Powder paint detection spraying table

A technology of powder coating and test chamber, which is used in measuring devices, analytical materials, instruments, etc., can solve the problems of difficult to completely remove coating particles and affect the detection effect, and achieve the effect of fast cleaning, good effect and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

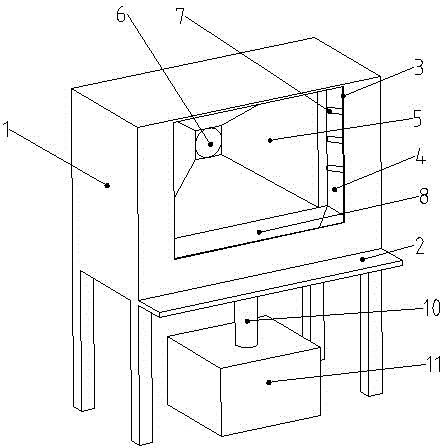

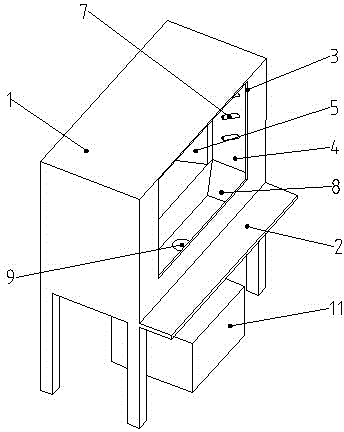

[0012] combine figure 1 and figure 2 Illustrate the specific embodiment of the present invention, the box body 1 of cube, one side surface of box body 1 is provided with opening 3, and the inside of opening 3 is formed as test cavity 4, and the test cavity 4 is provided with suction port 6, and suction port 6 Connected with the exhaust fan, it is characterized in that: the innermost wall of the test chamber 4 is a square pyramid-shaped test slope 5, and the square pyramid-shaped test slope 5 is recessed to the inside of the box body 1, and the air suction port 6 is opened on the test slope 5 The center of the test cavity 4 is connected with a water nozzle 7 on the side wall of the test chamber 4, and the water nozzle of the water nozzle 7 faces the test slope 5, and the bottom of the test cavity 4 has a collection tank 8, and the bottom of the collection tank 8 The center has a water hole 9, and the water hole 9 is connected with a water pipe 10, and the water pipe 10 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com