacco leaves to ethanol was 1:3, 100g of tobacco powder was weighed and placed in a 1L Erlenmeyer flask, 300ml of ethanol was added, and then ultrasonic extraction was performed. The ultrasonic extraction temperature was 60°C, and the ultrasonic extraction time was 4h. Then, let it stand and settle for 4 hours, filter it with a sand...

Embodiment 3

[0089] A sauce-flavored electronic cigarette liquid, which contains the following raw material components by weight percentage: Burley tobacco leaf extract 20%, tobacco essence 4%, expensive wine 5.5%, taste and flavor regulator 3%, deionized water 4.5% %, edible glycerin 8%, and the balance 55% is propylene glycol.

[0090] Among them, the alcoholized Burley tobacco leaves are stored in the sauce-flavored liquor cellar, that is, the Burley tobacco leaves are dried in an oven at 40°C for 3 hours, cooled to room temperature, pulverized with a pulverizer, screened to 40-100 mesh, and then washed with a solvent. Deionized water leaching, wherein the mass ratio of tobacco leaves to water is 1:3.5, weigh 100g of tobacco powder and place it in a 1L Erlenmeyer flask, add 350ml of deionized water. Ultrasonic extraction is then carried out, the ultrasonic extraction temperature is 50°C, and the ultrasonic extraction time is 4h. Then, let it settle for 4 hours, filter it with a sand co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com