Novel intelligent coal conveying control system based on FCS on-site bus technology

A fieldbus and control system technology, applied in general control system, control/adjustment system, program control, etc., can solve the problems of long motor idling time, low degree of automation, and less information collected by equipment, so as to reduce the amount of coal fed into the furnace Calorific value difference loss, improving accuracy and reliability, saving hardware quantity and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

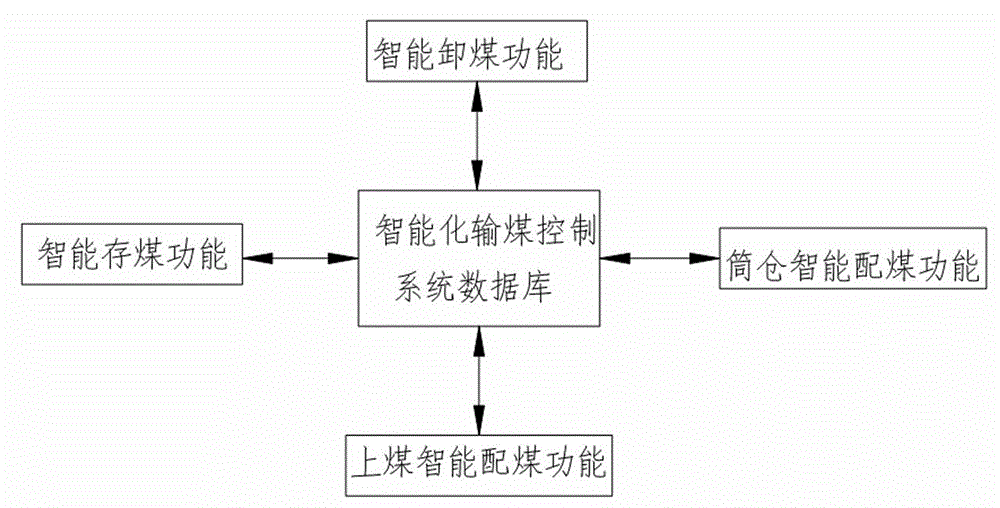

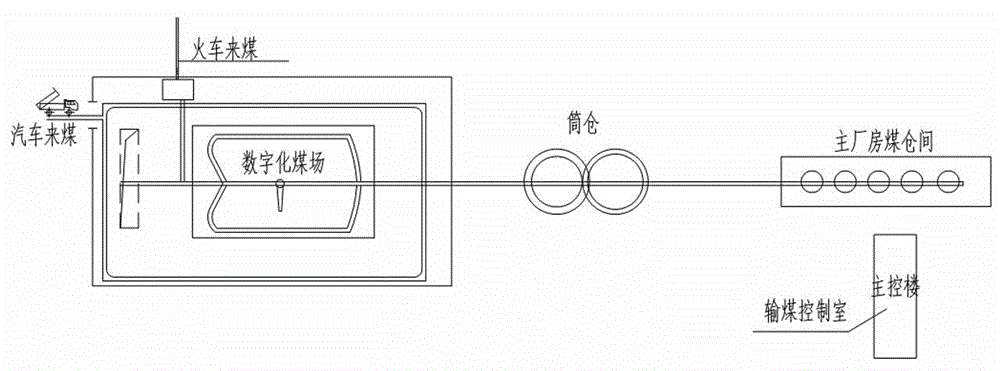

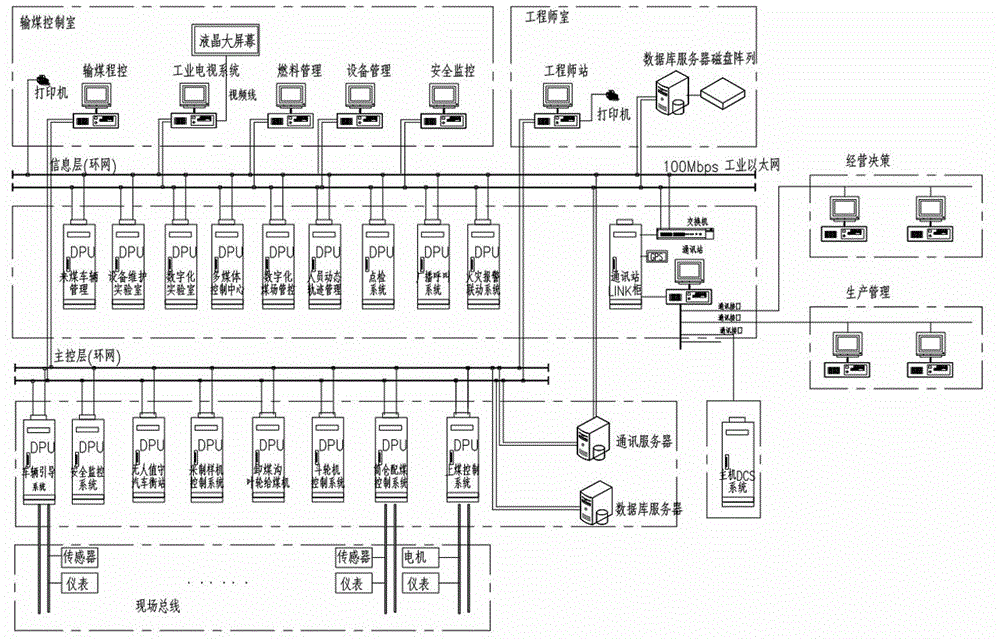

[0020] see Figure 1-Figure 3 . The present invention provides a new type of intelligent coal handling control system based on FCS field bus technology, absorbing various new technologies and new equipment suitable for coal handling systems, as well as mature and advanced control systems developed by domestic automation manufacturers. FCS field bus control technology is adopted, and the operating path is preset according to system work requirements such as coal unloading, coal storage, coal mixing, bunkering, and coal loading. During the operation of the coal handling system, by calling the real-time data of each coal handling subsystem in the database, combined with the host DCS coal mixing, warehouse mixing requirements and other information, the preset system function and the best operation path are automatically selected, and fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com