Method for manufacturing smooth polycrystalline silicon film and array substrate

A technology of polysilicon and polysilicon layer, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. It can solve the problems of liquid crystal display quality degradation, thin-film transistor failure, etc., achieve small surface roughness, improve quality, and eliminate partial The effect of too much electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

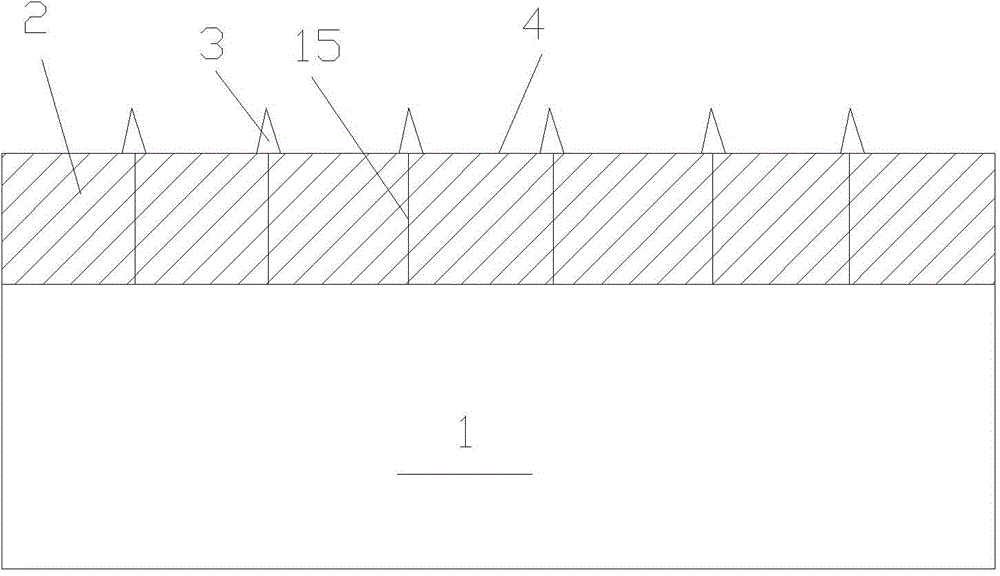

Embodiment 1

[0032] A first polysilicon layer having a thickness of 450 angstroms was formed on a glass substrate, and a plurality of bumps were formed on the surface of the first polysilicon layer. It is detected that the surface roughness of the flat surface of the first polysilicon layer is 100-150 angstroms. The glass substrate 1 was immersed in a secco etching solution, and etched until there were no bumps but pits on the surface of the first polysilicon layer. The detection found that the depth D of the pit was about 300 angstroms. Next, a second amorphous silicon layer is formed on the surface of the first polysilicon layer. The thickness H of the second amorphous silicon layer is about 500 angstroms, and the second amorphous silicon layer includes a recessed filled region corresponding to the pit and a non-filled region surrounding the filled region. Next, use 420mJ / cm 2 The laser heats the second amorphous silicon layer until the material in the filled area is completely melted...

Embodiment 2

[0034] A first polysilicon layer having a thickness of 450 angstroms was formed on a glass substrate, and a plurality of bumps were formed on a flat surface of the first polysilicon layer. It is detected that the surface roughness of the flat surface of the first polysilicon layer is 100-150 angstroms. use SF 6 with Cl 2 The mixed gas used as an etching medium etches the glass substrate 1 until there are pits instead of bumps on the surface of the first polysilicon layer. The detection found that the depth D of the pit was about 300 angstroms. Next, a second amorphous silicon layer is formed on the surface of the first polysilicon layer. The thickness H of the second amorphous silicon layer is about 500 angstroms, and the second amorphous silicon layer includes a recessed filled region corresponding to the pit and a non-filled region surrounding the filled region. Next, turn the glass substrate 90 degrees with the normal line of the glass substrate as the axis, and then us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com