Capillary drip irrigation system

A technology of capillary and capillary bundles, applied in horticulture, botanical equipment and methods, cultivation, etc., can solve the problems of high cost of drip irrigation system, easy blockage of drippers, high operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

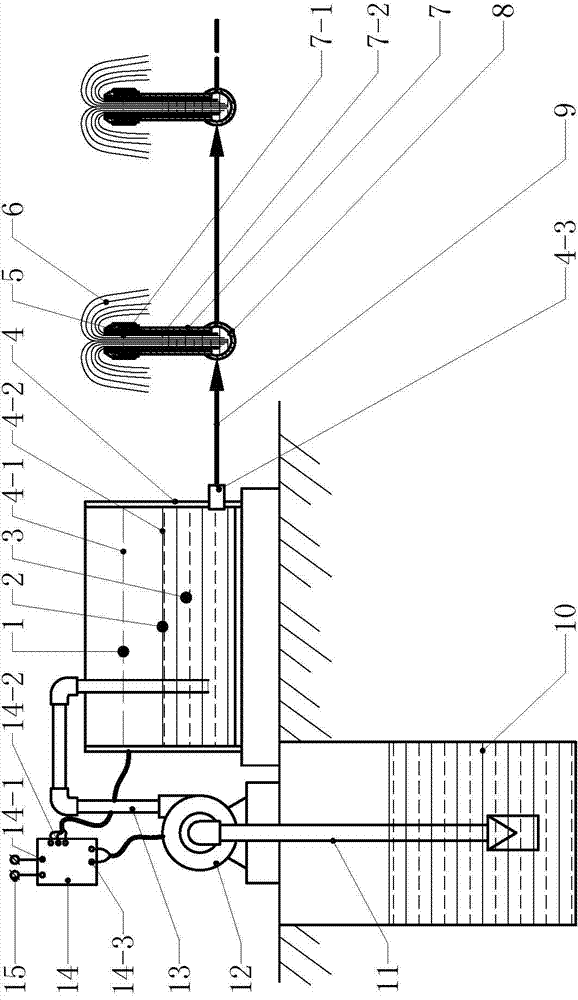

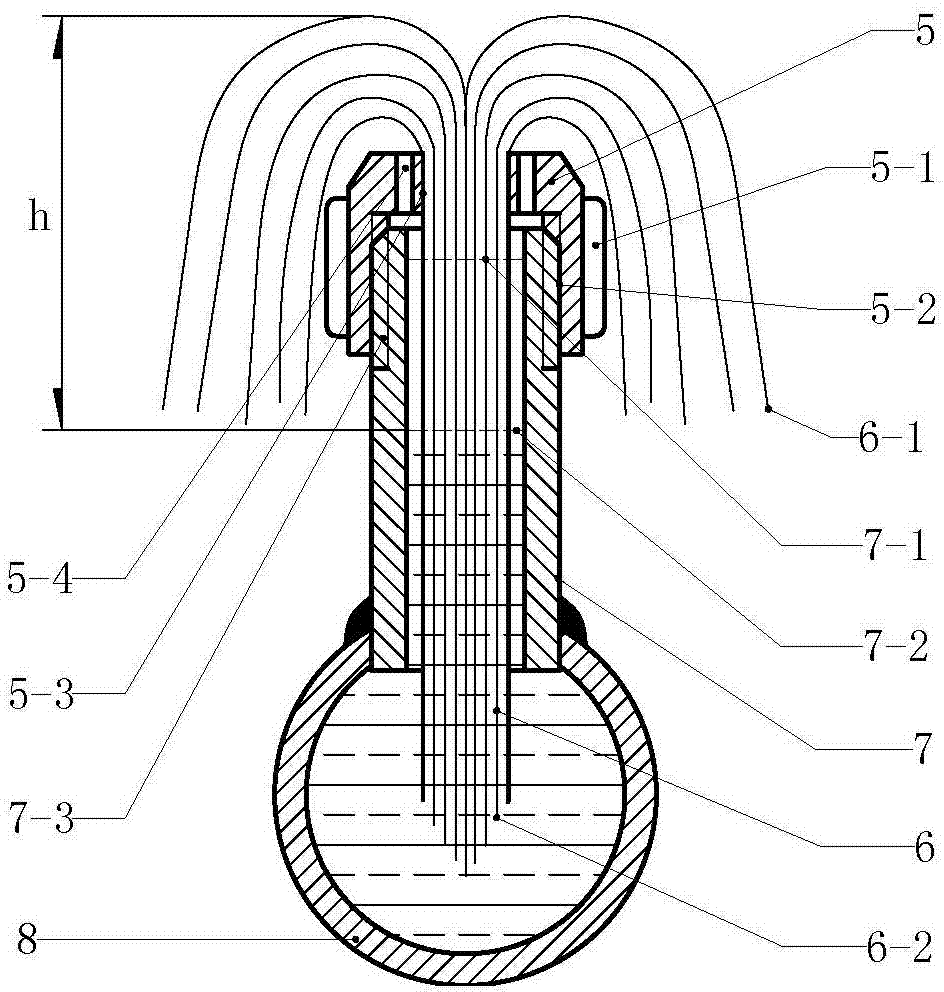

[0015] Example 1 figure 1In the illustrated embodiment, a capillary drip irrigation system consists of a water level controller (14), a balance tank (4), a water supply pipe (9), a water diversion branch pipe (8), a water diversion capillary (7) and a capillary dripper, wherein , the water level controller (14) has a power input interface (14-1), a signal input interface (14-2) and a control output interface (14-3), and the water supply pipe (9) and the diversion branch pipe (8) respectively have The branch interface, the capillary dripper is composed of the dripper cover (5) and the capillary bundle (6), the dripper cover (5) is a rotary structure, and the center of the rotary body of the dripper cover (5) has a bayonet (5-3) , the capillary bundle (6) is installed in the bayonet (5-3) of the dripper cover (5), there is a vent hole (5-4) on the top of the dripper cover (5), and the dripper cover (5) There is a hand-twist ear flap (5-1) on the outside of the wall, and the h...

