Sintered body and amorphous film

A sintered body and amorphous film technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of inaccessibility, different composition systems, small refractive index, etc., and achieve the purpose of inhibiting film peeling, The effect of less membrane rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

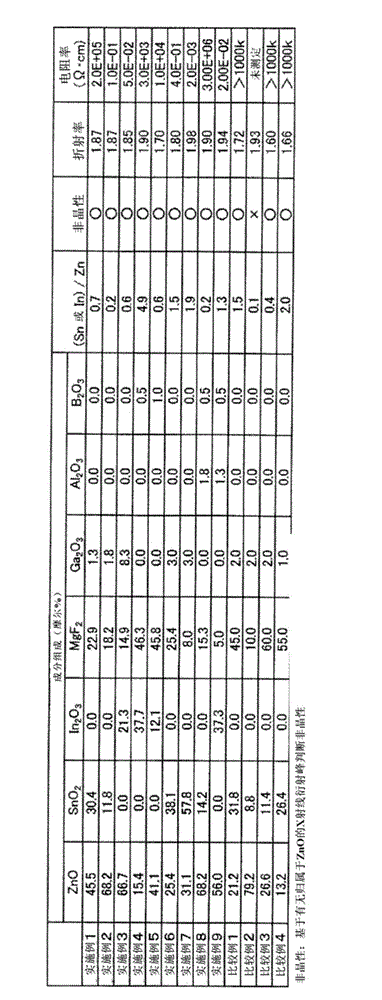

Embodiment 1)

[0044] Prepare ZnO powder equivalent to 3N of 5 μm or less and SnO equivalent to 3N with an average particle size of 5 μm or less 2 Powder, MgF equivalent to 3N with an average particle size of 5 μm or less 2 powder, Ga below 5 μm equivalent to 3N 2 o 3 pink. Then, ZnO powder, SnO 2 Powder, MgF 2 Powder and Ga 2 o 3 powder formulated into ZnO:SnO 2 : MgF 2 : Ga 2 o 3 =45.5: 30.4: 22.9: 1.25 mol% of the compounding ratio, after mixing it, at a temperature of 850°C and a pressure of 250kgf / cm 2 The powder material is hot-pressed and sintered under certain conditions to obtain a sintered body for ion plating. Ion plating was performed using this sintered body. As a result, it was confirmed that stable ion plating was possible and that the produced film was an amorphous film. In addition, the refractive index of this film reaches 1.87 (wavelength 550nm).

Embodiment 2)

[0046] Prepare ZnO powder equivalent to 3N of 5 μm or less and SnO equivalent to 3N with an average particle size of 5 μm or less 2 Powder, MgF equivalent to 3N with an average particle size of 5 μm or less 2 powder, Ga below 5 μm equivalent to 3N 2 o 3 pink. Then, ZnO powder, SnO 2 Powder, MgF 2 Powder and Ga 2 o 3 powder formulated into ZnO:SnO 2 : MgF 2 : Ga 2 o 3 = 68.21: 11.76: 18.24: 1.79 mol% of the compounding ratio, after mixing it, at a temperature of 850°C and a pressure of 250kgf / cm 2 The powder material is hot-pressed and sintered under certain conditions to obtain a sintered body for ion plating. Ion plating was performed using this sintered body. As a result, it was confirmed that stable ion plating was possible and that the produced film was an amorphous film. In addition, the refractive index of this film reaches 1.87 (wavelength 550nm).

Embodiment 3)

[0048] Prepare ZnO powder equivalent to 3N with an average particle size of 5 μm or less and In with an average particle size of 5 μm or less equivalent to 3N 2 o 3 Powder, MgF equivalent to 3N with an average particle size of 5 μm or less 2 powder, Ga below 5 μm equivalent to 3N 2 o 3 pink. Then, ZnO powder, In 2 o 3 Powder, MgF 2 Powder and Ga 2 o 3 powder formulated as ZnO:In 2 o 3 : MgF 2 : Ga 2 o 3 = 66.7: 21.3: 14.9: 8.3 mol% of the mixture, after mixing, at a temperature of 850 ° C, a pressure of 250 kgf / cm 2 The powder material is hot-pressed and sintered under certain conditions to obtain a sintered body for ion plating. Ion plating was performed using this sintered body. As a result, it was confirmed that stable ion plating was possible and that the produced film was an amorphous film. In addition, the refractive index of this film reaches 1.85 (wavelength 550nm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com