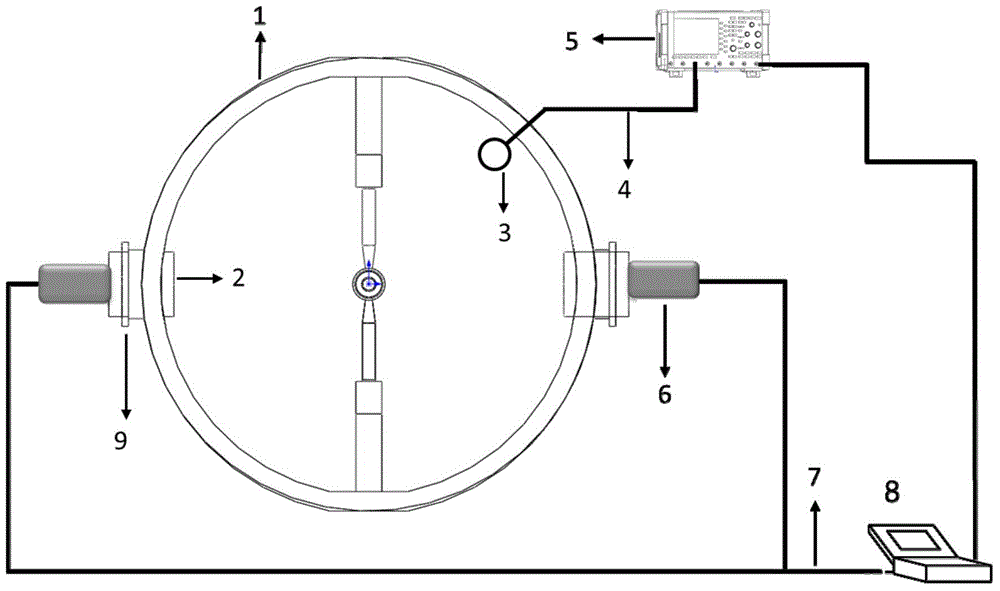

Automatic frequency tuning control system

A control system and automatic tuning technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of large power loss, long stabilization time, unfavorable high-frequency cavity rapid operation, and reduce power loss. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1: 1 10mm5mm to ,,2.5mm,5,1mm。 example 2:, 1 , 1 or 。 example 3

[0019] The number of tuners mentioned is proposed according to the requirements of electric field tuning and frequency tuning. If the influence on the electric field is small, only the frequency range is required for calculation; if the electric field is required to be high, it is necessary to tune the electric field The tuner is set up locally, and the calculation method is to use the industry-wide 3D electromagnetic field software Microwave Studio to calculate the electric field and frequency changes. The size range is as mentioned above, and the coverage can meet the requirements. (Example 1: If you need a circular tuner with a diameter of 10mm to insert 5mm to get the operating frequency, if you use two tuners of the same size, the length of each inserted tuner will be close to 2.5mm, if there are 5 The same tuner, each insertion length is close to 1mm. Example 2: If the high-frequency cavity is small, one tuner can meet the needs of frequency modulation, and the fine-tunin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com