Embodiment 2

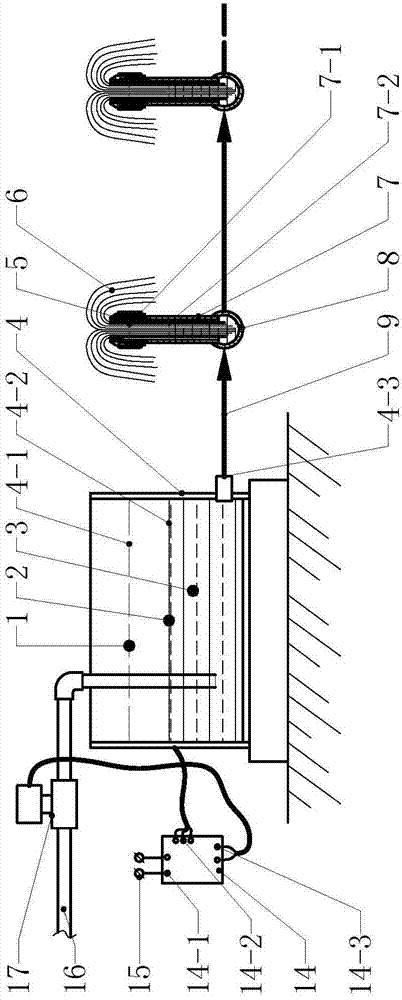

[0016] Example 2 figure 2 In the illustrated embodiment, on the basis of the first embodiment, the water source of the balance water tank (4) comes from a mountain stream, and there is a water delivery pipe (16) between the mountain stream and the balance water tank (4), and the water delivery pipe (16 ) has a solenoid valve (17), and the control output interface (14-3) of the water level controller (14) is connected to the coil of the solenoid valve (17). Other structures are the same as those of the first embodiment, and will not be repeated here.

[0017] The above-mentioned embodiment utilizes the capillary principle to realize the purpose of drip irrigation, and the water supply pipeline does not need to have pressure. When in use, the water supply of the water supply pipe (9) is provided by the balance water tank (4), and the water level of the balance water tank (4) is controlled by the water level controller (14) to realize intelligent water replenishment. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com