A method and system for treating and utilizing phenolic water using a rotary kiln

A rotary kiln, phenol water technology, applied in water/sewage treatment, treatment of discharged materials, water/sludge/sewage treatment, etc., can solve problems such as phenol water treatment, save cooling water, long time and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

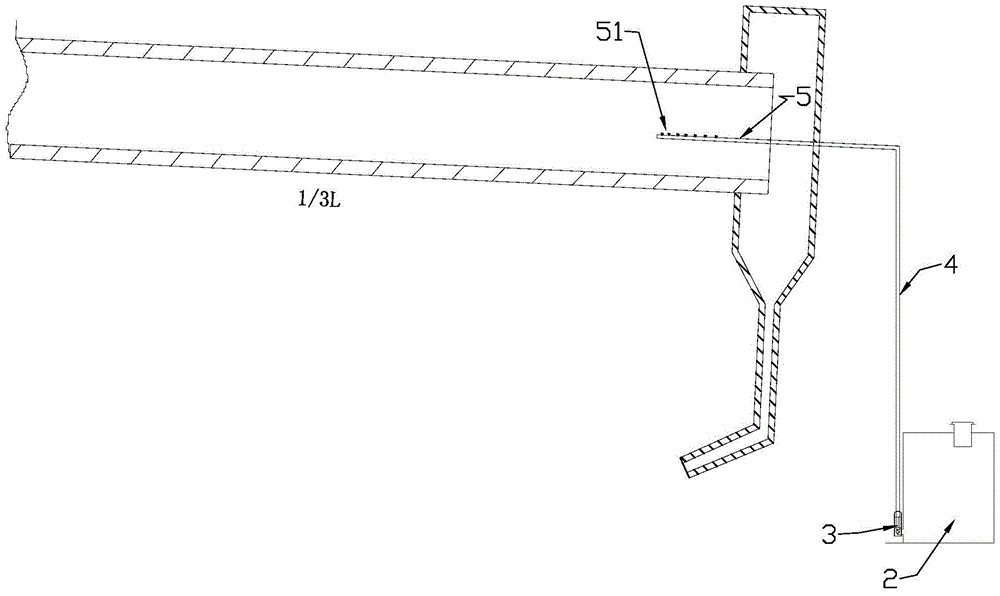

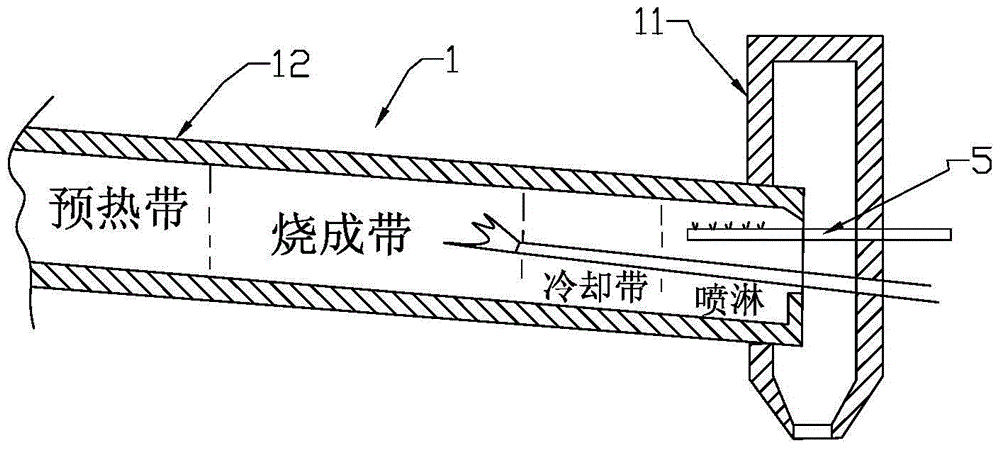

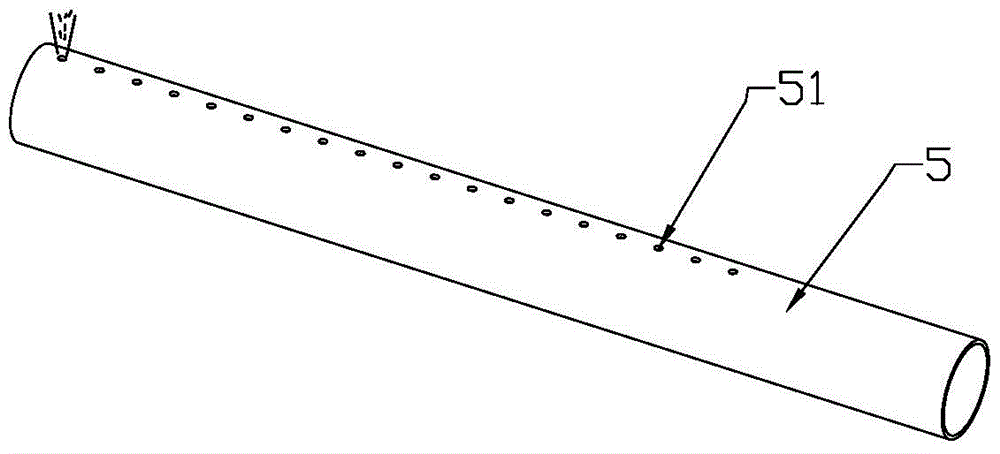

[0036] A method and system for treating and utilizing phenol water using a rotary kiln, such as Figure 1 to Figure 3 As shown, it involves a rotary kiln 1, a phenol water tank (box) 2, an electric pump 3, a pipeline 4, and a nozzle 5.

[0037] Among them, the rotary kiln 1 can be divided into cement rotary kiln, burnt gemstone rotary kiln, kaolin rotary kiln, lime rotary kiln, etc. according to the purpose. There are a large number of fired products in this type of rotary kiln in the factory, and the fired products generally need to be cooled. . The following is an example of a rotary kiln for burnt gemstones.

[0038] The rotary kiln 1 includes the kiln head part 11 (kiln head cover), the kiln body part 12 and the kiln tail part, wherein the kiln head is the discharge part of the rotary kiln, the diameter is larger than the diameter of the rotary kiln, and the seal is realized by stainless steel scales and the kiln body. Body part 12 is the main body of the rotary kiln (ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com