Method for measuring longitudinal wave velocity of anisotropic material

An anisotropy and measurement method technology, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as complex measurement steps, low measurement accuracy, and low amplitude of reflected echo signals, and shorten the measurement period. Effects of measurement accuracy and simplification of measurement procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

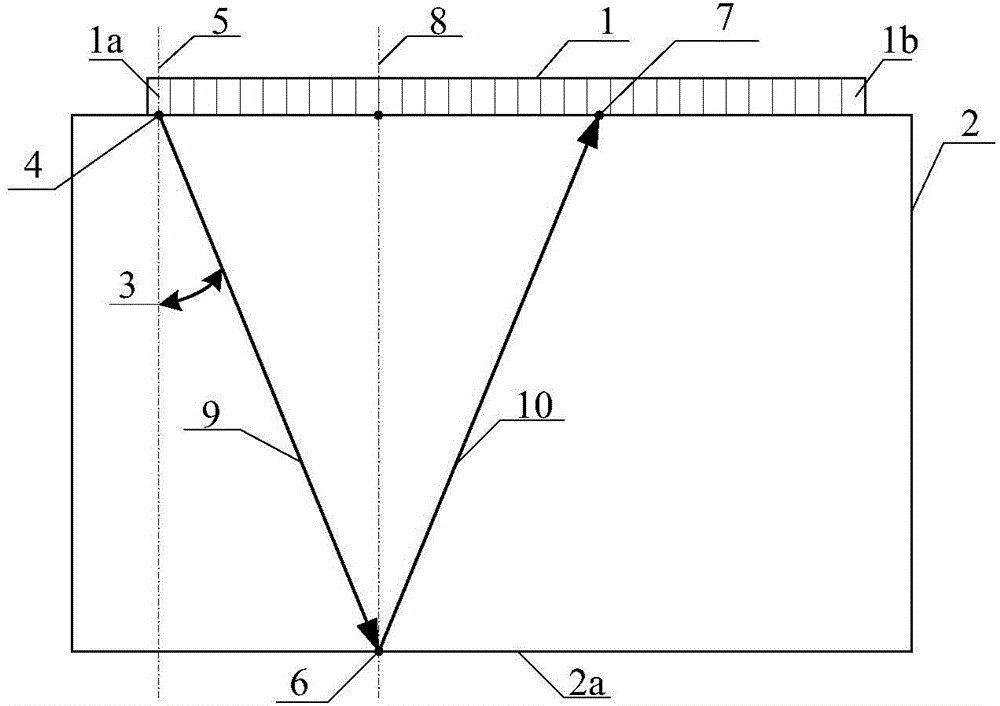

[0069] In this embodiment, a carbon fiber-reinforced epoxy resin-based composite laminate sample is taken as an example to describe in detail the measurement method of the longitudinal wave sound velocity. The thickness of the tested sample is H=10mm, and the measurement steps are as follows:

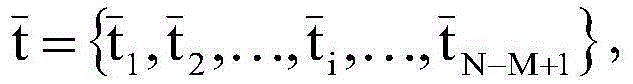

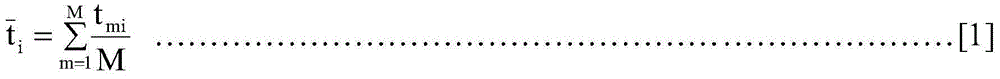

[0070] 1. Ultrasonic echo data acquisition and storage: select a phased array ultrasonic linear array probe, the number of array elements N=32, the array element spacing p=0.6mm, and the array element width a=0.5mm; the phased array ultrasonic linear array The probe is placed on the upper surface of the tested sample after smearing the coupling agent, and the position of the phased array ultrasonic linear array probe is not moved during the measurement of the longitudinal wave sound velocity; the phased array ultrasonic flaw detector is set so that the phased array ultrasonic linear array probe The No. 1 to No. 3 array element chips from the left end emit ultrasonic waves sequentially. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com